Flat Bar, Round Bar, or Square? How to Choose the Right Stainless Bar Shape for Fabrication

Stainless steel bars are a fundamental component in fabrication, machining, and structural applications across industries. From commercial food equipment and oil & gas skids to structural supports and OEM parts, stainless bar stock delivers strength, corrosion resistance, and formability where it counts.

But selecting the right bar shape flat, round, or square can significantly impact cost, efficiency, and performance. Each form is engineered for specific types of loads, movement, or machining processes. Understanding how these shapes behave under stress, how easily they can be fabricated, and where they’re typically used helps engineers and purchasing managers avoid delays and downstream rework.

At Action Stainless, we stock flat bar, round bar, and square bar in multiple grades and sizes, supporting cut-to-length orders and in-house processing for fast, fabrication-ready delivery. Here’s how to determine which stainless bar shape fits your next job.

Understanding the Role of Bar Shape in Fabrication

Bar shape affects how metal performs when it's cut, bent, welded, or placed under load. While material grade and finish matter, the geometric form contributes just as much to structural support, alignment, and manufacturability.

- Choosing the wrong bar profile can lead to:

- Poor load-bearing capacity

- Excessive scrap from incompatible cuts

- Difficulties in fixturing or jig alignment

- Added costs due to rework or reshaping

To make the right selection, it’s essential to match the shape to both design requirements and fabrication capabilities.

Comparing Stainless Bar Shapes

The table below highlights key differences among flat, round, and square stainless bars commonly used in fabrication and structural work:

| Feature | Flat Bar | Round Bar | Square Bar |

|---|---|---|---|

| Shape Profile | Rectangular cross-section | Circular cross-section | Square cross-section |

| Common Uses | Bracing, structural components, brackets, cabinetry | Shafts, pins, fasteners, CNC parts | Frames, supports, handrails, general fabrication |

