Polished Stainless Steel in Architecture: Built to Perform and Impress

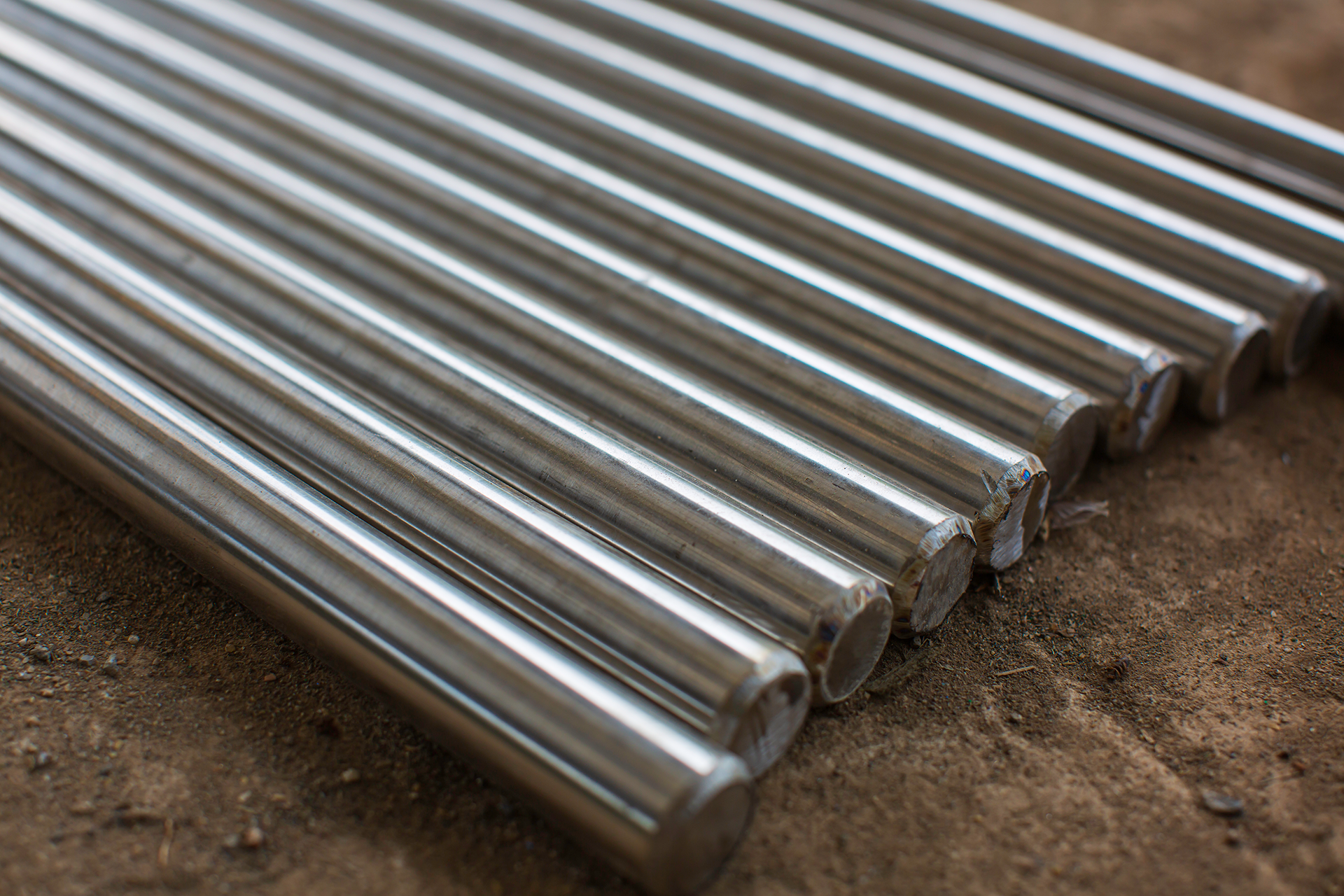

In the world of architectural design, aesthetics and performance must work in harmony. Whether you're outfitting a modern commercial kitchen, designing a public elevator system, or fabricating high-end decorative panels, polished stainless steel delivers both form and function. Its clean look, corrosion resistance, and ease of maintenance make it a material of choice for architects and fabricators seeking a professional, long-lasting finish.

