How Pickling and Passivation Extend the Life of Stainless Steel Components

In industries where sanitation, strength, and corrosion resistance are critical, stainless steel is a material of choice. But even this durable alloy requires proper finishing treatments to ensure its full performance potential. For manufacturers, processors, and fabricators working in environments like food production, chemical processing, marine, and pharmaceuticals, pickling and passivation are essential post-fabrication treatments that preserve the integrity and longevity of stainless steel components.

While both processes improve corrosion resistance, they differ in application and chemical function. Understanding how pickling and passivation work and when each is needed can help extend product lifespan, reduce maintenance cycles, and protect against contamination or breakdown in service.

Why Stainless Steel Still Needs Surface Treatment

Despite its corrosion-resistant properties, stainless steel is not immune to damage during fabrication. Cutting, welding, and forming can alter the surface chemistry or introduce contaminants that compromise the protective chromium oxide layer. This layer is what gives stainless steel its "stainless" property without it, the material becomes vulnerable to pitting, rusting, or surface staining.

Additionally, during manufacturing, iron particles from tooling or cross-contamination can embed on the surface. These contaminants may not be visible but can act as corrosion initiation sites over time. That’s where finishing processes like pickling and passivation come into play.

What Is Pickling?

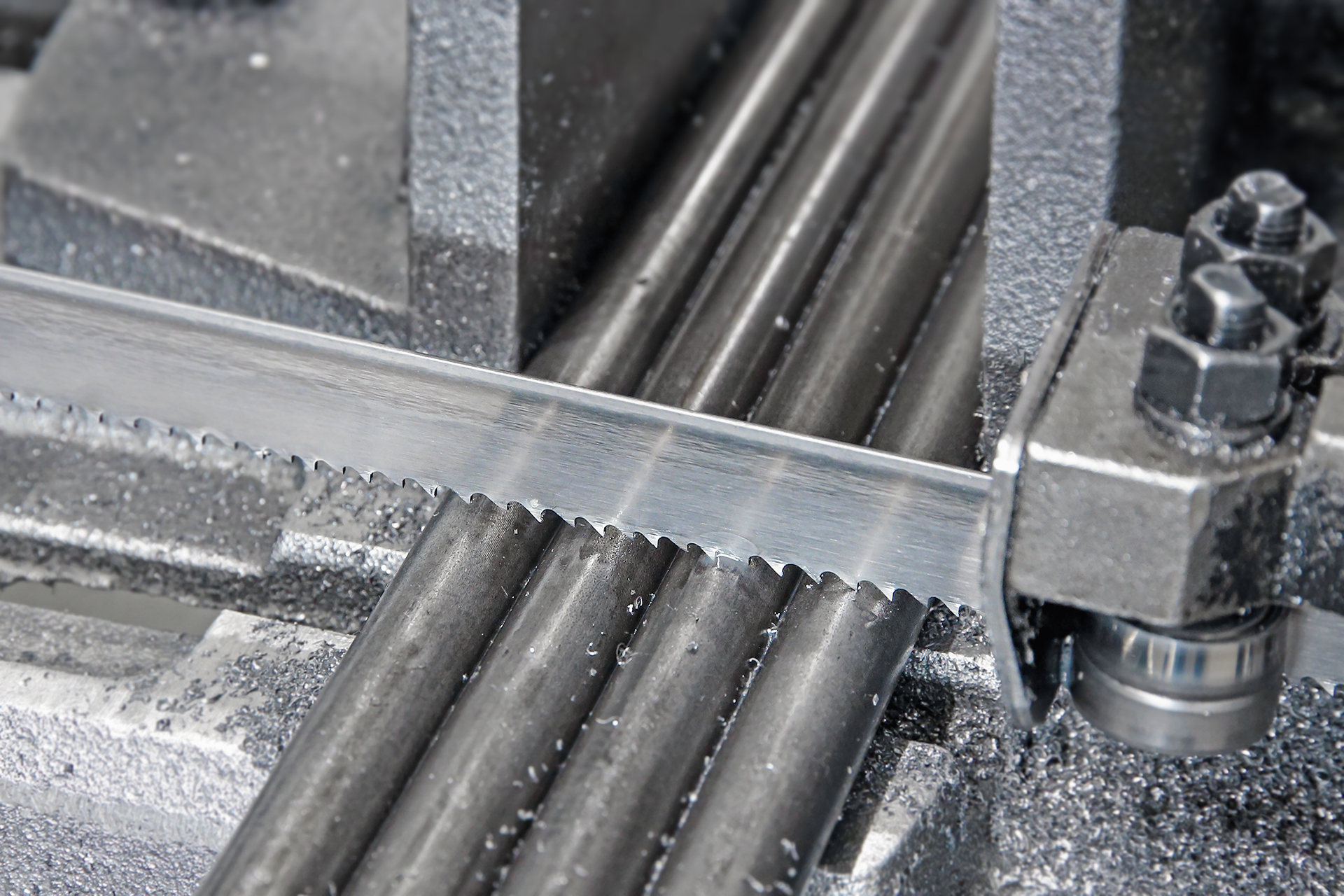

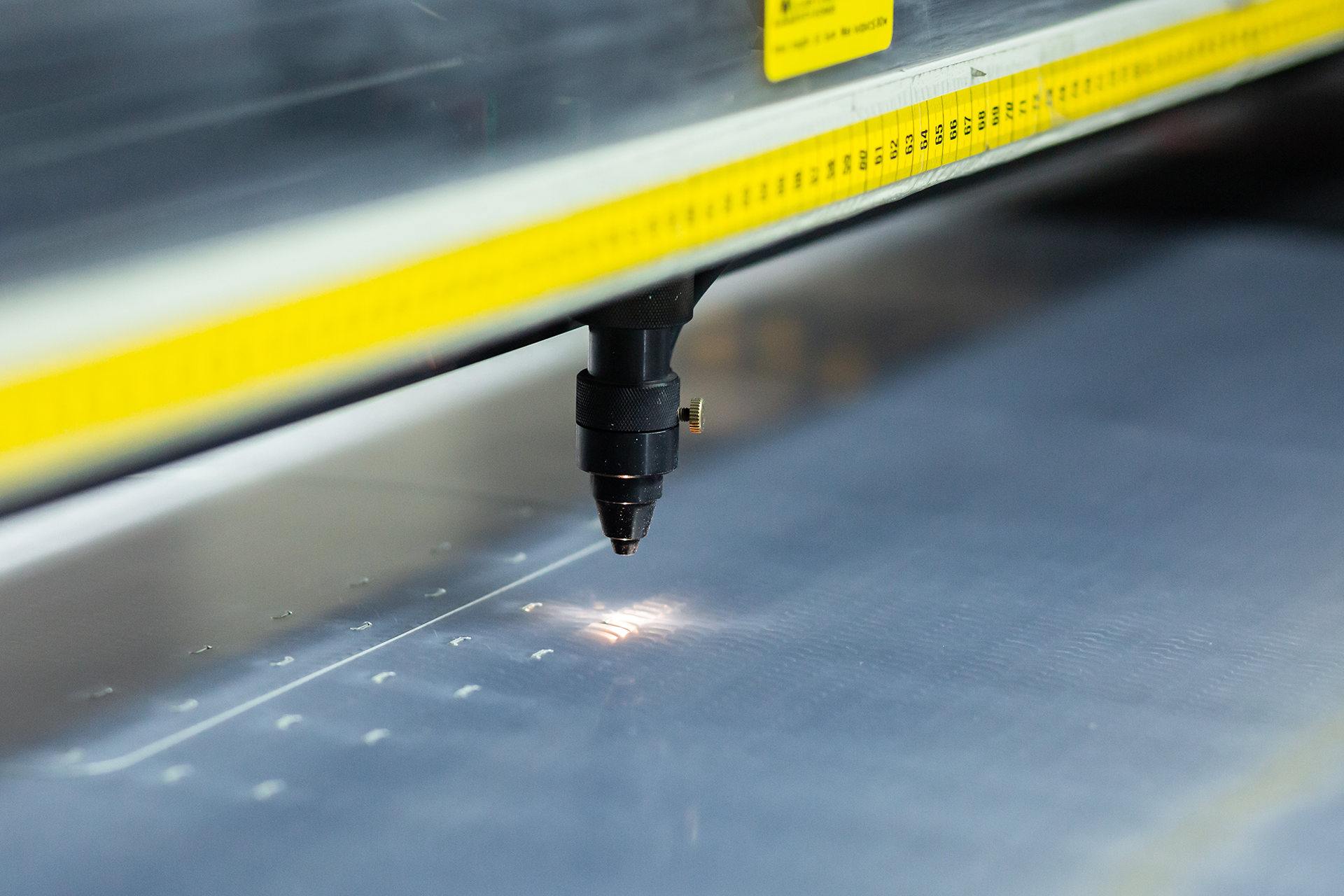

Pickling is a chemical process used to remove scale, weld burn, discoloration, and embedded contaminants from the surface of stainless steel. It involves the application of acid-based solutions, usually a mix of nitric and hydrofluoric acids, which dissolve the outer layer of scale and impurities left from high-heat or machining processes.

