From Raw Material to Finished Part: The Journey of Precision-Cut Stainless and Aluminum

In the world of metal fabrication, precision isn’t optional, it’s essential. Whether you're building kitchen equipment, industrial enclosures, food processing lines, or architectural structures, the accuracy of every cut, edge, and surface finish matters. That’s where Action Stainless makes the difference, supporting fabricators and manufacturers from the raw stock stage to precisely prepped metal ready for production.

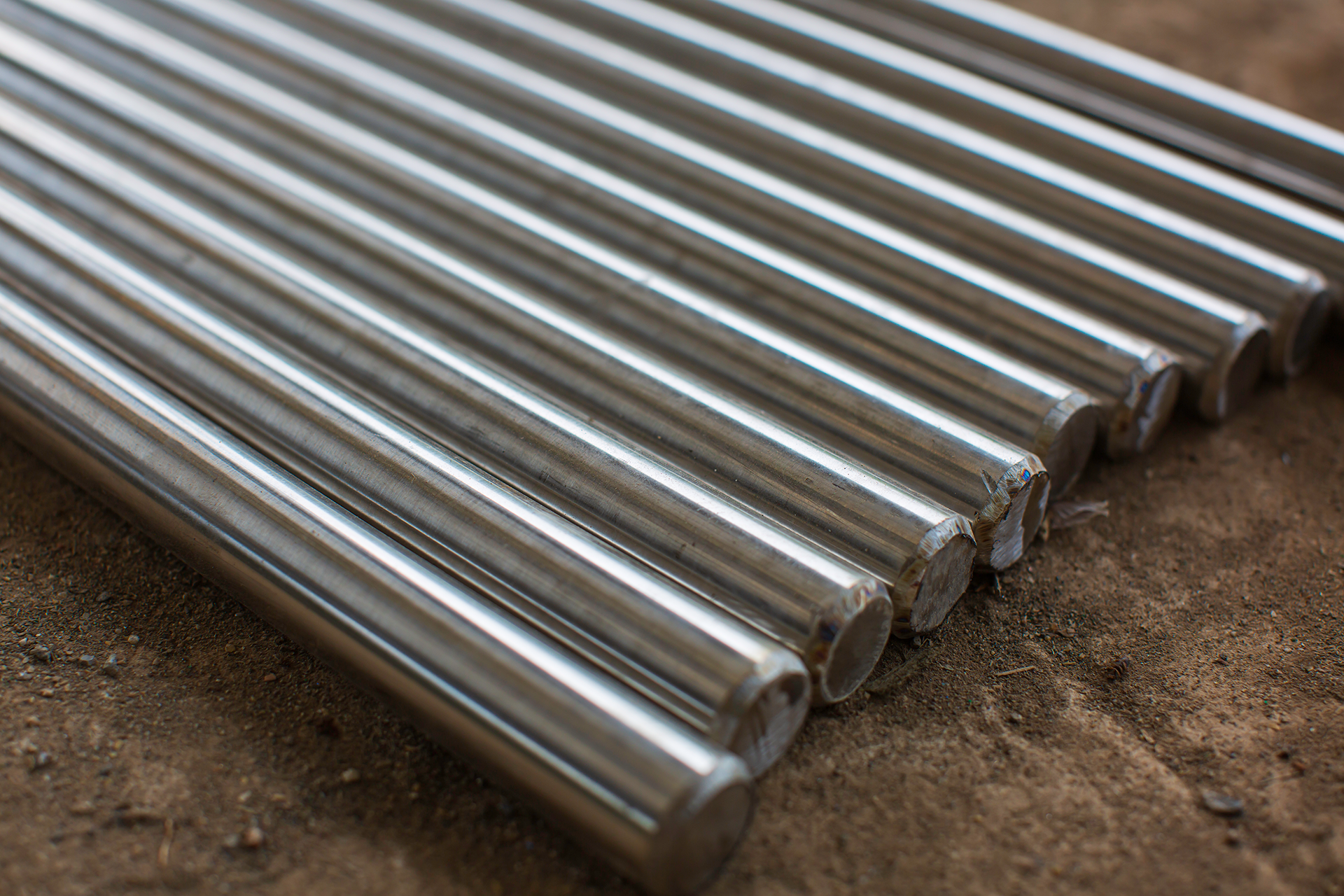

Material Sourcing: Stainless & Aluminum in Stock

Action Stainless maintains a robust inventory of both stainless steel and aluminum products, including sheet, plate, bar, and tubing. Common grades like 304, 316, and 430 stainless, as well as 5052 and 6061 aluminum, are stocked in a variety of thicknesses and sizes.

Clients can request mill-finish material or choose from brushed, polished, or coated finishes depending on the end-use. By offering a broad product line with same-day processing capabilities, Action Stainless ensures customers get the material they need without long lead times or excessive waste.