Action Stainless supplies a wide selection of polished stainless steel sheet, bar, and tubing, all suited for architectural use. Combined with our in-house polishing and cutting services, we help ensure each project achieves its visual and performance goals.

1. Visual Appeal and Modern Design Versatility

One of the most obvious benefits of polished stainless steel is its ability to reflect and enhance modern design trends. With its clean, mirror-like surface or subtle brushed finish, polished stainless helps achieve a contemporary, high-end look in both commercial and public settings.

This is especially useful in:

- Elevator interiors, where light reflection enhances a sense of space

- Wall cladding or trim, adding visual depth and sleekness

- Kitchen surfaces, where smooth finishes emphasize hygiene and precision

Because Action Stainless offers multiple finish options #4 brushed, #8 mirror, and custom polishing we help ensure material matches the desired architectural aesthetic without compromising durability.

2. Surface Protection and Corrosion Resistance

Polishing stainless steel does more than improve looks, it enhances the surface layer by reducing imperfections where corrosion might start. This is especially critical in indoor-outdoor transition areas or moisture-prone environments like kitchens and restrooms.

Polished finishes provide:

- Smoother surfaces with fewer crevices

- Less risk of trapping debris or moisture

- Greater resistance to oxidizing agents in public or marine environments

When paired with proper passivation or electropolishing, these surfaces can maintain their appearance for decades.

3. Hygienic Properties for Food & Health Facilities

Hygiene is a driving concern in many of the industries that rely on architectural stainless steel. In commercial kitchens, hospitals, and pharmaceutical settings, the smooth surface of polished stainless steel allows for fast cleaning, easy sterilization, and reduced microbial retention.

The following table compares common finish types used in hygiene-focused applications:

| Finish Type | Roughness (Ra µin) | Typical Use | Cleanability |

|---|---|---|---|

| 2B | 10–40 | General industrial use | Moderate |

| #4 Brushed | 20–25 | Kitchens, food equipment, handrails | Good |

| #8 Mirror | <10 | Surgical areas, decorative cladding | Strong, corrosion-resistant, ideal for marine use |

Action Stainless stocks stainless grades like 304 and 316 with polished finishes that meet hygiene standards for food-safe and medical-grade environments. Combined with our sourcing and polishing capabilities, clients can rely on ready-to-use materials for sanitary environments.

4. Long-Term Value in High-Traffic Areas

Architectural installations in airports, office towers, commercial kitchens, and public venues must withstand frequent use without showing wear. Polished stainless steel is ideal here, offering scratch resistance and ease of maintenance that far outpaces painted metals or plastics.

Benefits include:

- Easy restoration: Surfaces can be re-polished or refinished as needed

- UV resistance: No fading or chalking, even in daylight-exposed areas

- Sustainability: 100% recyclable at end-of-life

Action Stainless offers polishing services that reduce in-field labor, ensuring consistent finish across every panel, post, or fixture before it even reaches the jobsite.

