Material Testing and Certification: Ensuring Compliance in Industrial Projects

In today's industrial landscape, certified materials aren’t a luxury, they're a requirement. Whether you're supplying stainless steel for a food-grade processing system, a pressure vessel in an oil & gas facility, or a component in a chemical tank, traceable, tested, and certified metal is often required by code, client specifications, or insurance standards.

At Action Stainless, we recognize the critical importance of material testing and certification in stainless steel and aluminum distribution. That’s why we maintain rigorous documentation, traceability, and in-house inspection processes to support customers across demanding industries.

What Is Material Certification?

Material certification is the process of verifying that a metal product meets specific chemical and mechanical standards set by organizations such as ASTM, ASME, or ISO. These certifications include mill test reports (MTRs), certificates of conformance (COCs), and third-party test results when required.

Certified materials provide:

- Traceability to the original mill heat

- Chemical composition data for alloy integrity

- Mechanical properties like tensile strength or yield

- Compliance with ASTM, ASME, or FDA standards

- Documentation for client or regulatory audits

Action Stainless ensures that all material certifications are accurate, accessible, and

matched to the physical metal you receive.

Types of Material Tests Common in Stainless Distribution

Different projects demand different tests. Here’s how they apply in the stainless steel and aluminum distribution world:

| Test Type | Purpose | Common Applications |

|---|---|---|

| Positive Material ID (PMI) | Verifies alloy grade via spectrometer | Confirms grade of incoming/outgoing inventory |

| Mechanical Testing | Measures tensile strength, elongation, hardness | Pressure vessels, structural supports |

| Chemical Analysis | Confirms elemental breakdown (Cr, Ni, Mo, etc.) | Validates corrosion resistance for 304/316/2205 |

| Ultrasonic Testing (UT) | Detects internal flaws/nonconformities | High-pressure or safety-critical fabrications |

| Hardness Testing | Assesses surface durability | Wear-resistant or impact-prone components |

At Action Stainless, we handle

basic test validation in-house and can coordinate third-party testing and documentation when required without pushing it to an external supplier.

