ASTM Stainless Steel Standards | Guide for Plate, Sheet & Pipe Orders

In the stainless steel industry, precision matters but compliance matters even more. Whether you're ordering stainless sheet for a sanitary environment or pipe for industrial pressure systems, understanding the relevant ASTM standards can prevent costly mistakes and ensure your material meets performance and regulatory expectations.

At Action Stainless, we stock and process stainless steel plate, sheet, and pipe to meet the industry's most recognized ASTM specifications. In this guide, we break down which ASTM standards matter most when ordering stainless products and how they impact your fabrication project.

Why ASTM Standards Are Critical in Stainless Steel Procurement

ASTM International sets the technical specifications for materials used in industrial, commercial, and structural applications. When you reference an ASTM standard, you're ensuring consistency, traceability, and safety across sourcing, fabrication, and installation.

Not all stainless products are created equally. Two sheets may look identical but perform very differently under pressure, corrosion, or welding conditions. ASTM designations help engineers, fabricators, and purchasing teams confidently choose the right product for their environment.

ASTM standards also provide assurance to regulators, inspectors, and end users that the material is qualified for use in hygienic systems, pressure-rated installations, or code-compliant structural applications.

Key ASTM Standards for Stainless Steel Plate and Sheet

ASTM A240: Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

This is the primary standard used for stainless steel plate and sheet rolled for pressure vessels, heat exchangers, structural use, and general applications. Grades like 304, 304L, 316, and 316L fall under ASTM A240.

Why it matters:

- Covers material composition and mechanical properties

- Ensures plate and sheet meet corrosion resistance expectations

- Guides fabrication in high-temperature or sanitary settings

- Used in sectors including food processing, marine equipment, and chemical handling

At Action Stainless, all of our stocked sheet and plate is sourced to meet ASTM A240 requirements. This includes mill finish and polished material with documentation available upon request.

ASTM A480: General Requirements for Flat-Rolled Stainless Products

While A240 defines the grade and intended use, A480 governs dimensional tolerances, flatness, finish, and surface quality. It acts as a foundational reference standard for most flat-rolled stainless.

Why it matters:

- Establishes surface finish types (e.g., 2B, No. 4, BA)

- Defines allowable tolerances for thickness, width, and flatness

- Standardizes requirements across mills and suppliers

- Supports consistency for polished or sanitary-finish applications

ASTM A480 ensures that your flat stainless material not only meets chemical spec but is also suitable for processing, polishing, or sanitary finish.

Key ASTM Standards for Stainless Steel Pipe

ASTM A312: Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe

This is the go-to standard for stainless pipe used in high-pressure or corrosive industrial applications. It covers grades like 304, 304L, 316, and 316L in both seamless and welded form.

Why it matters:

- Specifies minimum yield and tensile strength for pipe

- Sets guidelines for heat treatment and testing

- Ensures pressure-capable performance in process piping, refineries, and chemical plants

- Used widely in water treatment and sanitary processing

All stainless pipe from Action Stainless meets ASTM A312 unless specified otherwise. Customers receive complete mill test reports and traceability documentation.

ASTM A778: Welded, Unannealed Austenitic Stainless Steel Tubular Products

While A312 is intended for high-pressure and structural use, A778 is used for ornamental and low-pressure applications where annealing is not required.

Why it matters:

- Cost-effective alternative for non-critical pipe and tube use

- Applicable for architectural, decorative, and non-pressure conveying systems

- Faster lead times and lower material costs

Products conforming to A778 are available from Action Stainless for railings, trim, and low-load tubing installations.

Understanding Dual Certification: A240 vs. A666

You may also encounter dual-certified stainless products, especially in sheet and coil. For example, some stainless sheets carry both A240 and A666 certifications.

ASTM A666 covers annealed or cold-worked austenitic stainless sheet, strip, plate, and flat bar. It's used for products where forming and corrosion resistance are key.

At Action Stainless, dual-certified sheet allows our customers greater flexibility, especially in forming or deep-draw applications such as appliance panels, sanitary cladding, or HVAC trays.

Why ASTM Specs Should Be on Every Purchase Order

Specifying ASTM standards on your P.O. ensures:

- Traceability: You can match every item to a mill test report (MTR)

- Regulatory Compliance: Necessary for FDA, ASME, or NSF requirements

- Reduced Risk: Eliminates ambiguity or assumptions in fabrication and QA

Our documentation includes:

- Heat numbers and production lot IDs

- Mill test reports (MTRs) for each product

- Certificate of conformance on request

If you’re unsure what spec your project needs, our team is here to help. We speak ASTM fluently and can assist in interpreting application requirements.