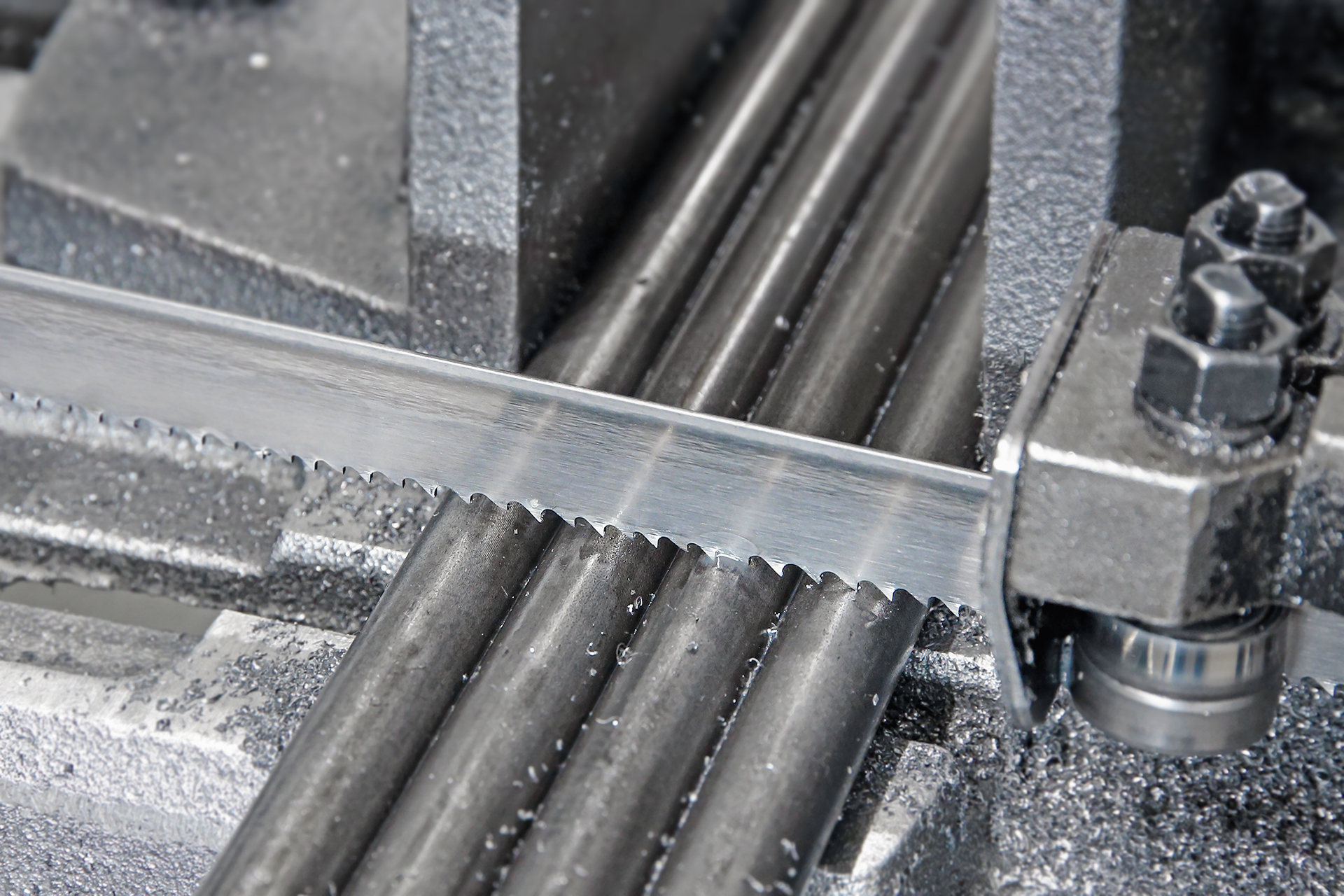

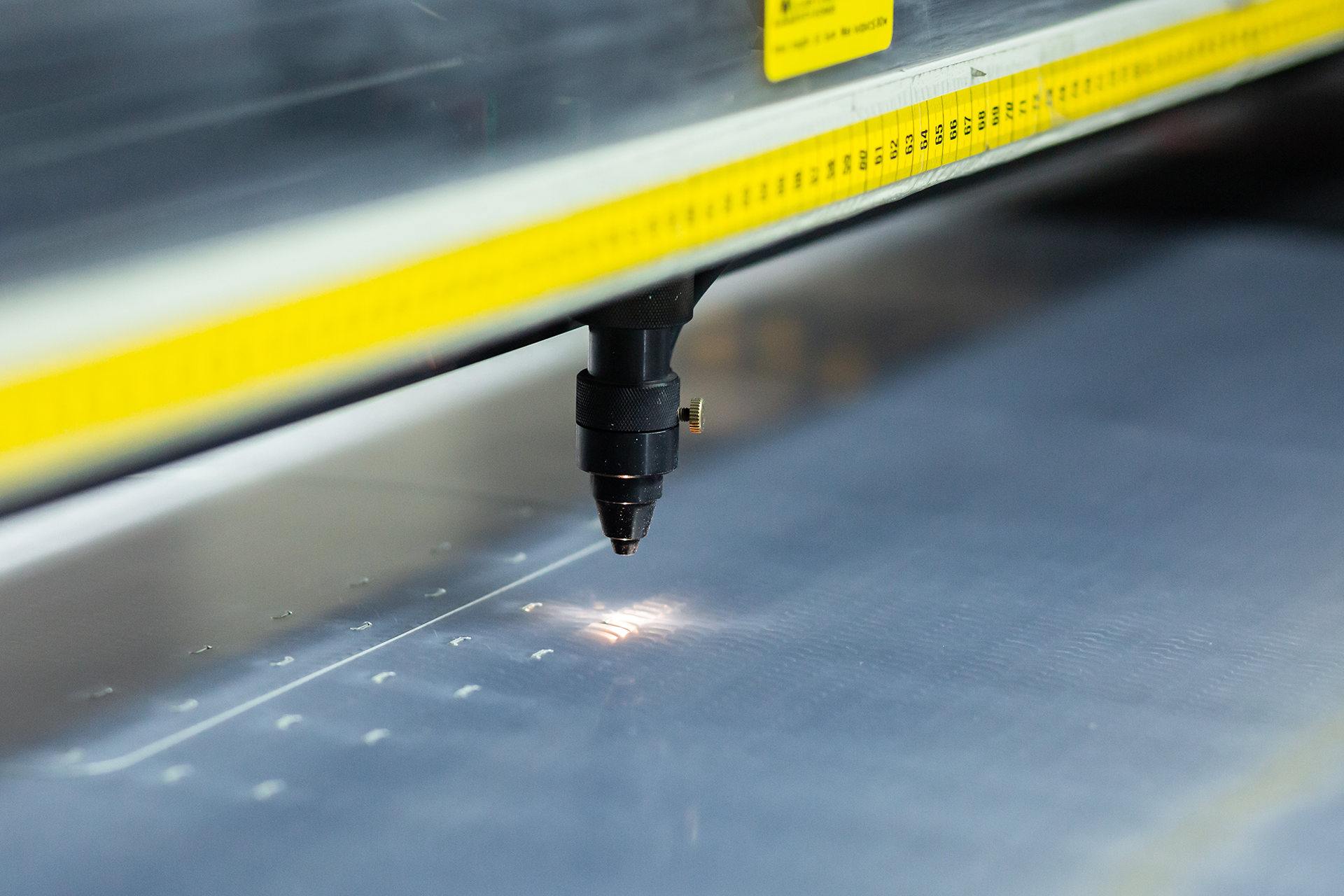

5. Material Uniformity and Fabrication Compatibility

Design consistency is crucial for architectural projects, especially when working across multiple fixtures or surfaces. Polished stainless offers uniform appearance, and unlike coated materials, doesn’t suffer from flaking or color inconsistency.

From a fabrication standpoint, it’s also easier to:

- Cut and bend without surface chipping

- Weld and polish seams to a matching finish

- Install with minimal finishing required post-fabrication

Action Stainless supports custom polishing, shearing, sawing, and cutting, helping fabricators reduce waste and keep project timelines tight. Our facilities are equipped to deliver large or small runs of polished stainless with consistent quality.

Applications in Architectural Settings

While polished stainless steel is most visible in high-end kitchens or luxury retail spaces, its utility spans across industries and use cases. Common applications include:

- Elevator interiors and doors

- Column wraps and wall panels

- Kitchen backsplashes and hoods

- Door frames and trim

- Lobby signage or reception desks

- Handrails and guardrails

Whether your design calls for high reflectivity or a uniform brushed finish, Action Stainless has the inventory and processing capability to deliver performance-grade materials to your specification.

Why Fabricators and Architects Choose Action Stainless

When specifying polished stainless steel, architectural teams count on more than just material availability, they need reliability, surface consistency, and responsive service. Action Stainless supplies:

- A wide selection of 304, 316, and specialty grades

- In-house polishing, cutting, and sourcing

- Fast lead times for custom and standard orders

- Regional distribution centers for reduced freight costs

From commercial hospitality projects to medical interiors, we’ve supported hundreds of fabricators and architects with polished stainless steel materials that meet their functional and visual goals.

Polished Stainless Steel: Where Strength Meets Style

Designing for function no longer means sacrificing visual impact. Polished stainless steel offers a smart, durable solution for architects, engineers, and fabricators working in demanding environments. With the right alloy, finish, and supplier, projects stay on schedule and look great doing it.

Action Stainless is your partner for high-performance architectural stainless steel. Reach out to discuss finish options, stock availability, or processing needs.