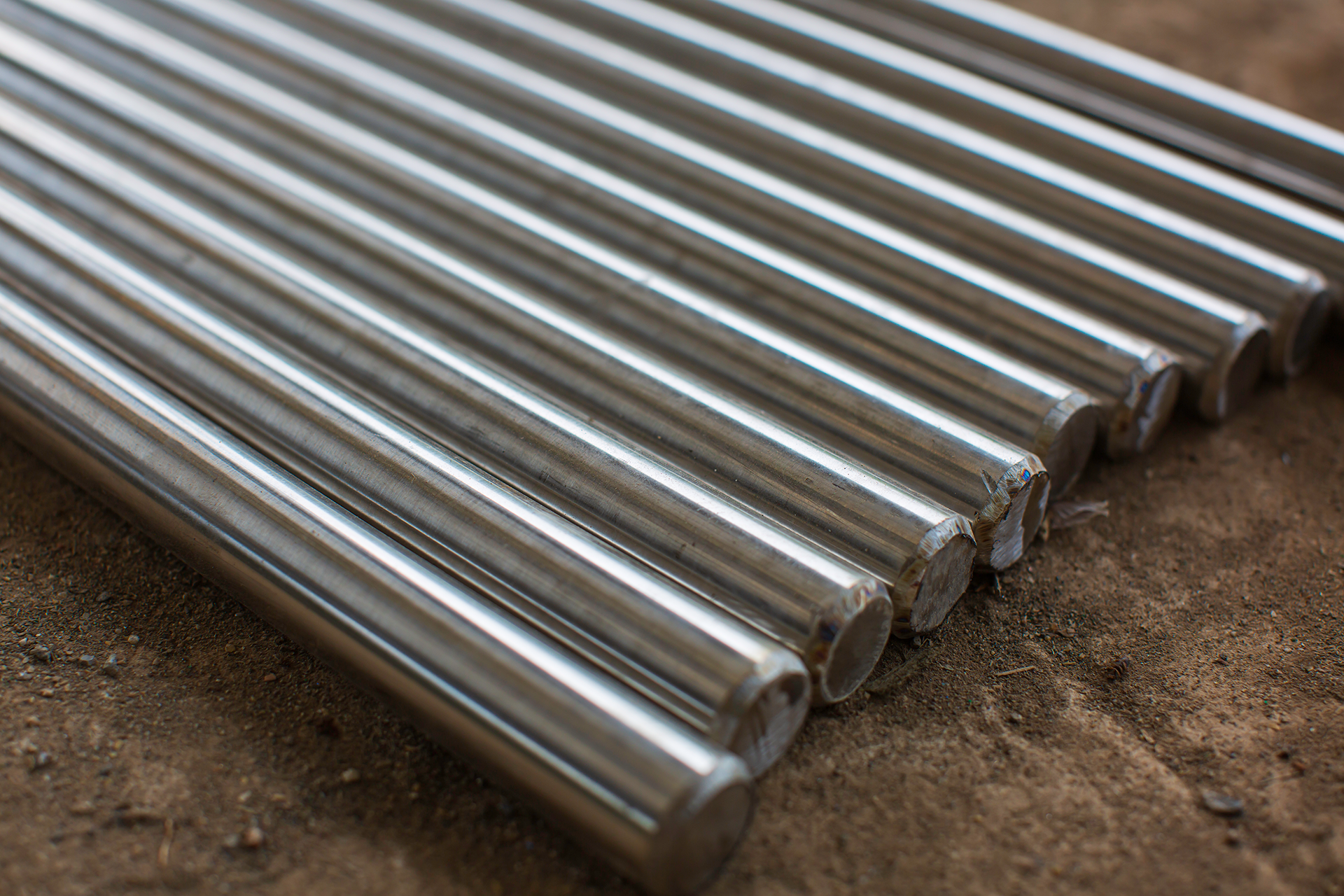

Certified Stainless Steel from Action Stainless

Not all stainless steel is created equal even if two plates are labeled “316L.” True performance depends on chemistry consistency, mill integrity, and lot traceability. We only source from approved mills and verify incoming material before distribution. Our in-house capabilities ensure that you receive the exact material grade, condition, and finish you specify.

We supply certified material across:

Each product ships with

heat number traceability and certification stored and retrievable for all prior orders.

Common Certifications Provided

Action Stainless routinely provides the following certification types:

Mill Test Reports (MTRs)

These documents from the producing mill show

chemical composition and mechanical properties. Each is matched to a

unique heat number and retained in our internal system for reference.

Certificate of Conformance (COC)

If requested, we can issue a document confirming that the material

meets your exact purchase specifications, such as dimensions, grade, finish, and tolerance.

FDA or NSF Compliance Letters

For food and pharmaceutical-grade applications, we support your compliance by ensuring

material traceability to standards appropriate for sanitary design.

Serving Regulated & High-Compliance Industries

We support companies that cannot risk uncertain materials. From chemical processors to tank fabricators, many of our customers require precise certification support, including:

- Pressure-rated vessels

- Sanitary process piping

- OEM components for food processing

- Cleanroom or medical-grade assemblies

- Heat exchangers and reaction tanks

These projects often require full traceability not just of the base material, but also of surface finish, cutting method, and value-added processing.