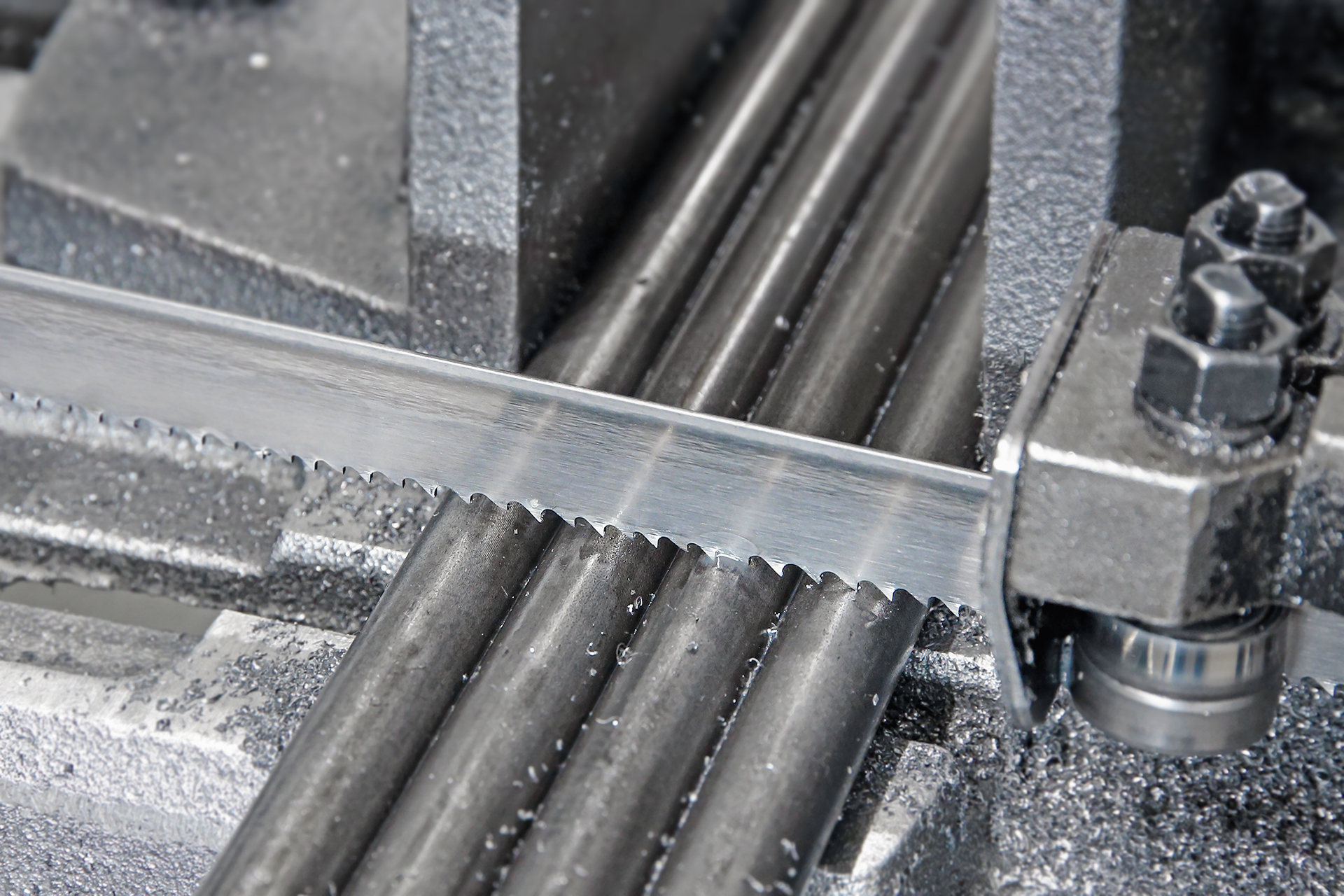

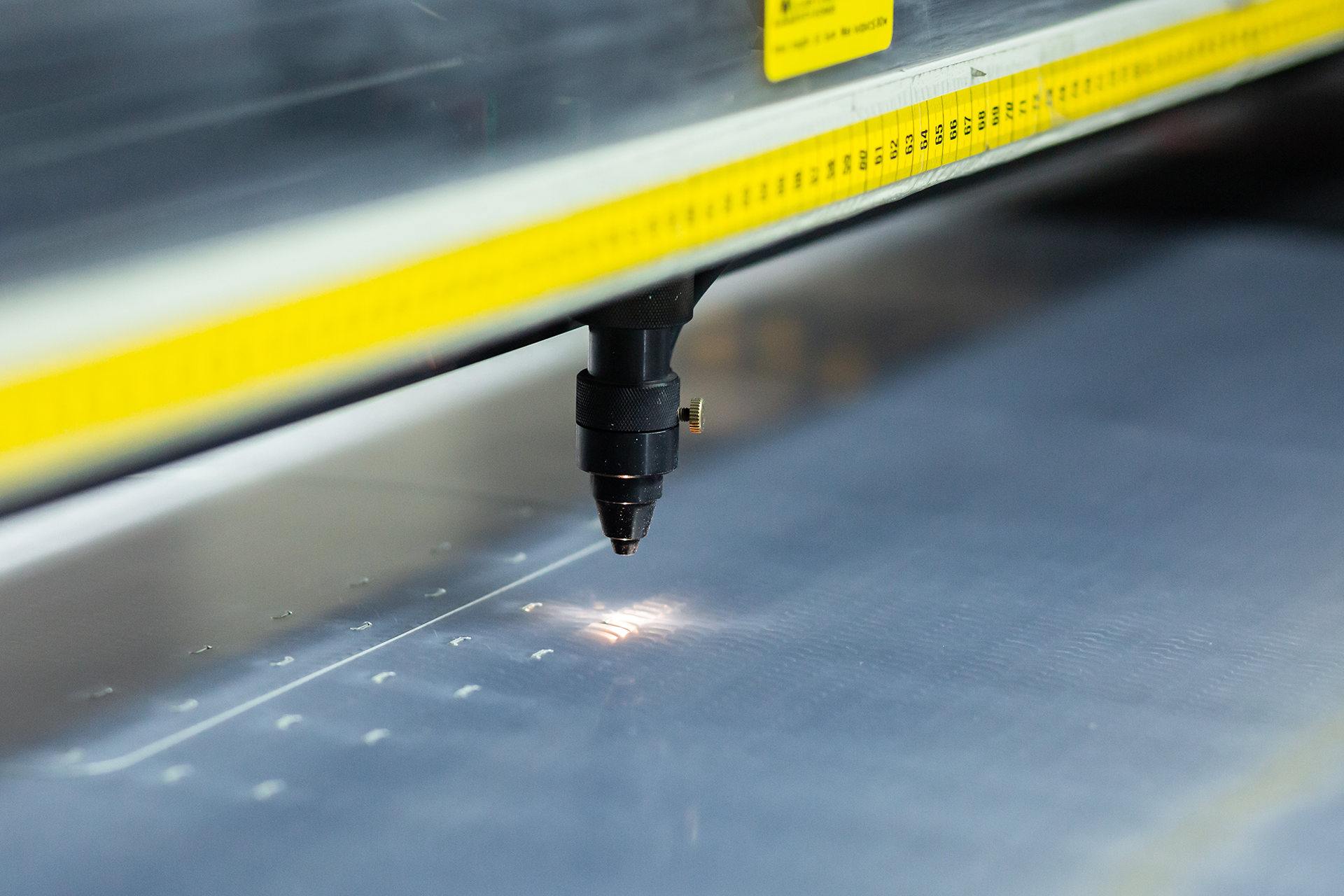

| Machinability | High surface area; good for cutting, drilling | Ideal for turning, threading, and CNC lathing | Easily fixtured for precise cutting and tapping |

