Why Stainless Steel is the Preferred Material for Commercial Kitchens

In the fast-paced, high-demand environment of commercial kitchens, material choice is critical. From prep surfaces to sinks, shelving, and cooking equipment, stainless steel stands out as the industry standard and for good reason. Known for its durability, sanitation, and ease of maintenance, stainless steel is the backbone of countless foodservice facilities across the country.

At Action Stainless, we support commercial kitchen fabricators, foodservice providers, and equipment manufacturers with in-stock stainless products, processing services, and technical guidance to ensure compliance and efficiency in food-safe environments.

The Hygienic Advantage of Stainless Steel

In commercial kitchens, hygiene is non-negotiable. Stainless steel's non-porous surface resists bacterial growth, making it ideal for food prep and clean-room environments. Unlike wood or laminate, it doesn't harbor moisture or odors. When cleaned properly, it meets or exceeds public health codes and NSF requirements.

Grades such as 304 and 316 are especially common in foodservice due to their corrosion resistance and compatibility with cleaning agents and sanitizers. Action Stainless offers stainless sheet and tube in both grades, ready for use in food contact surfaces, wash-down equipment, and wet environments.

Durability Under Pressure

Commercial kitchens operate under constant wear, high heat, spills, impacts, and rigorous cleaning routines. Stainless steel is up to the task. It resists corrosion from food acids and cleaning chemicals, won’t warp under thermal shock, and stands up to everyday abuse from pots, pans, and cutlery.

With stainless grades like 304L and 316L, which offer enhanced corrosion resistance and weldability, kitchen designers can fabricate durable equipment without sacrificing strength or longevity. At Action Stainless, we provide mill finish and polished sheet options designed for heavy-duty use.

Easy to Clean and Maintain

One of the biggest advantages of stainless steel in a kitchen environment is how easy it is to clean. Smooth surfaces prevent residue buildup, while polished finishes enhance both appearance and sanitation. From prep tables to splash guards, stainless steel requires little more than soap and water or a commercial-grade degreaser.

Polished finishes like No. 4 (brushed) or BA (bright annealed) are common in kitchen installations. These finishes offer the best balance of visual appeal and ease of cleaning, especially in visible or high-traffic areas.

Fire and Heat Resistance

With cooking equipment and open flames present, fire safety is always a consideration. Stainless steel provides excellent heat and flame resistance, making it suitable for stovetops, range hoods, backsplash panels, and oven components.

Because it retains strength at high temperatures, stainless steel can be used where other materials might deform, delaminate, or combust. This makes it indispensable in applications like commercial fryers, grill surrounds, and equipment enclosures.

Stainless Grades Commonly Used in Kitchens

| Grade | Description | Typical Use |

|---|---|---|

| 304 | Most common food-grade stainless, excellent corrosion resistance | Sinks, tables, dishwash stations |

| 304L | Low-carbon version of 304, better weld performance | Equipment frames, custom weldments |

| 316 | Higher corrosion resistance due to molybdenum | Seafood prep, salt-heavy environments |

| 316L | Low-carbon 316, minimizes weld decay | High-sanitation and CIP systems |

At Action Stainless, these grades are stocked in sheet, tube, angle, and bar formats, many available polished and cut-to-length.

Formability and Fabrication Benefits

Fabricators appreciate how well stainless steel can be cut, bent, welded, and finished. Action Stainless supports this process with:

