The Advantages of Centerless Ground Bar for Pump Shaft Applications

When durability, precision, and performance are required in pump shaft applications, few materials perform as reliably as centerless ground stainless steel bar. Designed for demanding rotational and high-load systems, centerless ground bar offers the straightness, surface finish, and tight tolerances needed in pumps used across chemical processing, water treatment, energy, and marine industries. At Action Stainless, we supply and process pump shaft-quality bar in stainless grades that meet or exceed industry expectations.

What Is Centerless Ground Bar?

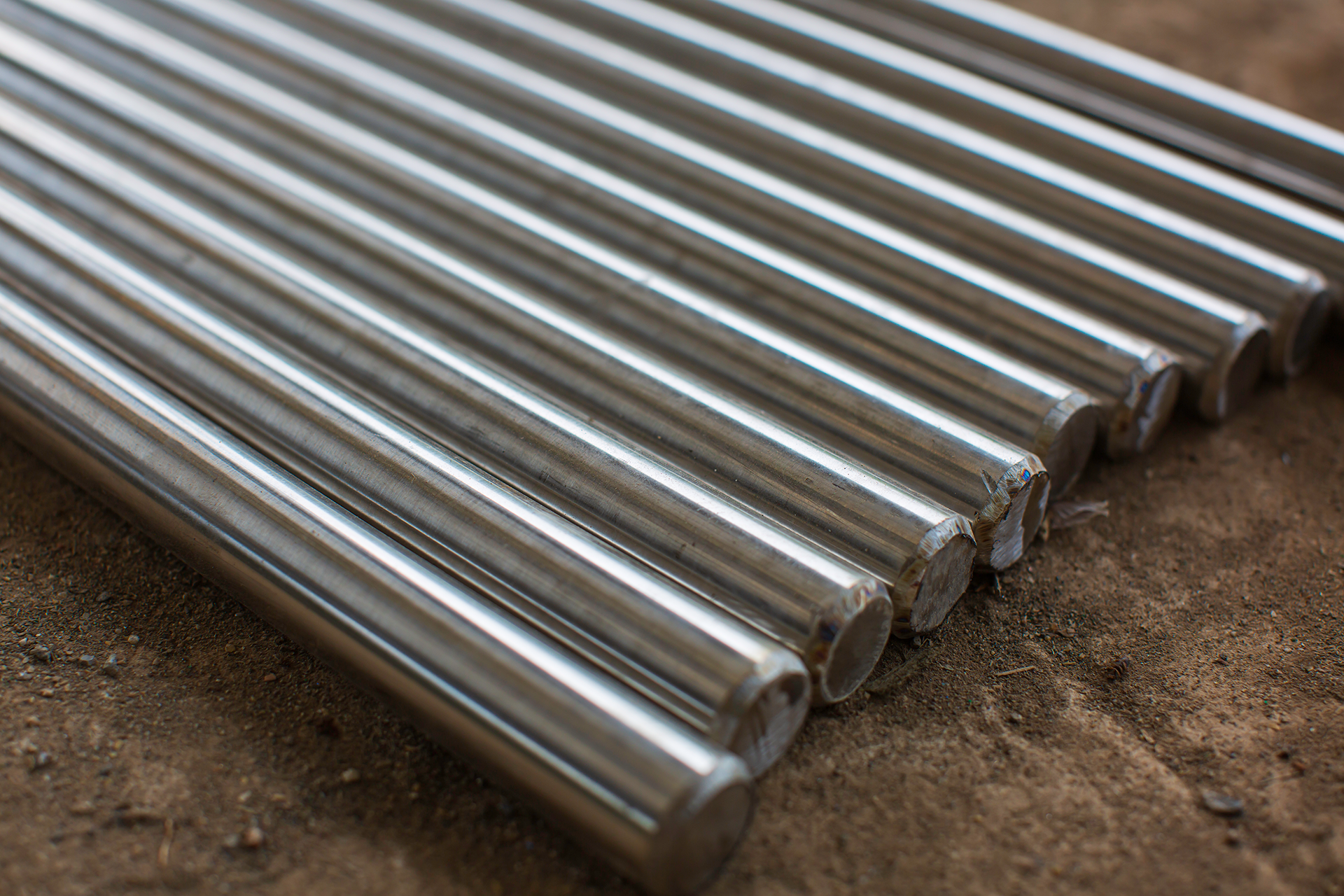

Centerless grinding is a precision finishing process that removes material from the outer surface of a bar without the use of a spindle or chuck. Unlike traditional cylindrical grinding, centerless grinding uses a regulating wheel and a grinding wheel to shape and polish the bar as it passes through. This method produces a smooth, consistent diameter along the entire length of the bar, with exceptional straightness and surface integrity.

At Action Stainless, our ground bar meets exacting shaft tolerances and is ideal for applications where runout and surface condition directly affect equipment life and pump performance.

Why Centerless Ground Bar Matters for Pump Shafts

Pump shafts must endure continuous rotation, axial and radial loads, and corrosive or abrasive fluids. Using a ground stainless bar ensures improved alignment, lower friction, and longer service life. The result is better reliability, extended equipment lifespan, and fewer breakdowns in the field.

The use of centerless ground bar ensures:

- Enhanced straightness: reduces vibration and improves bearing alignment

- Improved surface finish: supports better sealing and lowers friction

