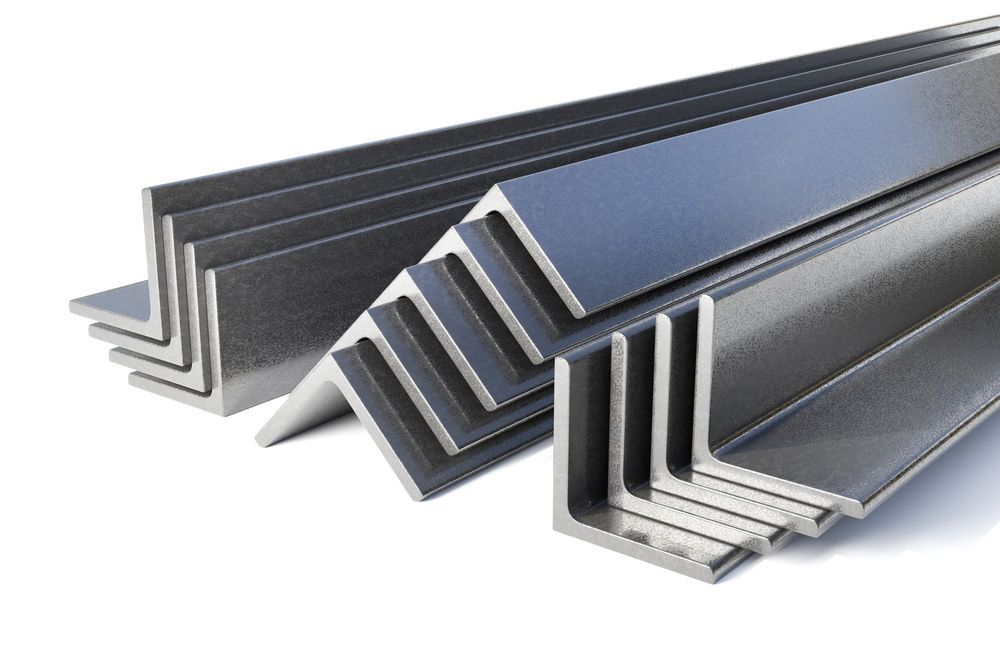

Aluminum Angle

Structural Aluminum Angle in 1100, 3003, & 6061 Grades

Action Stainless stocks aluminum angle in a wide range of sizes and thicknesses to meet the demands of structural bracing, framing, and decorative architectural elements. Aluminum angle is valued for its high strength, lightweight form, corrosion resistance, and ease of fabrication, making it ideal for both interior and exterior applications.

We offer aluminum angle in

1100, 3003,

and 6061 grades. These alloys are commonly used for their combination of machinability, durability, and aesthetic surface finish—suitable for everything from industrial support frames to polished architectural edges.

Finishes & Processing Services

Aluminum angle is supplied in a standard mill finish, which offers a smooth and clean surface suitable for most general applications. When a refined look or additional corrosion protection is needed, brushed and anodized finishes can be provided on request. Action Stainless supports full in-house processing including saw cutting, drilling, milling, and forming. These capabilities allow us to deliver aluminum angle accurately fabricated and cut to specification—whether for one-off components or large-scale structural builds.

Available Styles and Materials

We stock

aluminum angle in:

1100 Aluminum Angle

Soft, highly formable, and corrosion-resistant; ideal for decorative trim, light framing, and chemical applications

3003 Aluminum Angle

Strong and corrosion-resistant with good weldability; commonly used in brackets, supports, and architectural applications

6061 Aluminum Angle

High strength and excellent machinability; suited for structural framing, fabrication, and load-bearing components

Equal Leg Angles

Sizes from 3/4" x 3/4" x 1/8" up to 6" x 6" x 1/2"

Unequal Leg Angles

Available as special order

Mill Finish

Standard surface finish for general fabrication

Brushed/Anodized Finish

Available upon request for architectural and corrosion-sensitive installations

This variety of materials and profiles supports applications ranging from lightweight trim to robust structural reinforcement.

Aluminum Angle Specifications

Aluminum products used in angle fabrication are available in the following specifications:

Grades Offered: 1100, 3003, and 6061: selected for structural reliability, weldability, and clean extruded finish across structural and architectural applications.

Product Forms: Equal and unequal leg angles; custom-cut lengths and special profiles available.

Finishes:

Supplied in mill finish; brushed and anodized options provided on request.

Processing Capabilities: In-house saw cutting, CNC drilling and milling, forming, and fabrication support for both custom and high-volume orders

These material options and fabrication services support a wide range of industrial, architectural, and custom expanded metal applications.

Aluminum Angle Applications

Aluminum angle

is commonly used in:

Structural Fabrication:

Bracing supports, framing corners, stair stringers, base plates, mechanical housings

Architectural Projects:

Trim edges, decorative borders, canopy frames, window trims, column reveals

Industrial Equipment: Racks, machine guards, fixture frames, supports for panels, storage enclosures

Marine & Outdoor Use:

Bulkheads, mounting rails, dock reinforcements, canopy supports, deck edge trim

Signage & Display Systems: Sign frames, mounting tracks, kiosks, exhibit structures, banner stands