| Load Distribution | Strong in one direction (flat face) | Uniform load in all directions | Balanced support on both X and Y axes |

| Flexibility/Formability | Easy to bend across width; stiff across thickness | Uniform flex; suitable for torsion and bending | Moderate formability; stiffer than flat bar |

| Applications at Action Stainless | Custom brackets, trim, structural supports | Shafts, pins, machined parts for OEM and energy sectors | Handrails, square tubing fillers, custom framework |

When to Use Flat Bar

Flat stainless bar is one of the most versatile shapes available. With a rectangular profile and wide face, it excels in applications where rigidity is needed in one direction ideal for reinforcement, bracing, or support.

Applications:

- Framing in food equipment or marine assemblies

- Architectural trim and bracketing

- Baseplates or stiffeners in fabrication frames

- Custom conveyor guides or rails

Flat bars are also easier to weld and polish due to their open face, making them a common pick in aesthetic or sanitary environments.

At Action Stainless, we supply flat bars in 304, 316, and 303 stainless, with saw-cutting and surface polishing services available for precise fit and finish. Whether for structural assembly or sanitary process use, we help match thickness and width to your load specs.

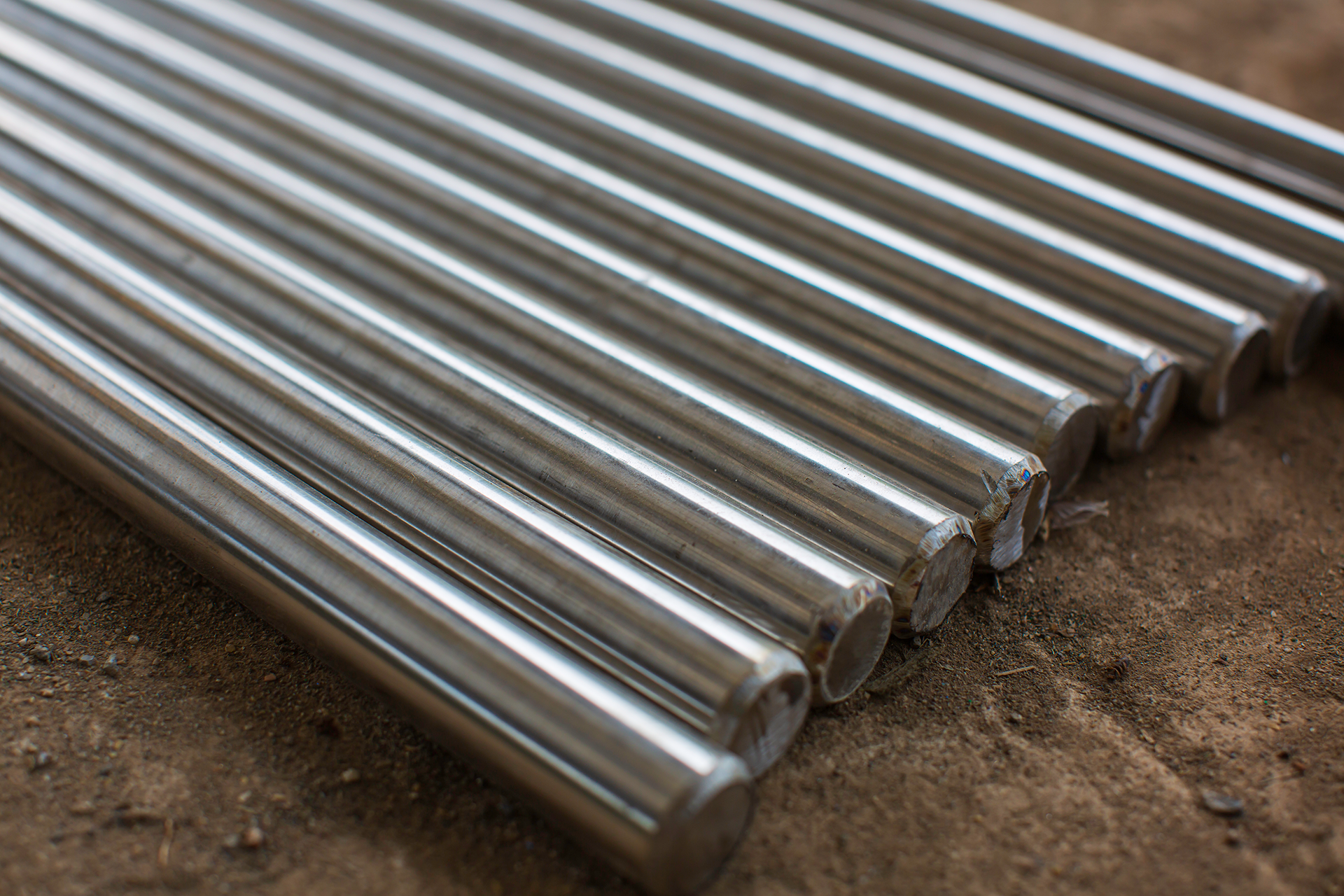

When to Use Round Bar

Round stainless bar is ideal for rotating parts or applications that require machining symmetry. Its even geometry distributes loads evenly in all directions and is easily spun, turned, or threaded.

Industries that use round bar:

- Automotive and off-road components

- Oil & gas and energy parts

- Shafts, rods, and alignment pins in OEM manufacturing

Fabricators often select 303 or 416 stainless round bar for its superior machinability. For corrosion resistance, 304 and 316 grades are standard. Round bar’s versatility in CNC and manual lathes makes it a go-to for custom machining operations where consistent dimensional tolerance is critical.

Action Stainless offers round bar in multiple diameters and lengths, including full bar and custom cut-to-length, with chamfering available to meet print specs or reduce handling risk.

When to Use Square Bar

Square stainless bar provides uniform strength along both X and Y axes, making it a solid choice for frameworks, supports, and grid-type structures. Its 90-degree edges make it easy to fixture and align, which benefits multi-bar fabrication and welding.

Typical applications:

- Rigid frames in food processing or manufacturing lines

- Architectural grates or design features

- Support posts, trim, and grid sections

