Why 5052 Aluminum Is the Top Choice for Marine and Structural Fabrication

Aluminum continues to gain popularity in marine and structural fabrication due to its lightweight strength, corrosion resistance, and ease of fabrication. Among the available grades, 5052 aluminum stands out as a top performer in both durability and workability.

From boat hulls and railings to tank bodies and building facades, 5052 offers excellent resistance to saltwater and atmospheric corrosion while remaining easy to shape and weld. In this blog, we’ll explore the unique material properties of 5052 aluminum, how it compares to other grades like 3003 and 6061, and why it's become a top choice for industrial fabricators and manufacturers working in demanding environments.

The Material Profile of 5052 Aluminum

5052 is a non-heat-treatable aluminum alloy that contains magnesium as its primary alloying element. This composition delivers a strong balance of strength, corrosion resistance, and formability making it ideal for both structural frameworks and marine applications.

Key Properties of 5052 Aluminum:

- Excellent Corrosion Resistance – Particularly in saltwater and marine environments

- High Fatigue Strength – Resists cracking under cyclic loads

- Good Weldability – Works well with both TIG and MIG welding

- Strong Formability – Easily bent, rolled, or shaped without cracking

- Moderate Strength – Higher than 1100 and 3003, slightly lower than 6061 in tensile strength

These properties make 5052 a flexible and dependable option across a wide range of fabrication processes and end uses.

Why 5052 Excels in Marine Applications

Marine environments present constant challenges for metals due to salt, moisture, and exposure to varying temperatures. 5052 aluminum is naturally equipped to perform in these conditions without requiring extensive coatings or treatments.

- Saltwater Resistance: Unlike steel, which rusts rapidly, 5052 forms a natural aluminum oxide layer that protects it from further corrosion especially important for hulls, pontoons, and frames exposed to seawater.

- No Rusting or Pitting: 5052 resists the kind of pitting corrosion common in chlorinated or briny environments.

- Weight Advantage: It provides comparable performance to steel at a fraction of the weight, enabling more efficient boat and trailer designs.

From fishing vessels to recreational boats and walkways, this alloy keeps projects structurally sound while minimizing maintenance needs.

Why It Performs Well in Structural Fabrication

5052 is also widely used in architectural, transportation, and industrial applications thanks to its strength and workability. It can be used to create curved components, roll-formed panels, and various types of structural bracing and housings.

Benefits for Structural Fabricators:

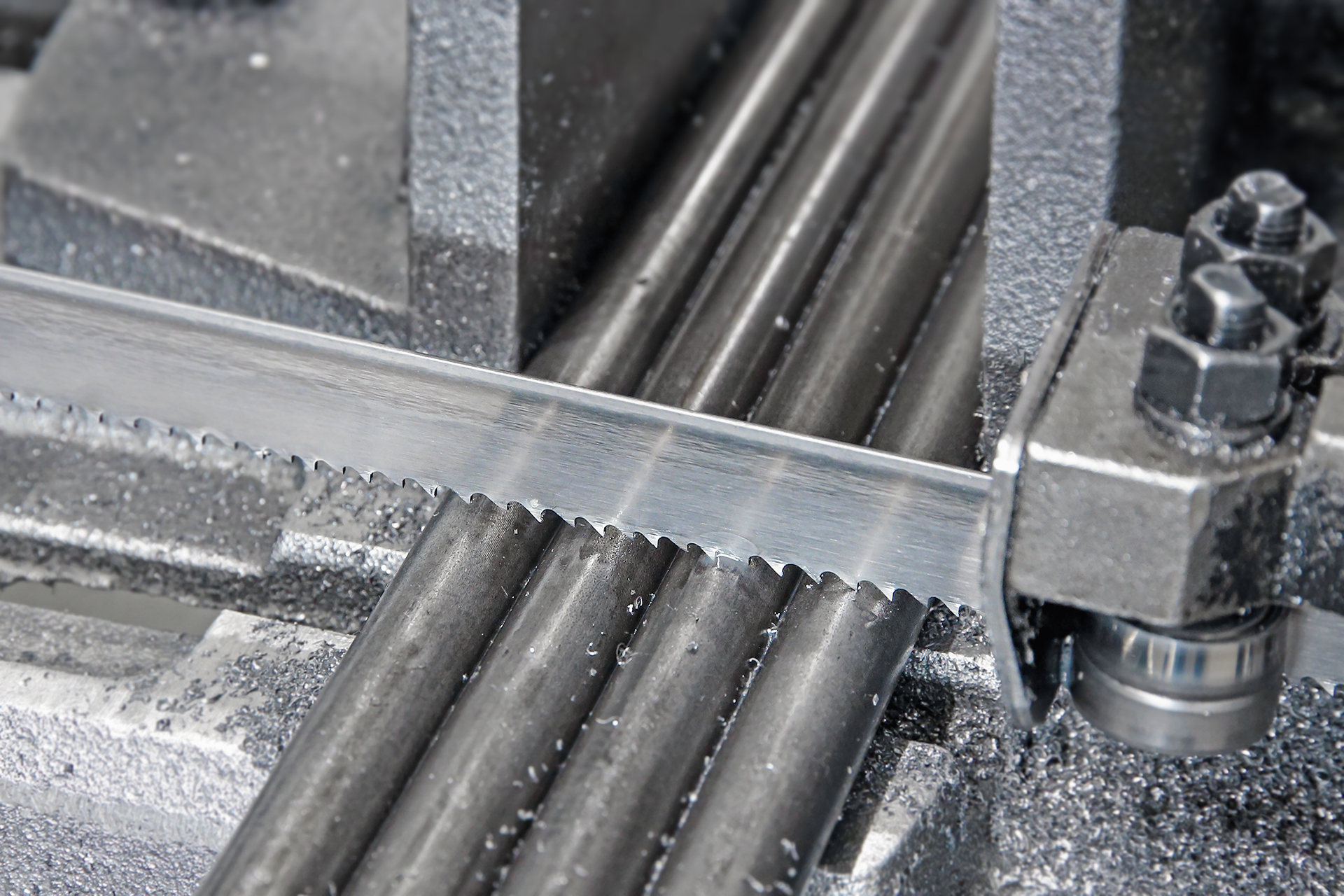

- Easily Cut and Welded: Responds well to saw cutting, CNC routing, MIG, and TIG welding.

- Bends Without Breaking: Ideal for press brake work, rolling, and shearing.

- Durable Finishes: Holds paint and anodizing well, making it suitable for visible architectural elements.

- Less Material Waste: Its ductility allows for tighter forming with fewer cracks or errors.

5052 also sees use in platforms, building facades, tanks, catwalks, and stair components anywhere that combines aesthetics with performance.

5052 vs. Other Common Aluminum Grades

Understanding how 5052 compares with other aluminum grades can help in choosing the right alloy for your specific fabrication needs.

| Property | 5052 Aluminum | 3003 Aluminum | 6061 Aluminum |

|---|---|---|---|

| Strength | Medium-High | Medium | High |

| Corrosion Resistance | Excellent | Good | Good |

| Weldability | Excellent | Excellent | Good |

| Formability | Excellent | Excellent | Fair |

| Machinability | Fair | Fair | Good |

| Heat Treatable | No | No | Yes |

| Common Uses | Marine, structural, tanks | Roofing, cookware, signage | Aerospace, frames, tools |

Summary:

- 5052 offers the best mix of strength and corrosion resistance for marine and light structural use.

- 3003 is better for light-duty, non-load-bearing applications.

- 6061 is stronger but less formable, ideal for aerospace or rigid frames.

Common Applications of 5052 Aluminum

5052 aluminum’s versatility shows in the broad range of industries that rely on it for both performance and manufacturability:

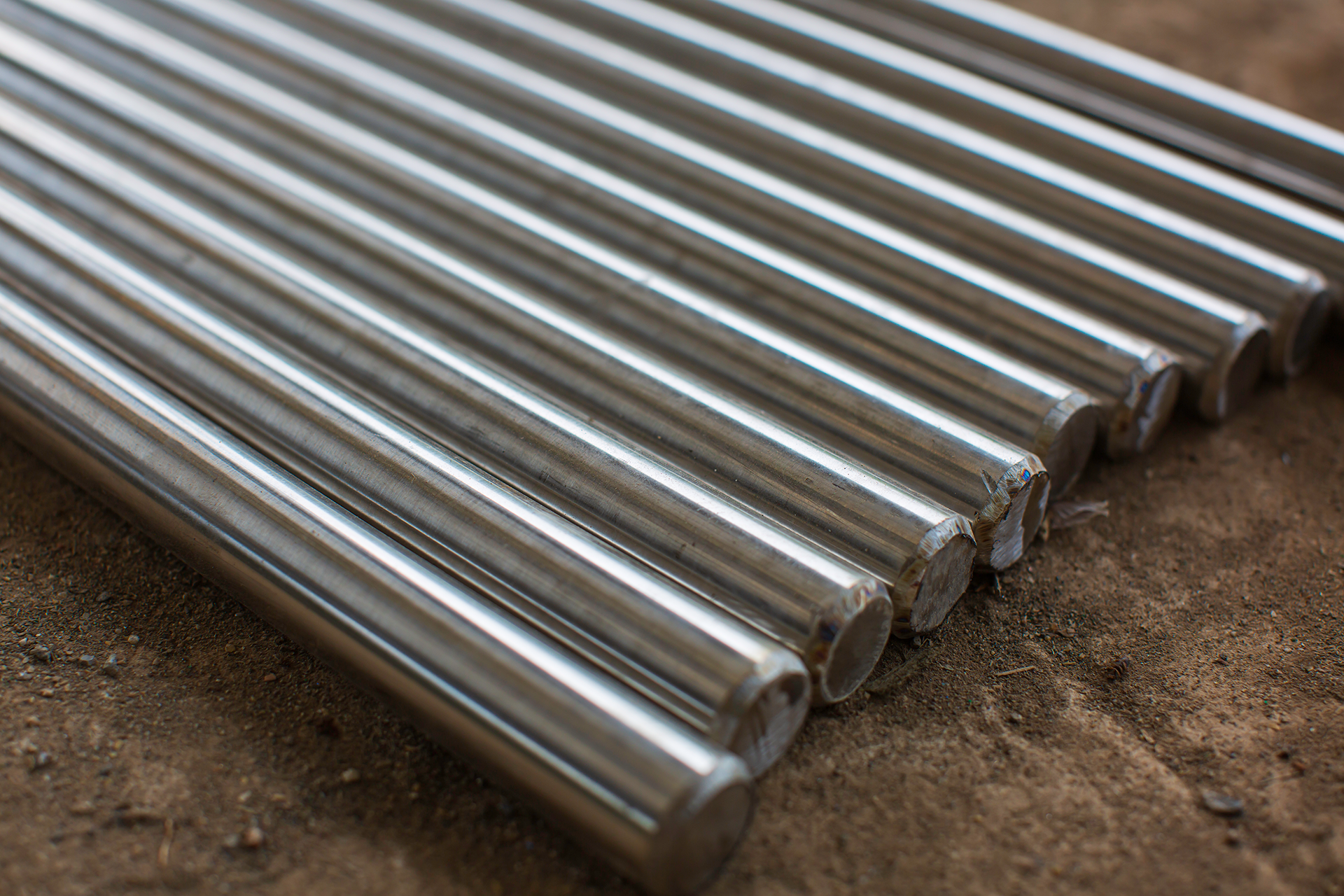

- Marine Fabrication: Boat hulls, gangways, ramps, trailer parts

- Architectural Elements: Decorative panels, railings, siding

- Transportation Equipment: Truck beds, fuel tanks, trailer frames

- Storage and Containment: Pressure vessels, toolboxes, chemical tanks

- Fabrication Shops: Cut-to-length blanks, rolled parts, welded enclosures

Because it's easy to cut, shape, and weld, fabricators can confidently use 5052 for both short-run prototypes and long-term production.

