The Role of Metal Alloys in Fire-Rated Kitchen and Ventilation Equipment

Commercial kitchens, industrial food processing lines, and institutional cooking environments demand more than basic performance from their equipment. Fire-rated enclosures, hoods, and ventilation systems must meet strict codes for fire resistance, hygiene, and durability. At the core of these high-performance systems is the right choice of metal alloys, which impact everything from fire safety to corrosion resistance.

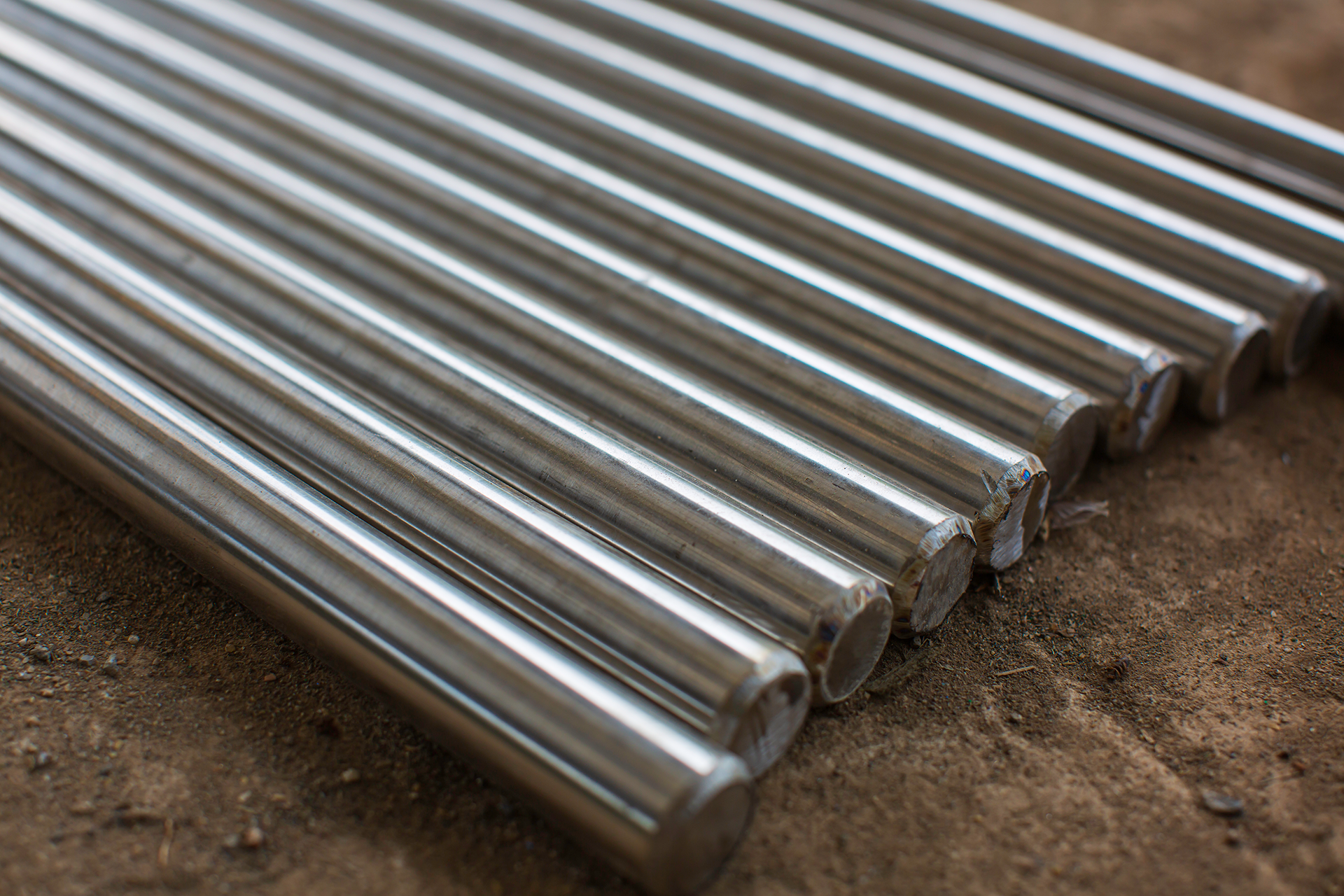

Stainless steel has become the material of choice for fire-rated kitchen and ventilation components due to its balance of thermal resilience, cleanliness, strength, and design flexibility. Action Stainless supports fabricators, OEMs, and facility designers with a full inventory of sheet, plate, and custom-finished bar in grades ideal for this application.