Certification Tied to In-House Services

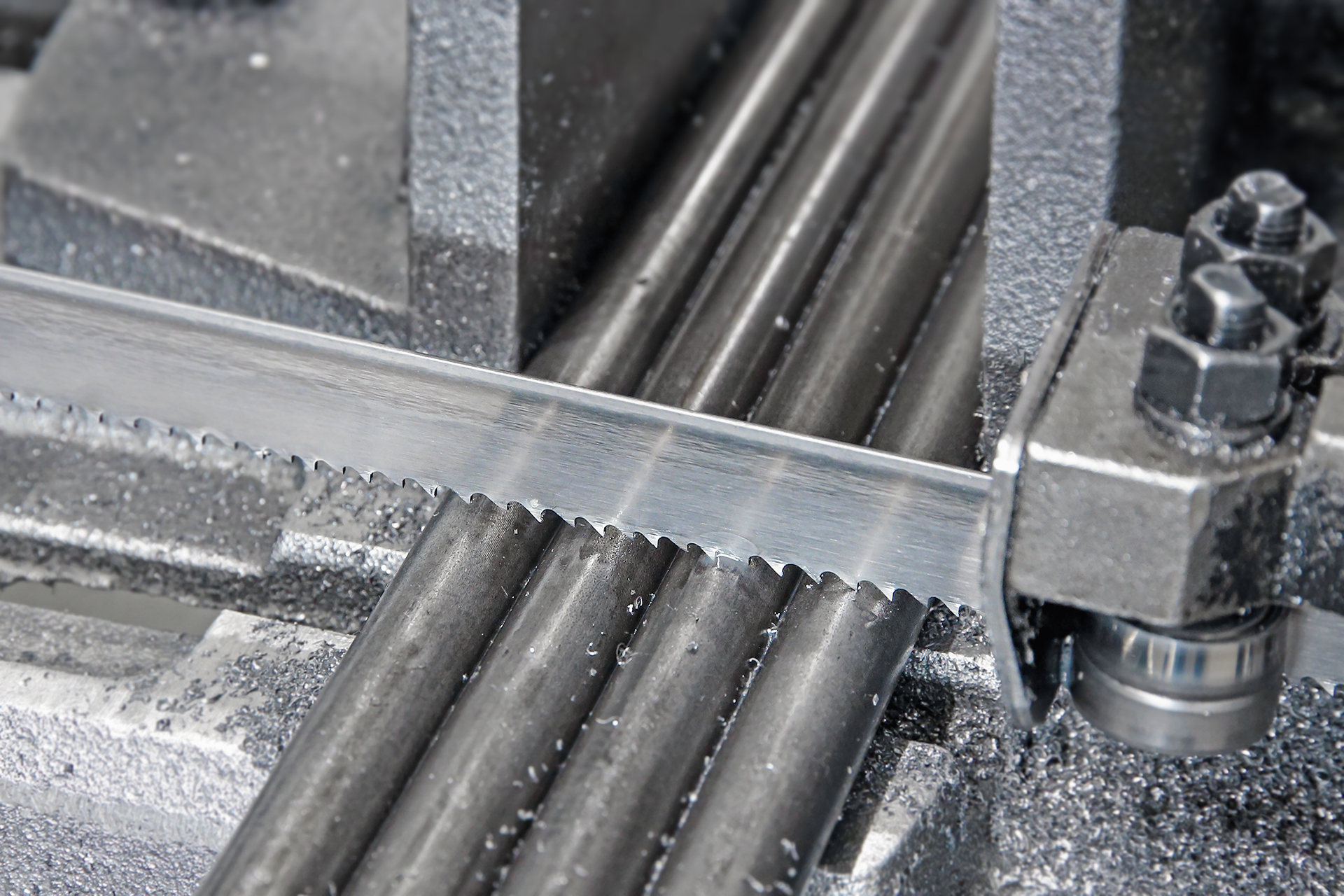

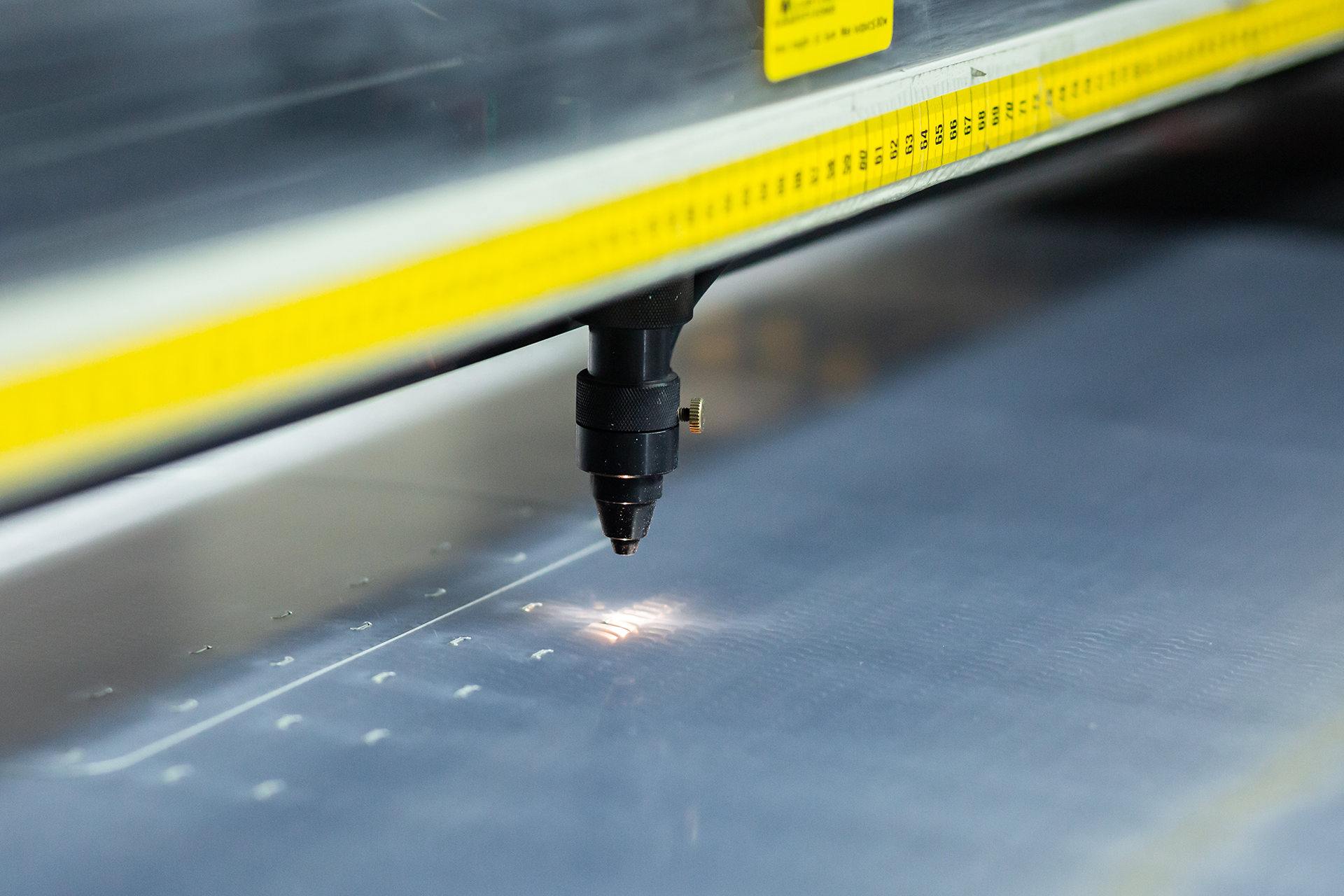

At Action Stainless, all cutting, grinding, and finishing are handled in-house, so certifications can include post-processing steps without needing additional vendors. This provides tighter control and documentation for services like:

- Saw cutting – We can note when and how your material was cut

- Grinding or polishing – Finish levels and surface prep are included in your record

- Precision tolerancing – Verified and recorded per your job specs

Because these services are never outsourced, you get

a direct line between your PO and your final certification documents.

What Happens If Certification Is Missing or Incomplete?

Failing to provide complete documentation can result in:

- Project delays due to rejected material at the jobsite

- Loss of customer trust or penalties in regulated markets

- Inability to pass audits for ISO or ASME compliance

- Costly rework or remanufacturing

That’s why Action Stainless maintains strict internal controls and a trained team that understands

both material specs and documentation standards.

Why Choose Action Stainless for Certified Metals?

We’re not just a distributor, we’re a service partner. Buyers across North America rely on us because we offer:

- Certified Stainless and Aluminum - with full traceability and documentation

- In-House Material Testing - including PMI and mechanical property checks

- On-Demand Certification - stored by heat number for customer reference

- Value-Added Processing - saw cutting, grinding, polishing, and more all traceable