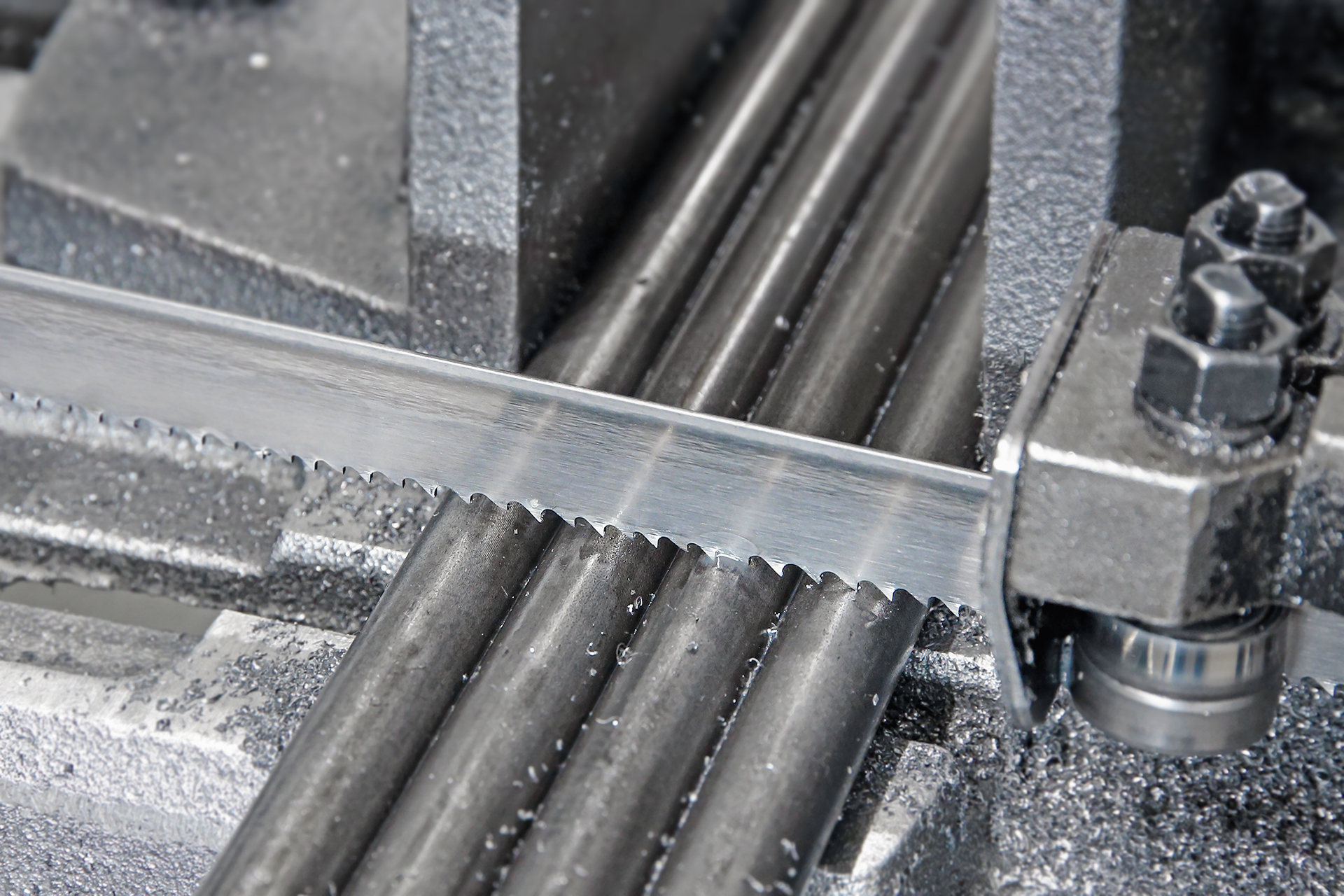

Shearing & Sawing: Precision at the First Cut

The journey from raw stock to functional part often begins with accurate shearing or sawing. Action Stainless uses high-capacity shears to cleanly cut flat stock with minimal burrs, and precision saws to handle bar and tube products with tight tolerances. Whether you're preparing blanks for fabrication or cutting aluminum bar for structural framing, accuracy at this stage saves both time and material.

These processes are not just about cutting metal they're about setting your project up for success. Tight tolerances, clean edges, and uniform sizing ensure that downstream processes like welding, forming, and assembly go smoothly.

Cutting Services Offered by Action Stainless

| Service | Material Type | Application |

|---|---|---|

| Shearing | Stainless sheet, aluminum sheet | Flat parts, panels, blanks |

| Band Saw Cutting | Stainless/aluminum bar & tube | Structural components, brackets |

| Plate Sawing | Thick stainless & aluminum plate | Heavy-duty frames, equipment bases |

| Miter Cutting | Aluminum extrusions, angle bar | Framing, architectural trims |