Key Requirements for Fire-Rated Kitchen & Ventilation Equipment

In high-risk environments like commercial kitchens, materials must comply with local fire codes, NSF standards, and ventilation requirements. Common requirements include:

- Fire resistance per UL 710 and other relevant standards

- Non-combustibility and structural integrity at elevated temperatures

- Easy-to-clean and non-porous surface to meet hygiene codes

- Resistance to steam, grease, cleaning agents, and temperature fluctuations

Stainless steel alloys can satisfy all of these, but only when specified correctly. Knowing the differences in alloy performance is essential..

Common Stainless Alloys in Fire-Rated Kitchen & Ventilation Applications

| Alloy | Key Properties | Best Uses | Limitations |

|---|---|---|---|

| 304 SS | High corrosion resistance, non-magnetic, excellent workability | Hoods, panels, ducting, splash guards | Less heat resistance than 430 or 310 |

| 430 SS | Good oxidation resistance, magnetic, more affordable | Exhaust enclosures, vent trims, wall panels | Less corrosion resistance in wet areas |

| 310 SS | Excellent high-temp strength, resistant to oxidation up to 2000°F | High-temperature ducts, heating elements | Higher cost and harder to form |

| Aluminized Steel | Heat-reflective coating, low cost | Some budget enclosures, not for wet areas | Poor corrosion resistance, coating can degrade |

304 vs. 430: The Two Workhorses

304 stainless steel remains a top pick due to its balance of corrosion resistance and versatility. It performs well against steam, cooking oils, and cleaning agents. It’s also non-magnetic and easy to clean critical in NSF-approved kitchen spaces.

430 stainless steel, on the other hand, offers a more budget-friendly option and holds up well in dry heat. Its magnetic quality also makes it suitable for applications where grounding or magnet mounting is required. However, it may underperform in humid or corrosive environments.

Fire Safety and Compliance

UL-listed ventilation hoods and fire suppression systems often require components to maintain structural performance under high heat. The alloy must not melt, warp, or release toxic fumes.

- 304 and 310 stainless steels maintain structural strength at elevated temperatures

- 430 stainless is acceptable for lower-risk environments where code allows magnetic grades

Your design or fabrication choice should always align with the level of fire exposure, cleaning process, and compliance required in your project’s jurisdiction.

