What to Consider When Specifying Stainless Steel for Tank Fabrication

Stainless steel continues to be the go-to material for tank fabrication in food, beverage, pharmaceutical, and chemical processing industries. Its corrosion resistance, hygienic surface properties, and ability to withstand extreme temperatures and pressures make it a strong choice for demanding environments. But not all stainless steel is the same, and selecting the right grade and form is critical to ensuring tank durability, cleanability, and long-term performance.

At Action Stainless, we work directly with manufacturers, fabricators, and process engineers to supply the stainless material solutions that fit each tank project. Whether you're designing tanks for dairy processing, chemical storage, or brewery operations, understanding the differences between grades, finishes, and fabrication compatibility can help avoid costly errors.

Key Factors When Selecting Stainless for Tanks

Choosing the correct stainless steel goes beyond corrosion resistance. Here are the core areas every specifier should evaluate:

1. Corrosion Resistance and Application Environment

Stainless steel's ability to resist corrosion varies by grade. For tanks used in chemical processing or food-grade environments, resistance to acids, salts, and cleaning agents is critical. 304 and 316 stainless steels are the most commonly used due to their balance of cost and corrosion performance, but the selection depends on what's stored and how the tank is cleaned.

2. Weldability and Fabrication Compatibility

Not all stainless steels weld the same way. For large storage tanks, field welding and fabrication efficiency can impact both timelines and cost. Grades with excellent weldability and post-weld corrosion resistance like 304L or 316L are typically favored.

3. Mechanical Properties and Strength Requirements

Tanks storing pressurized or heated materials require alloys that maintain strength under thermal expansion. Thickness, weight, and structural loading should be evaluated in relation to the grade’s mechanical capabilities.

4. Surface Finish and Cleanability

For sanitary tanks, smoother finishes are necessary to reduce bacterial buildup and simplify cleaning. A polished or passivated surface improves corrosion resistance and meets FDA or 3A standards in food and pharma applications.

5. Cost and Material Availability

Budget constraints may influence the grade or form chosen. At Action Stainless, we stock a wide variety of stainless plate, sheet, bar, and tubing options that allow fabricators to meet both design and budget requirements without compromising performance.

Comparing Common Stainless Grades for Tanks

Below is a comparison of the most commonly specified stainless steel grades used in tank fabrication:

| Property | 304/304L | 316/316L | 2205 Duplex |

|---|---|---|---|

| Corrosion Resistance | Good | Excellent (chloride/acid resistant) | Excellent (pitting/crevice resistant) |

| Weldability | Excellent | Excellent | Good (may require preheat/post-weld care) |

| Cost | Lower | Higher | Higher |

| Typical Use Cases | Food storage, dairy, water tanks | Brewery, pharma, saltwater exposure | Chemical, high-pressure tanks |

| Finish Options | 2B, No. 4, polished | 2B, No. 4, polished | Mill, custom finishes |

Each grade presents advantages depending on the environment and cleaning agents involved. For example, 316 is often preferred in breweries or saltwater-exposed tanks, while duplex steels are reserved for tanks under pressure or containing aggressive chemicals.

Design Considerations in Tank Fabrication

Once the stainless grade is selected, several other factors influence how the tank will perform under operational conditions:

Thermal Expansion and Contraction

Tank walls and welds expand and contract with temperature swings. Stainless steel has relatively high thermal expansion, especially in hot CIP (clean-in-place) systems. Material thickness and reinforcement may need to be adjusted to prevent deformation over time.

Weld Seams and Heat-Affected Zones

Proper heat input and shielding during welding are essential to avoid sensitization and weakening of the grain structure. Post-weld passivation or pickling is often recommended to restore corrosion resistance in the weld zone.

Drainage and Slope Design

Tanks in sanitary applications must allow for complete drainage. Internal welds and slopes should be smooth, continuous, and self-draining to avoid bacterial buildup.

Finish Treatments and Passivation

After welding and fabrication, passivation can be applied to remove iron particles and promote a uniform oxide layer. This step enhances corrosion resistance and is often specified for food, beverage, and pharmaceutical tanks.

Regulatory and Compliance Standards

In certain industries, tank design must comply with ASME, FDA, USDA, or 3A standards. These often specify allowable surface finishes, testing requirements, and documentation. Choosing the appropriate grade and finish ensures easier path to certification.