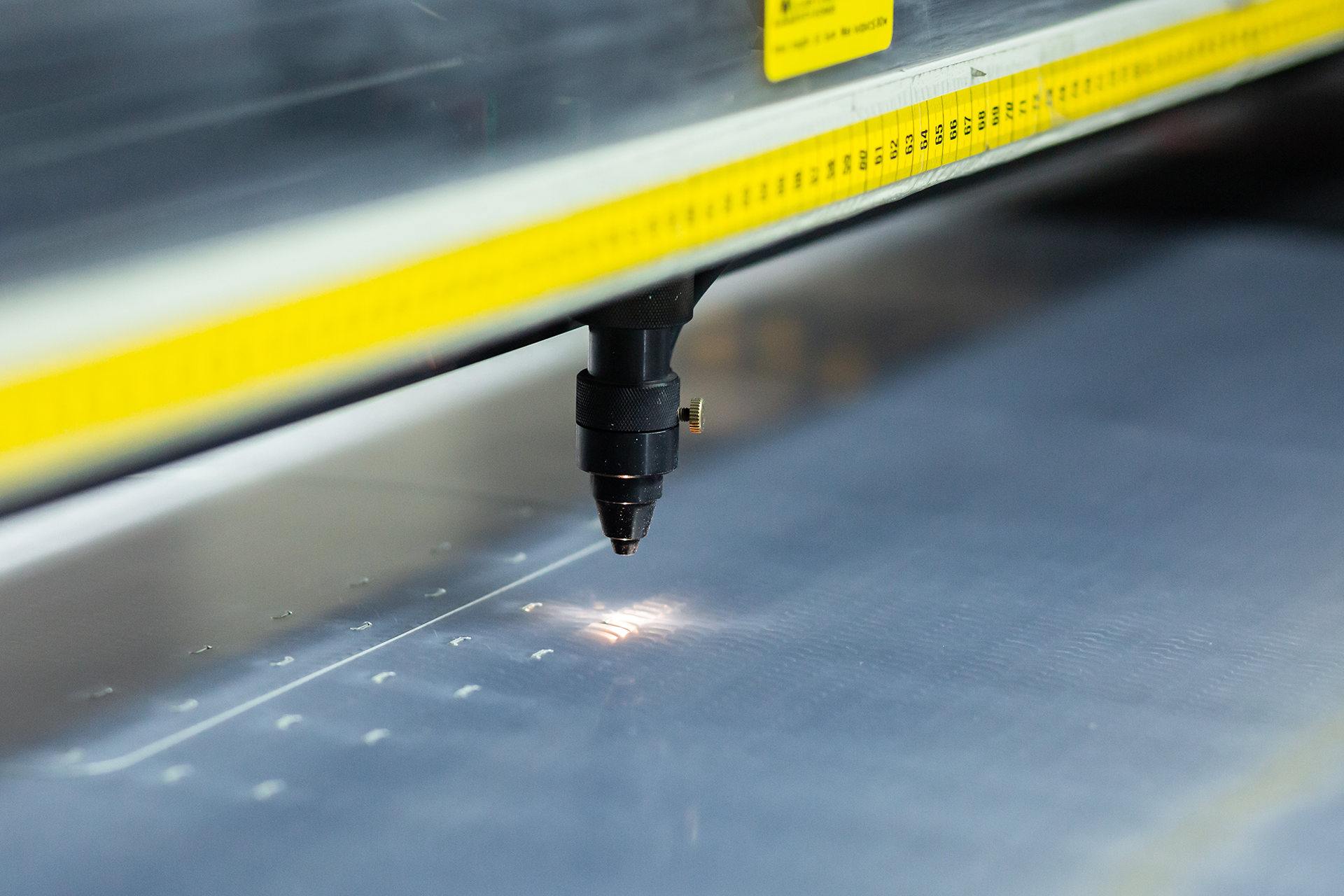

Clean, Accurate Cuts for OEMs and Fabricators

After shearing or sawing, many projects require additional shaping. Action Stainless supports this with plasma cutting, waterjet cutting, and laser cutting partners. This flexibility allows customers to move from raw sheet or bar to custom parts with precise features and tight tolerances all within a streamlined workflow.

This level of service is particularly important to OEMs and contract fabricators who rely on material partners to meet production timelines. With in-house cutting, Action Stainless minimizes lag between ordering and fabrication.

Deburring, Labeling, and Prep for Final Fabrication

Once parts are cut, they often require additional steps to be shop-ready. Action Stainless provides deburring and edge-finishing services that improve worker safety and reduce rework during fabrication. Custom labeling and kitting also simplify material handling and inventory management.

These added-value services make it easier for manufacturers to integrate materials into their production lines, saving labor hours and improving shop efficiency.

Real-World Example: From Coil to Commercial Panel

Consider a fabricator building stainless panels for a ventilation system. They order 304 sheet from Action Stainless, cut to length, deburred, and prepped with a brushed #4 finish. With materials arriving ready to form, the shop skips initial prep steps, bends the panels, welds the seams, and assembles the final unit within days.

This approach cuts down on internal labor and speeds up turnaround critical for jobs under tight deadlines or requiring code-compliant performance.

Why Partner With Action Stainless

Metal suppliers are easy to find but few offer the service-first mindset that defines Action Stainless. The ability to source, process, and deliver precision-cut material helps customers of all sizes reduce scrap, boost efficiency, and meet high standards of accuracy and finish.

From one-off jobs to ongoing OEM contracts, Action Stainless works with clients to deliver material that’s not just metal, but a ready-to-use solution.

Need precision-cut stainless or aluminum for your next build? Contact Action Stainless to streamline your process from raw material to finished part faster, cleaner, and more reliably.