Industries That Depend on ASTM-Certified Stainless

At Action Stainless, our plate, sheet, and pipe products support a wide range of industries, including:

- Food and Beverage: Sanitary-grade finishes and chemical resistance

- Chemical Processing: ASTM A312 pipe for high-pressure media

- Water Treatment: Corrosion-resistant 316 plate per ASTM A240

- Pharmaceutical: Dual-certified 316L sheet with No. 4 finish

- Architecture: ASTM A778 pipe for handrails and trim

- OEM & Fabrication: ASTM-compliant sheet and pipe for structural applications

Each sector has strict performance standards and ASTM specs help meet those consistently.

Real-World Use: Stainless Plate and Pipe in Practice

Imagine a fabrication project for a wastewater treatment facility that requires long-lasting pipe to handle chlorinated media. By sourcing 316L stainless pipe certified to ASTM A312, the purchasing team ensures pressure resistance, corrosion protection, and compliance with municipal and environmental codes.

Or, take an architectural firm needing polished handrails for an upscale hotel. ASTM A778-compliant tubing offers both form and function, with the finish options and dimensional tolerances to fit pre-designed supports.

These real-world cases show how ASTM standards act as a language of quality ensuring the material you get matches the environment it will perform in.

Partner with Action Stainless for ASTM-Compliant Material

Whether you need pressure-rated pipe or polished plate for architectural cladding, ASTM standards are your blueprint for performance and safety. At Action Stainless, we don’t just meet specs we help you understand them.

Our team is here to:

- Review application requirements

- Provide ASTM-compliant inventory

- Deliver MTRs and documentation with every order

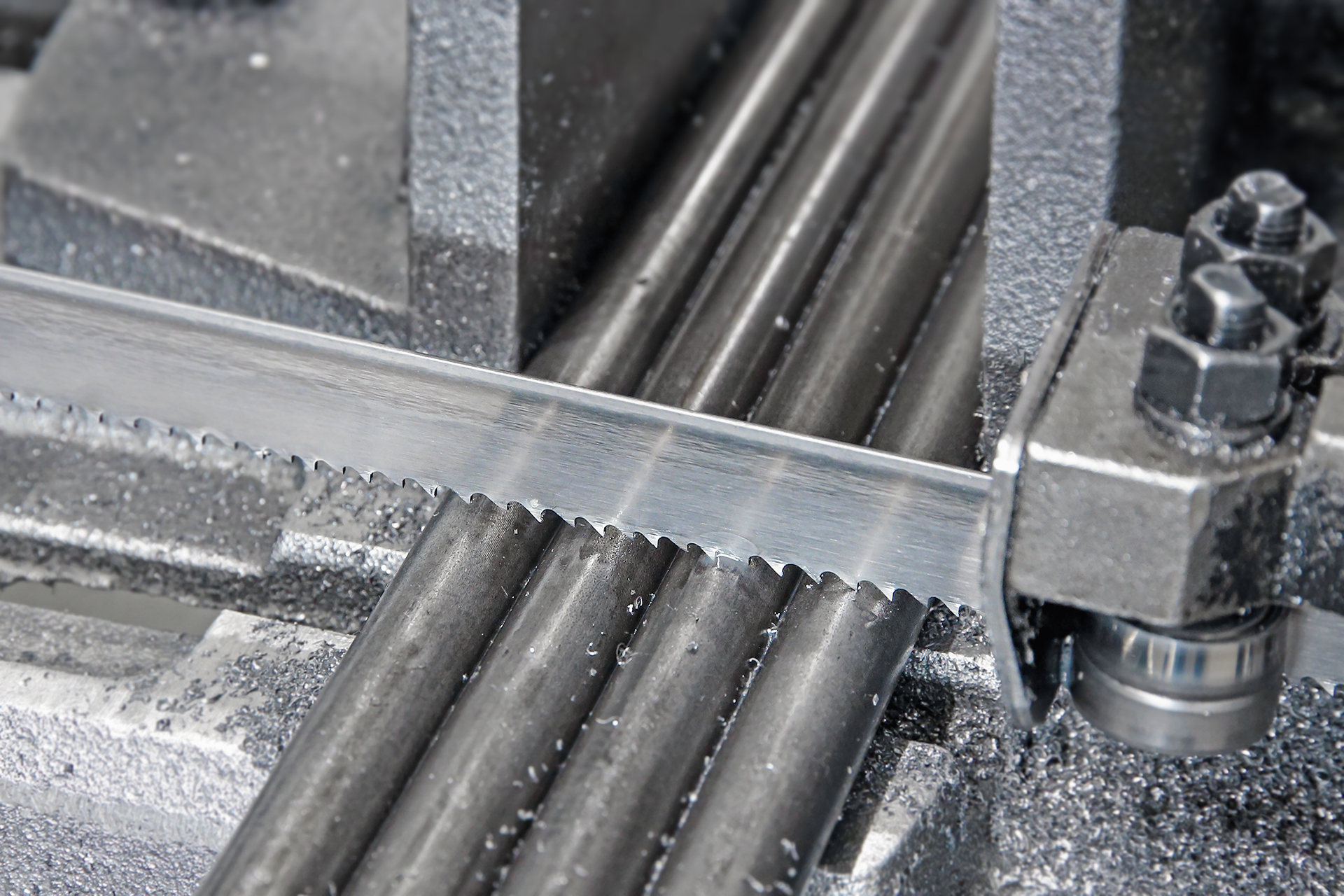

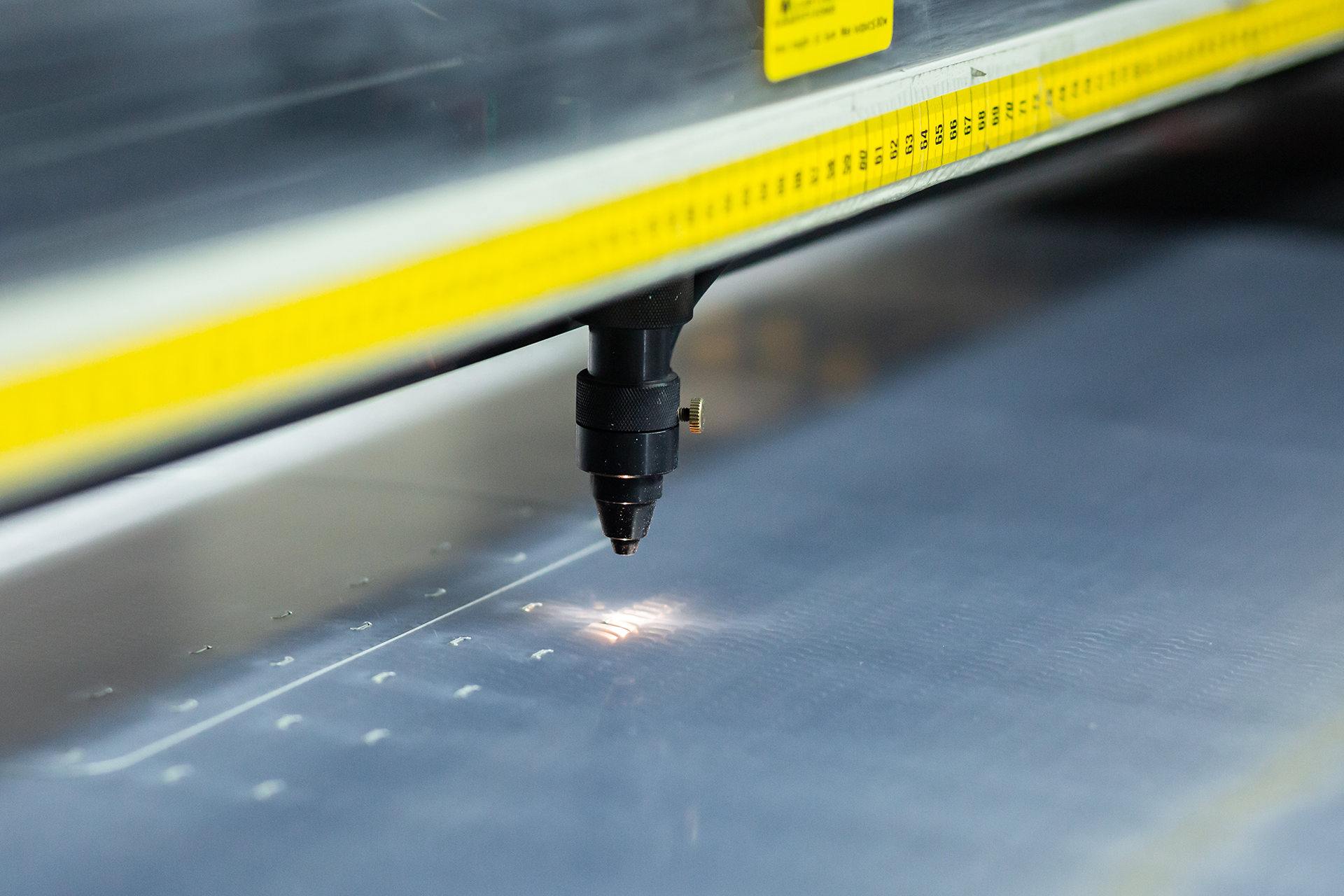

- Cut, polish, or form to spec with in-house processing

Need help placing a stainless order with ASTM specs?

Contact your Action Stainless representative today for a quote or technical guidance.