Square bar is also used as a structural spacer or transition piece when round tubing or rectangular frames aren’t suitable. Its clean edge profile provides a crisp visual line, often valued in architectural and design projects.

Action Stainless carries square bars in 304 and 316 stainless, with available polishing for use in aesthetic or sanitary-grade environments. Our in-house saw cutting enables square bar precision tailored to layout and weld spacing.

Stainless Grades and Finishes Available

Each stainless bar shape is available in multiple grades to meet varying corrosion, strength, and machinability requirements:

- 304 Stainless – General-purpose corrosion resistance

- 316 Stainless – Superior corrosion resistance (chloride, food-grade)

- 303/416 Stainless – Optimized for machining applications

At Action Stainless, we also provide bar finishes suitable for sanitary or aesthetic projects, including:

- HRAP (Hot Rolled Annealed & Pickled)

- Cold Drawn

- Polished (180 grit, 240 grit, etc.)

Whether the job calls for rough framing or polished railings, we match the bar shape and finish to the use environment.

How Action Stainless Supports Fabricators

Choosing the right stainless bar shape starts with understanding how the product will be fabricated and installed. At Action Stainless, our in-house services streamline the process with:

- Saw cutting to your spec length

- Polishing for architectural or sanitary applications

- Custom sourcing of uncommon bar sizes or finishes

- Local stocking to reduce project lead times

We support fabricators across industries from custom machine shops to stainless kitchen fabricators delivering quality bar stock on time and ready for the next stage.

Final Considerations: Matching Shape to Performance

While material grade defines chemical resistance and strength, bar shape determines form, fit, and fabrication outcome. Here are final considerations when comparing flat, round, and square bar stock:

- Flat bar is ideal for bracing, trim, or plate-style fabrication

- Round bar is best for rotational, machined, or load-spread parts

- Square bar is preferred for clean lines, even load distribution, and framework

Selecting the right bar shape minimizes waste, improves assembly alignment, and simplifies finishing.

Optimize Your Fabrication Workflow with Action Stainless

If you're designing a component, building custom frames, or replacing bar stock in existing machinery, choosing the right stainless shape can save time and increase performance. Action Stainless delivers flat, round, and square bars cut, polished, and ready for fabrication backed by technical support and fast regional delivery.