Why Fabricators Choose Action Stainless

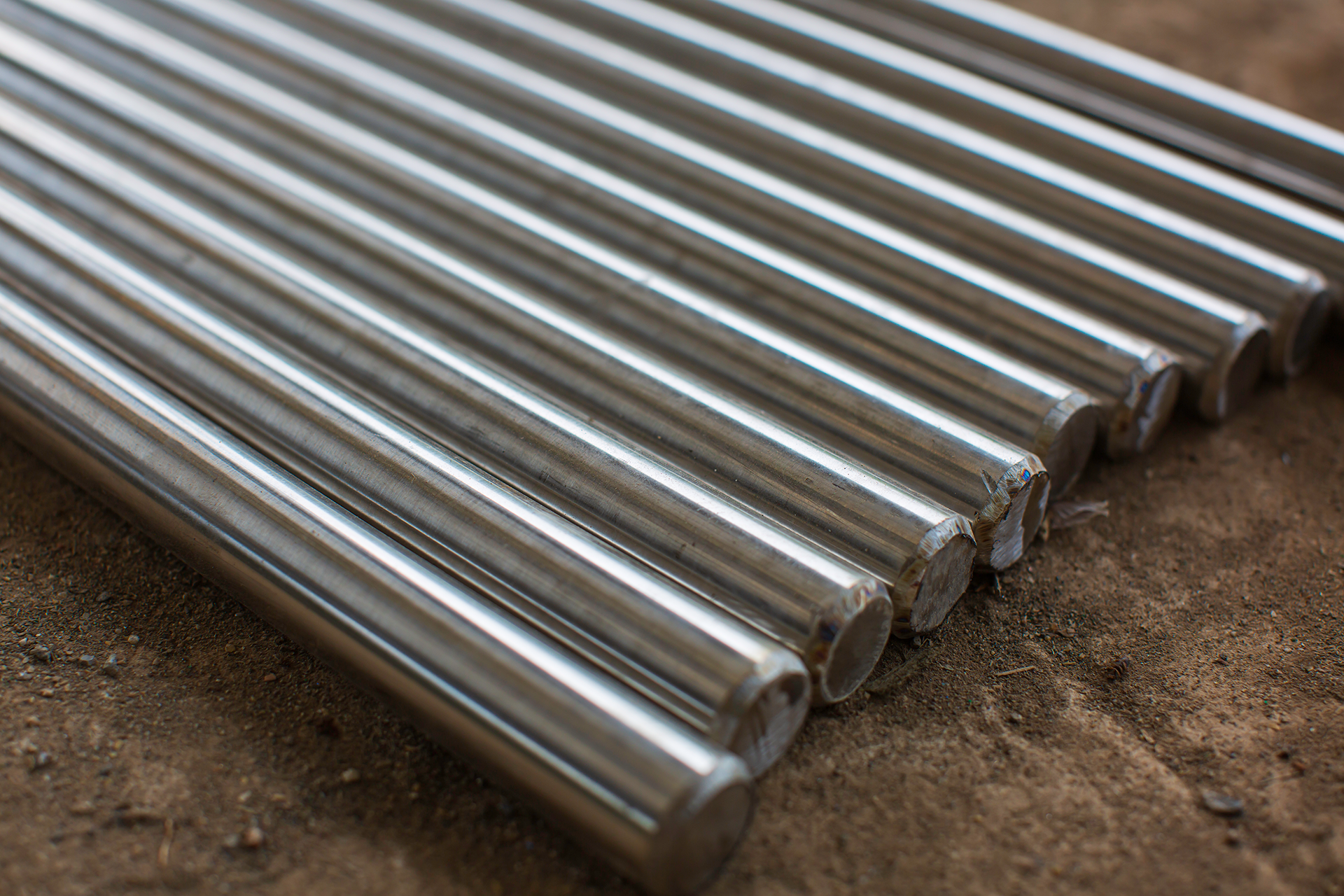

At Action Stainless, we supply more than just material we help solve fabrication challenges. Our inventory includes stainless sheet, plate, structural tubing, and bar in grades 304, 304L, 316L, 2205, and more. We offer:

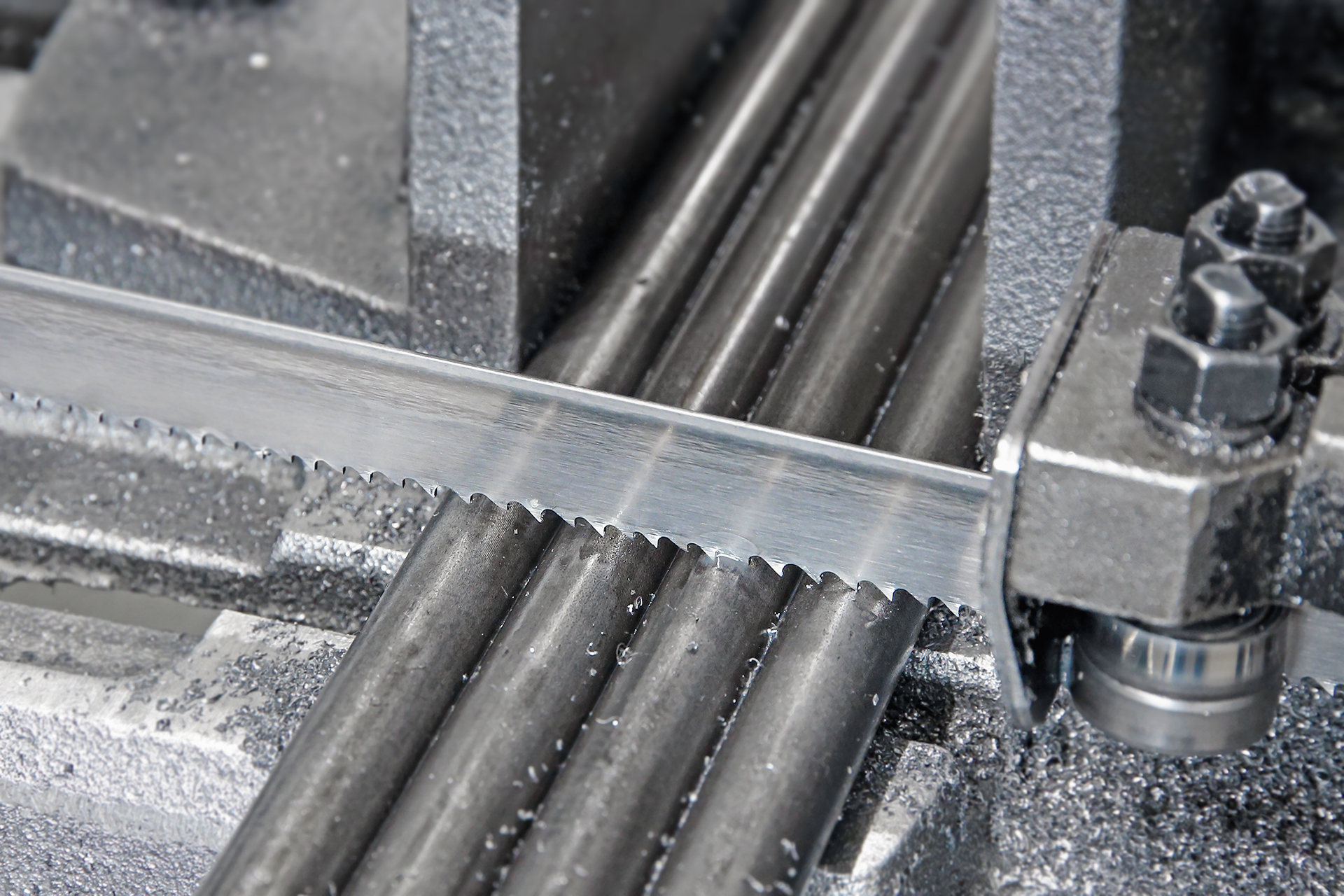

- Cut-to-length capabilities for large plate and bar

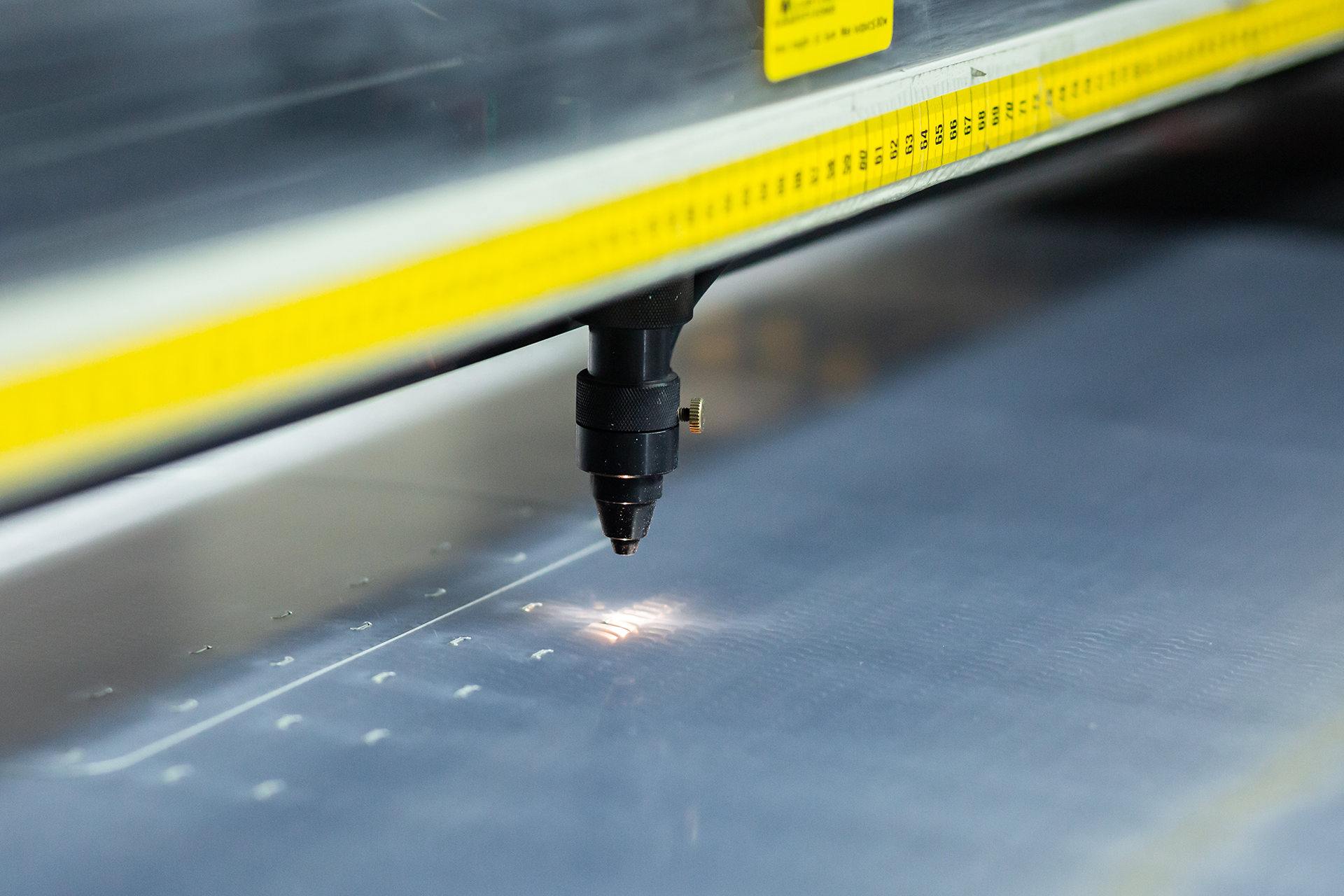

- Saw cutting, plasma, laser, and waterjet options

- Consistent quality with traceable mill certifications

- Fast delivery to support just-in-time fabrication

Our team understands the nuances of tank design and can assist in selecting the right material grade and form to meet your project goals.

When 304 Isn't Enough: Upgrading to 316 or Duplex

While 304 stainless is the default option for many tanks, there are use cases where upgrading to 316 or duplex stainless is the safer choice:

- High Chloride Environments: Salt-heavy ingredients, brine storage, or coastal installations can break down 304’s protective layer over time. 316L resists these effects.

- Aggressive CIP Chemicals: If caustic or acidic cleaners are used frequently, the added molybdenum in 316 increases protection.

- High Pressure Applications: Duplex stainless steel provides higher tensile strength and corrosion resistance, especially in chemical and oil & gas tanks.

While the upfront material cost may be higher, lifecycle savings from reduced maintenance and downtime can justify the upgrade.

Supporting Tank Builders with Precision Service

Action Stainless supports tank builders from concept to cut. Whether you need polished sheet for internal surfaces, structural bar for framing, or certified plate for pressurized vessels, we deliver quality material ready for fabrication. With an experienced team and coast-to-coast distribution network, we’re built to serve your tank-building timeline.

Inquire today about stainless grades, bar stock, or custom-cut services tailored to your tank project.