Pickling is most commonly used after:

- Welding or high-temperature forming

- Heavy machining or cutting

- Rolling or forging operations

- Heat treatment processes

By stripping away the damaged or contaminated outer surface, pickling restores the stainless steel to a clean, corrosion-resistant state.

What Is Passivation?

Passivation is a separate process focused on enhancing the natural protective layer of stainless steel. Instead of removing visible contaminants or scale, passivation uses a nitric or citric acid bath to strip away free iron particles on the surface without affecting the base metal. Once these iron particles are removed, oxygen in the air reacts with the surface chromium to reform a uniform, passive oxide layer.

Passivation is typically used:

- After machining or low-heat fabrication

- Following pickling, as a secondary treatment

- As a maintenance step to restore corrosion resistance

This treatment is especially valuable in cleanroom, food processing, pharmaceutical, and chemical settings, where microscopic surface integrity plays a major role in hygiene and performance.

Comparison Table: Pickling vs. Passivation

| Feature | Pickling | Passivation |

|---|---|---|

| Purpose | Removes scale, weld discoloration, oxides | Removes free iron and enhances oxide layer |

| Chemicals Used | Nitric + hydrofluoric acid | Nitric or citric acid |

| Surface Effect | Alters surface slightly; dull finish | Minimal change; retains original finish |

| Best After | Welding, heat treating, heavy fabrication | Machining, light forming, or post-pickling |

| Corrosion Resistance | Restores to corrosion-resistant condition | Enhances and stabilizes corrosion resistance |

| Common Applications | Heavy fabrication, structural components | Sanitary, pharmaceutical, food-grade parts |

Where These Treatments Matter Most

In stainless steel applications where hygiene, durability, or compliance is non-negotiable, surface condition is just as important as alloy selection. These sectors in particular depend heavily on pickling and passivation to protect their stainless components:

Food & Beverage Processing

Stainless steel tanks, valves, fittings, and conveyor components must remain free from contamination and surface pitting. Pickling is used after welding assemblies, while passivation is essential for restoring parts after cleaning or maintenance cycles.

Pharmaceutical & Biotech

In high-purity production environments, even small iron deposits or discolorations can trigger batch failures or microbial growth. Passivation ensures the inner surface of stainless piping and tanks maintains optimal corrosion resistance and meets regulatory standards.

Marine & Coastal Manufacturing

Salt exposure accelerates corrosion, especially if fabrication processes leave scale or contamination behind. Pickling removes these threats, and passivation keeps surface chromium levels high for long-term resistance.

Chemical Processing

Process vessels and piping exposed to aggressive chemicals need uniform surfaces. Pickling helps eliminate heat-tinted areas, while passivation prevents iron contamination that could trigger localized corrosion or reactions.

The Role of Proper Finishing in System Longevity

Failing to address surface condition post-fabrication can lead to costly consequences. Corrosion that begins at a weld seam or tooling mark may not appear immediately but can lead to pitting, system failures, contamination, or frequent replacements. By implementing proper pickling and passivation procedures, facilities can:

- Extend equipment life

- Reduce cleaning and maintenance intervals

- Avoid costly downtime or compliance issues

- Improve overall system hygiene and integrity

At Action Stainless, these benefits aren’t just theoretical they’re part of the value we deliver across food production facilities, energy systems, and high-spec industrial environments every day.

How Action Stainless Supports Finishing Standards

Action Stainless provides high-quality stainless steel tubing, fittings, sheet, bar, and other components used in demanding industries. With in-house value-added services including cutting, polishing, and sourcing assistance, we help fabricators and manufacturers maintain tight tolerances and cleanliness standards from the start.

Our inventory includes sanitary tubing and fittings commonly used in pickled and passivated conditions, giving customers confidence that their components meet food-grade, pharma-grade, and chemical resistance requirements. And when your application depends on long-term surface protection, our team is here to support your sourcing decisions with precision and product expertise.

Conclusion: Protecting Your Investment in Stainless

Pickling and passivation are not optional they’re essential steps in protecting stainless steel components from corrosion and wear. When properly applied, these treatments maintain the integrity of welds, preserve surface quality, and ensure your systems perform in line with industry expectations.

For manufacturers working in sanitation-sensitive or high-performance environments, partnering with a knowledgeable stainless supplier is key. Action Stainless supports this need with premium inventory and services that align with strict industry standards for finishing and fabrication.