Role of Alloy Selection in Fabrication

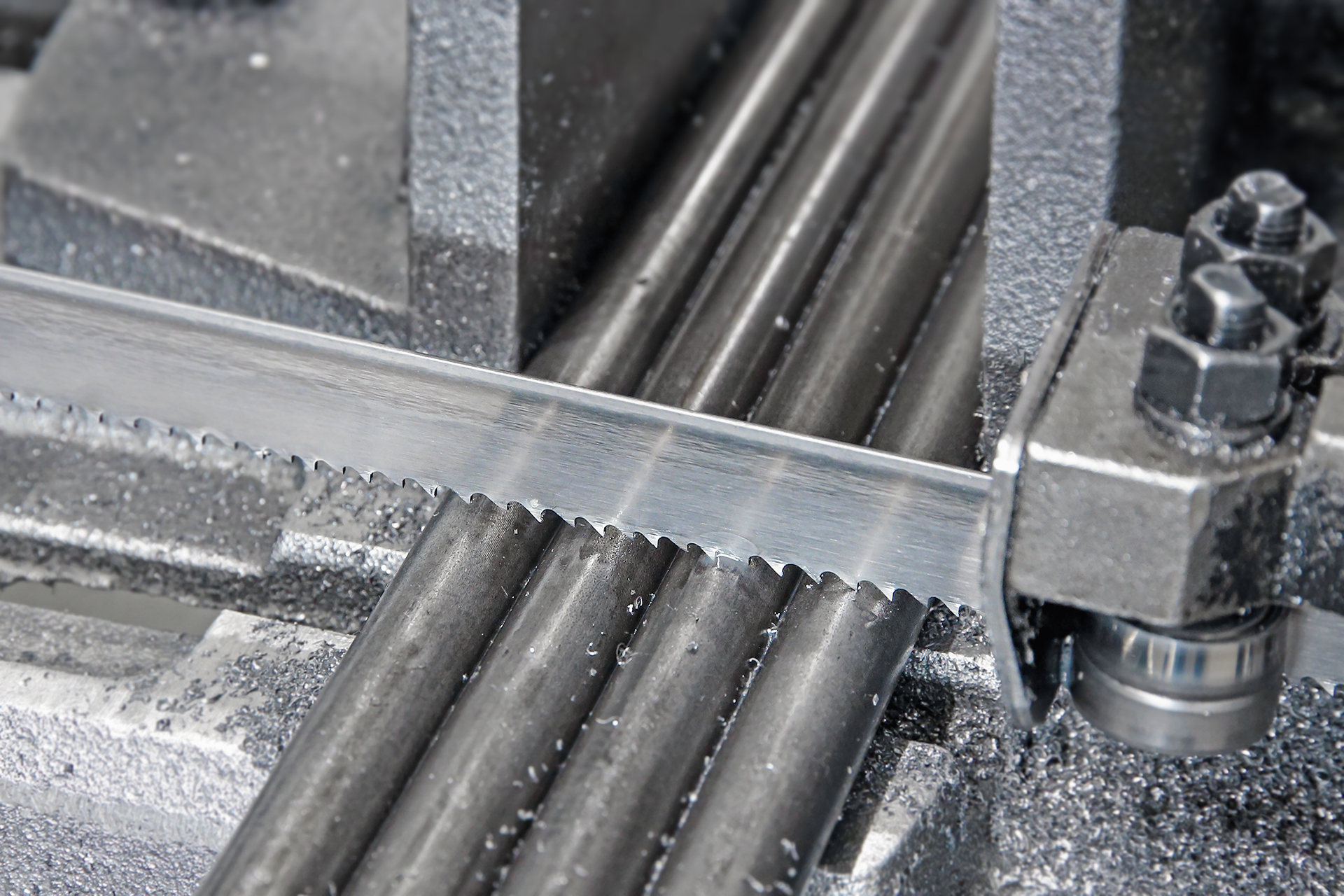

Choosing the right alloy also impacts how easily your parts can be cut, bent, welded, or polished:

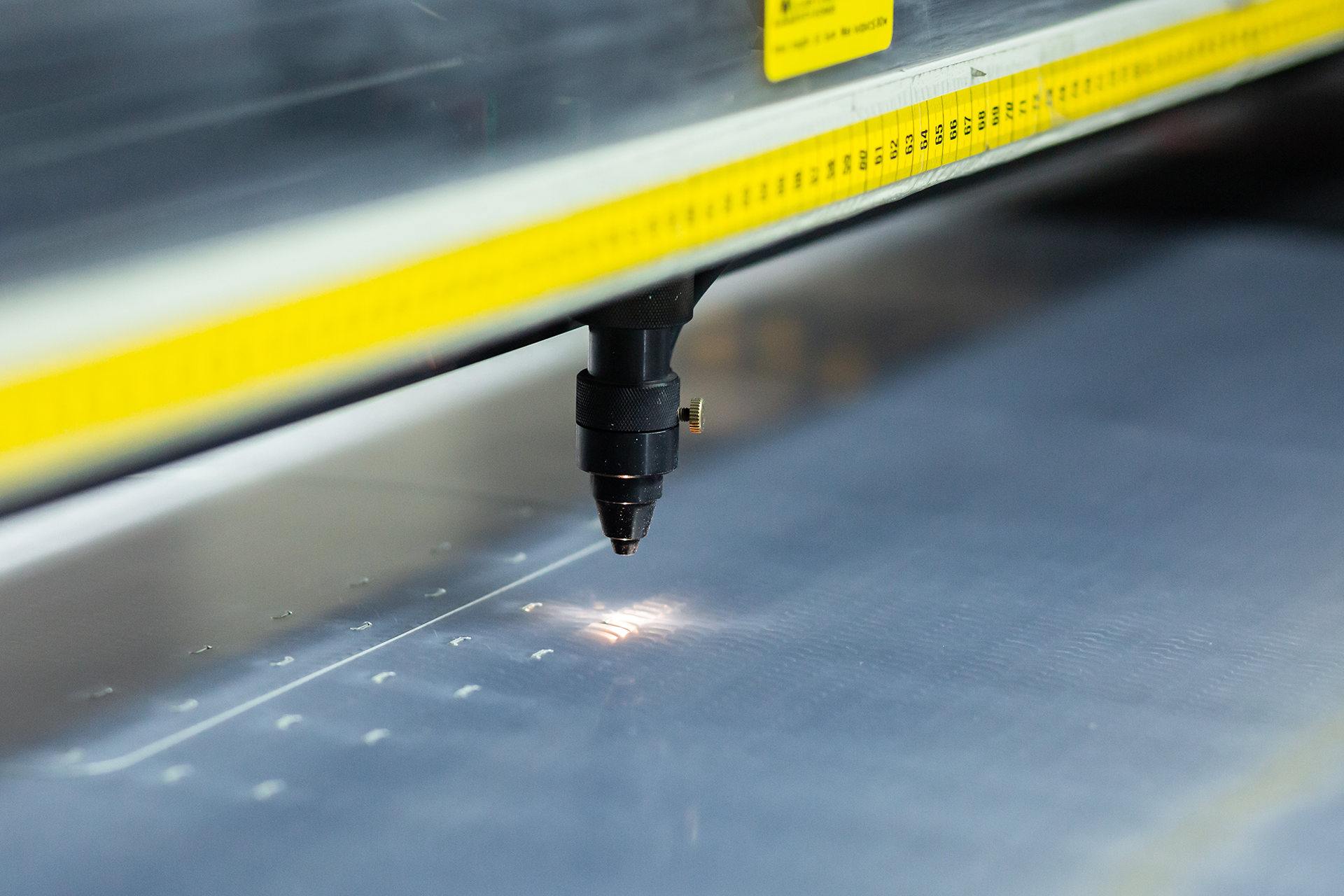

- 304 SS is very weldable and can be laser or plasma cut cleanly.

- 430 SS forms well but may crack in tight bends.

- 310 SS requires more advanced forming and welding processes.

Action Stainless supports your process with in-house services for cutting, forming, polishing, and sourcing specialty grades. Whether you're outfitting an institutional kitchen or fabricating high-performance hoods, we help reduce material waste and speed up production.

When to Use Aluminized Steel

Aluminized steel has a heat-reflective surface and is used in some budget or dry-air applications. But it cannot match stainless for corrosion resistance, especially around water and cleaning agents. It's a trade-off between cost and lifespan.

If your design doesn’t involve regular exposure to moisture or food contact and where code allows aluminized steel may be used in areas such as back panels or secondary enclosures. But most mission-critical systems will still benefit from 304 or 430 stainless.

Working With Action Stainless

Choosing the right alloy is only the beginning. Action Stainless provides technical support, product availability, and material preparation services that save time and costs on fire-rated and NSF-certified kitchen builds.

- Stock in 304, 430, 310, and specialty grades

- Custom cutting and shearing to your specs

- Finishes suitable for food-contact and visible surfaces

We help fabricators, OEMs, and commercial designers source the right metal, in the right form, with the right finish, ready to perform in fire-rated systems.

Looking to start your next fire-rated kitchen or ventilation project? Work with Action Stainless to get the right material matched to your application, budget, and timeline.