- Responsive Service Team - real people who understand project timelines and compliance needs

Whether you’re building a structural assembly or supplying stainless to a regulated facility, we’ll help you stay compliant -

with no gaps, no outsourcing, and no guesswork.

Final Thought: Certified Quality, Delivered With Confidence

Material certification isn’t about paperwork, it’s about trust, performance, and accountability. The integrity of your final product often begins with the integrity of the raw metal you use.

At Action Stainless, certified metal is the standard, not an add-on. Every product is backed by real documentation, internal verification, and a customer-first approach to compliance.

FAQ: Stainless Steel Testing & Certification Services

What’s included in a standard mill test report (MTR)?

Each MTR includes chemical composition, mechanical properties, heat number, and the producing mill's stamp tied to the exact piece you receive.

Can Action Stainless coordinate third-party testing?

Yes. We frequently manage third-party UT, PMI, or mechanical testing for high-compliance projects, including ASME vessel builds.

Do you keep certification records on file?

We archive MTRs and certificates for traceability. If you need past documentation, our team can retrieve it quickly.

Are your cutting and grinding services certifiable?

Absolutely. Since they’re done in-house, we can include saw cutting, grinding, and polishing in your certification package.

What standards do your materials meet?

We regularly provide materials that meet ASTM, ASME, FDA, and NSF standards based on project needs and client specs.