- Tight tolerances: allows for consistent shaft fit in OEM assemblies

- Reduced stress risers: smooth finish limits points of mechanical failure

Key Benefits of Using Centerless Ground Bar

1. Precision Tolerances for Critical Alignment

Pumps depend on precise shaft geometry to maintain correct alignment with seals, impellers, and bearings. Centerless grinding produces consistent diameters across long bar lengths, maintaining tolerances as tight as ±0.0002”. This is crucial for high-speed, high-pressure applications where minor deviations can cause efficiency loss or premature wear.

2. Superior Surface Finish for Smooth Operation

The smoother the surface finish, the less friction, vibration, and wear occurs during shaft rotation. Action Stainless provides pump shaft-quality bar with polished finishes (up to 16 Ra or better), minimizing startup torque, seal wear, and operating noise. This contributes directly to system efficiency and energy savings.

3. Greater Fatigue Resistance

Micro-cracks and surface defects from rough machining or inconsistent bar stock can lead to early fatigue failures. Ground bar reduces these stress risers, delivering uniform surface quality that holds up under repetitive cycles. This is especially valuable in continuous-duty pumps found in wastewater plants or cooling systems.

4. Improved Corrosion Resistance with Stainless Grades

We offer centerless ground bar in corrosion-resistant stainless steels such as 303, 304, 316, and other shaft-quality grades. These materials resist degradation from chemicals, saltwater, and aggressive cleaning agents, making them ideal for:

- Marine pump shafts

- Food and beverage process pumps

- Chemical transfer systems

These stainless grades offer long-term resistance even under frequent sanitization or exposure to corrosive process media.