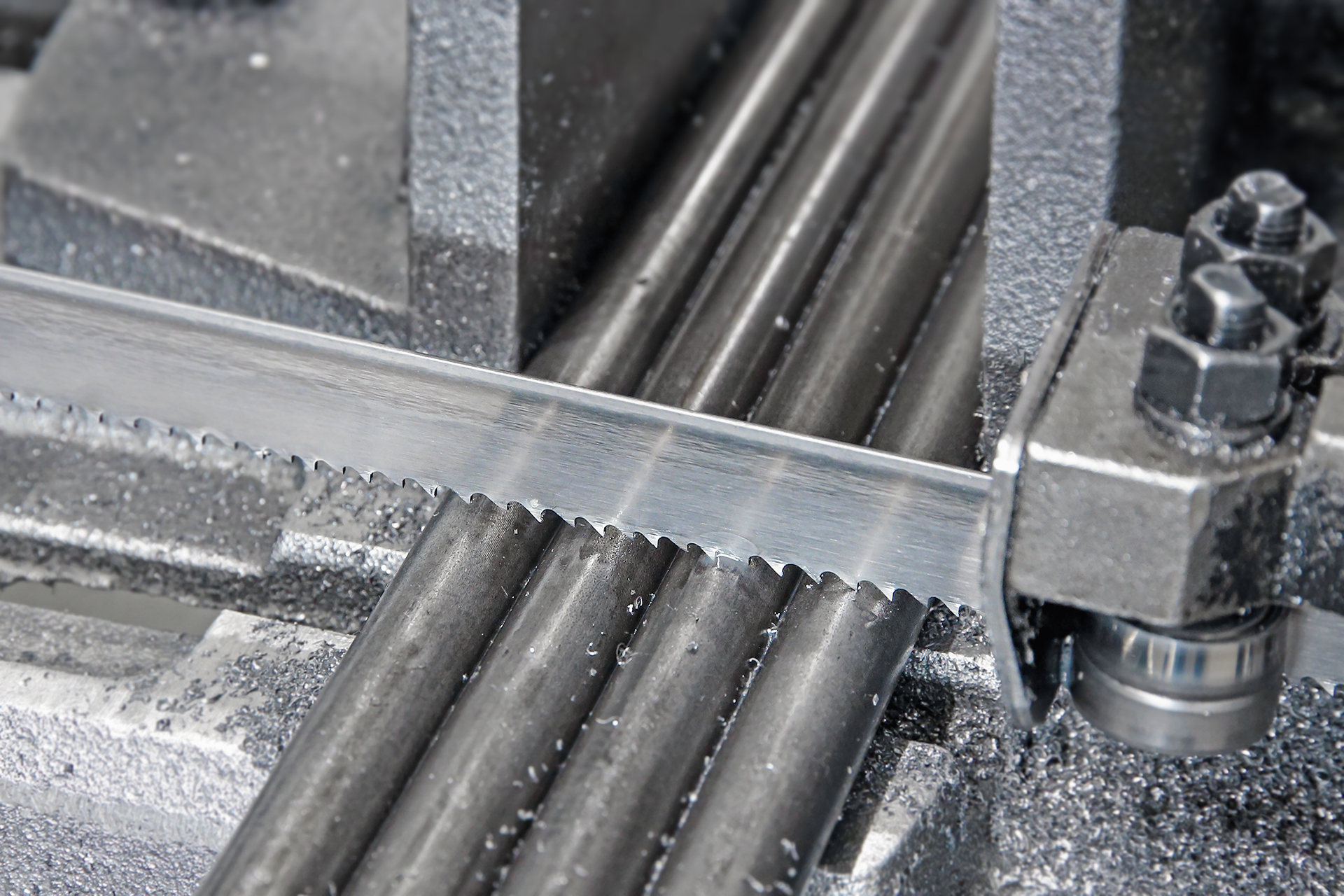

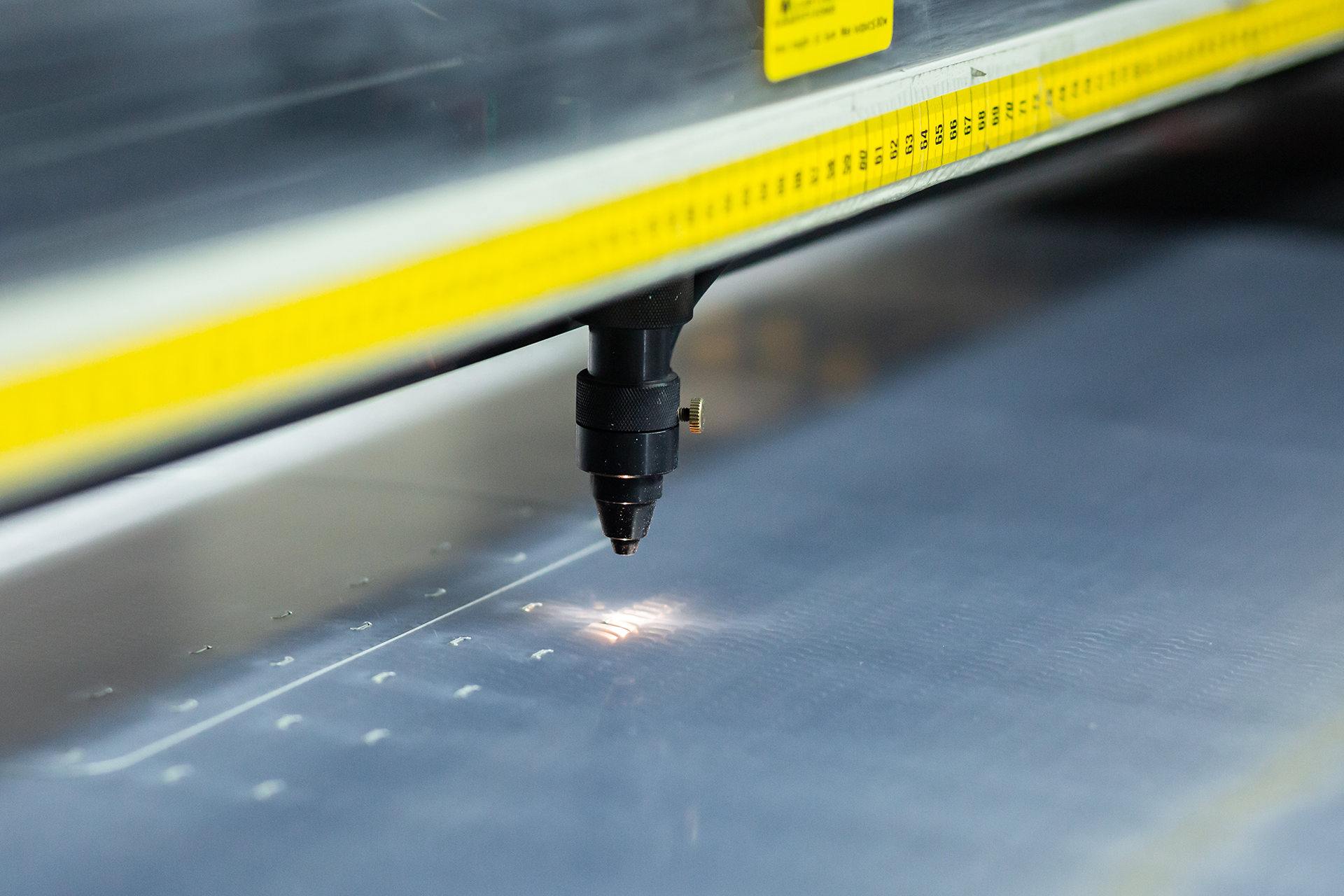

- Laser and waterjet cutting for clean edges and complex shapes

- Press brake forming for sinks, cabinets, and countertops

- Polishing for NSF-compliant sanitary finishes

- Shear and saw cutting to streamline kitchen component fabrication

From CAD to finished part, our in-house processing team helps commercial kitchen manufacturers speed up production and reduce scrap.

Longevity That Pays Off

While stainless steel may carry a higher upfront cost than alternative materials, its long lifespan, low maintenance needs, and resistance to damage offer long-term savings. Unlike coated or painted surfaces, stainless won't chip or require reapplication. That makes it a smart investment for commercial operators aiming to minimize downtime and maintenance expenses.

When properly maintained, stainless steel can last decades in a kitchen setting, even under intense daily use.

Regulatory Compliance & Food Safety Standards

NSF International, the FDA, and local health departments all recognize stainless steel as a food-safe material. Most commercial kitchen equipment must meet NSF standards, which specify:

- Smooth, non-absorbent surfaces

- No exposed seams or crevices

- Resistance to corrosion and pitting

By sourcing NSF-compliant stainless materials from Action Stainless, fabricators can design and build with confidence, knowing their equipment will pass inspection and operate safely.

Industries and Applications We Support

Our stainless products support a wide range of kitchen and foodservice environments, including:

- Restaurant kitchens and prep lines

- Institutional cafeterias and commissaries

- Food trucks and mobile kitchens

- Bakeries and deli operations

- Meat and seafood processing stations

- Breweries and commercial beverage facilities

With nationwide distribution and deep inventory, we help fabricators meet short lead times and evolving project demands.

Work With Action Stainless on Your Next Kitchen Build

Whether you're outfitting a small bistro or building a large-scale foodservice facility, stainless steel remains the material of choice for commercial kitchen success. At Action Stainless, we pair quality materials with responsive service and expert guidance.

Contact us today to explore stocked kitchen-grade stainless, request cut-to-size components, or speak with a specialist about your next kitchen build.