Working with 5052 Aluminum at Action Stainless

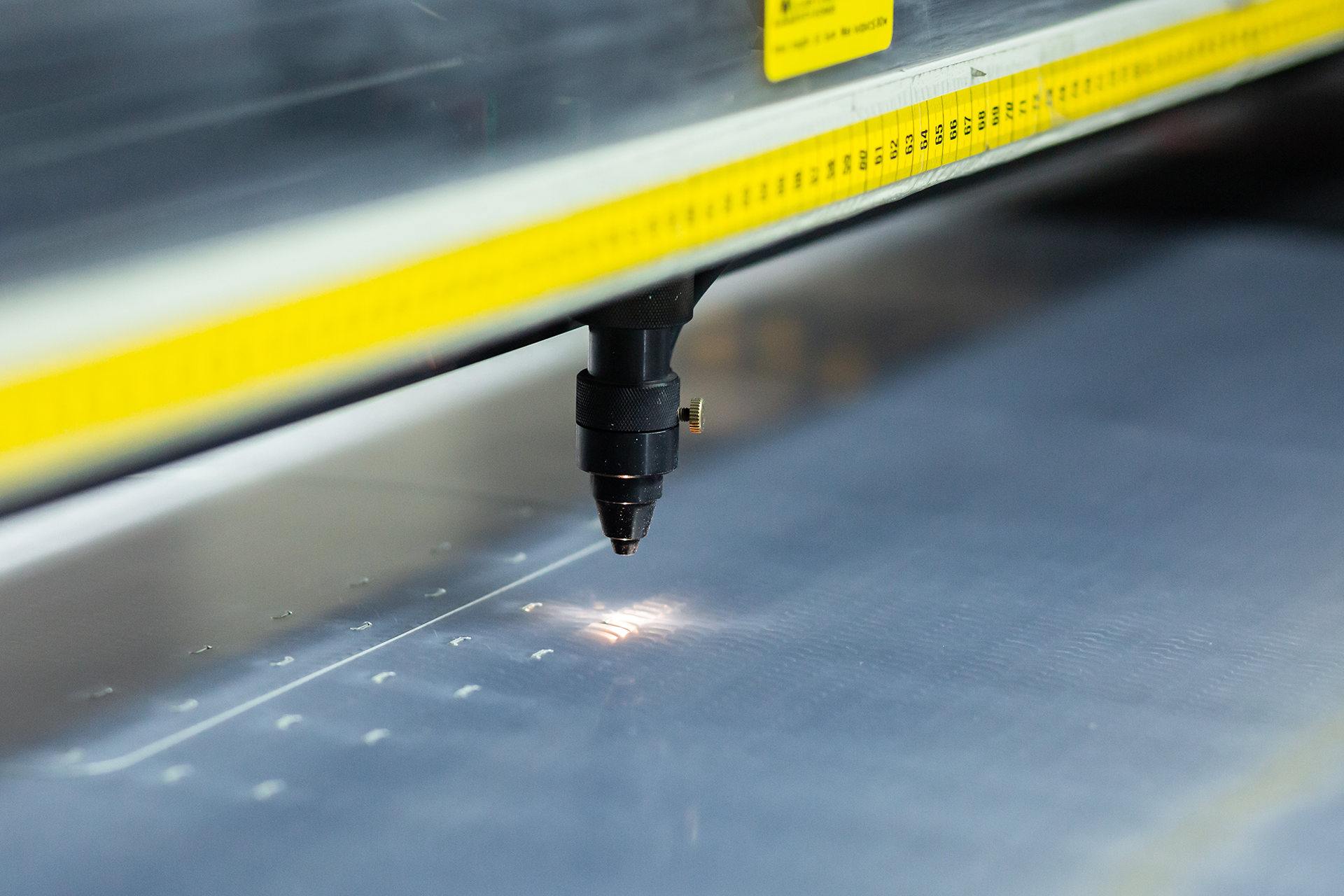

At Action Stainless, we supply 5052 aluminum in sheet, plate, and cut form, ready to integrate into your next project. With extensive in-house capabilities including CNC machining, waterjet cutting, press brake forming, and saw cutting, we can precision-cut 5052 material to meet exact tolerances and designs.

Whether you need a corrosion-resistant component for marine fabrication or a formed aluminum part for structural framing, our team helps deliver the material and services you need, quickly and efficiently.

Ready to Fabricate with 5052?

5052 aluminum continues to be one of the most trusted materials for projects that demand lightweight durability, corrosion resistance, and fabrication versatility. Its performance in saltwater and structural environments makes it the go-to alloy for marine and industrial applications alike.

If you're building something that has to last whether it's a boat frame, a bracing system, or a tank body Action Stainless can help you source and shape the right grade of aluminum to get the job done right.

Contact us today to discuss 5052 aluminum material options and fabrication services tailored to your next project.