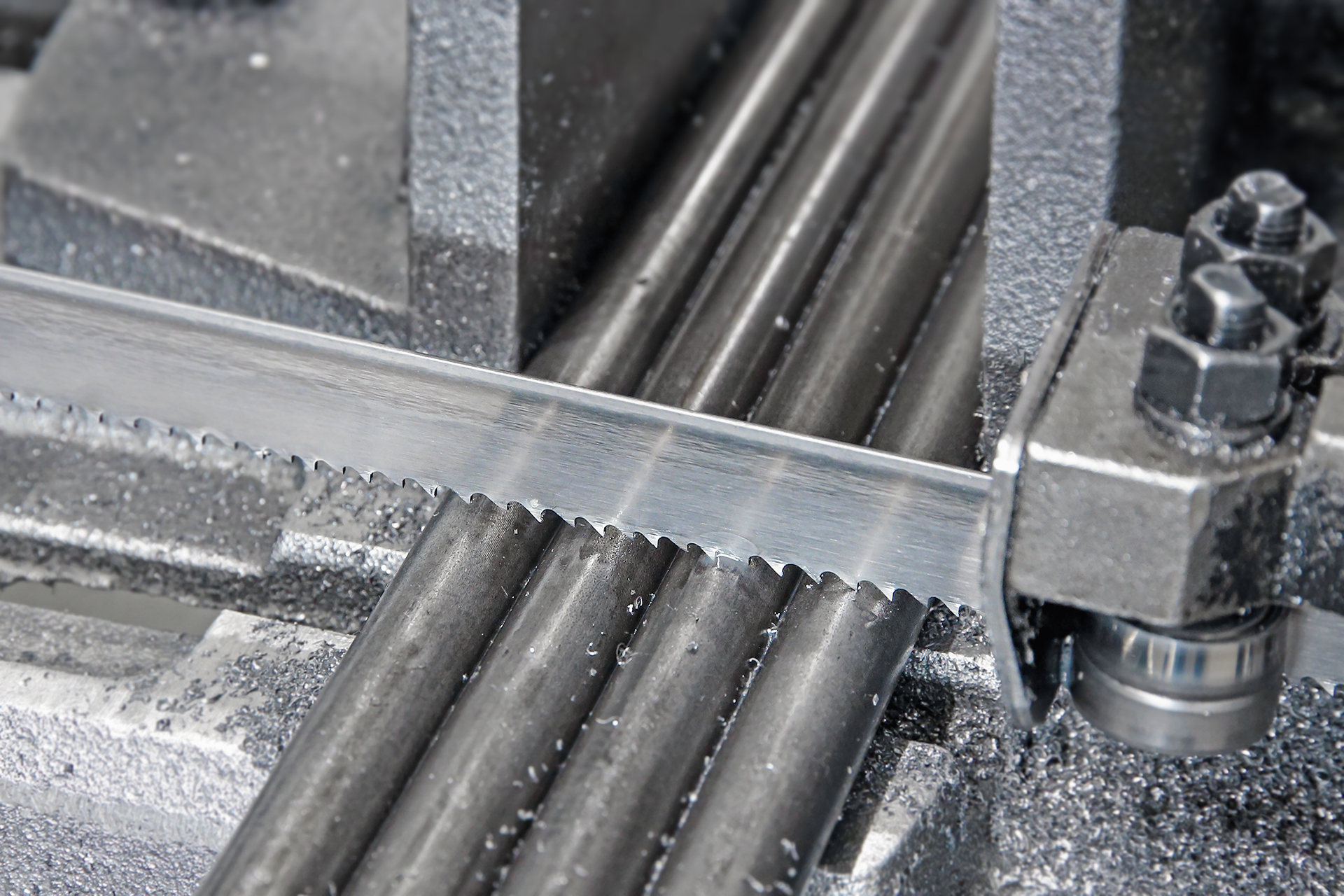

5. Custom Cut-to-Length and Machining Ready

At Action Stainless, we not only stock pump shaft-quality bars we process them to your specification. Our team provides:

- Saw cutting to precise lengths

- Polishing to sanitary or architectural finish

- Value-added fabrication prep including chamfering or threading

With in-house services, your stainless ground bar arrives pump-ready, reducing time to install and speeding up fabrication cycles.

Applications That Rely on Ground Stainless Shaft Bar

Industries that require high-reliability pump systems trust centerless ground stainless bar for:

- Wastewater Treatment Systems

- Desalination and Marine Pumps

- Chemical Processing Equipment

- Food & Beverage Sanitary Systems

- HVAC and Refrigeration Units

Precision is not optional in these environments. Vibration, misalignment, or corrosion can compromise performance and safety.

Common Stainless Grades for Pump Shaft Applications

| Grade | Description | Typical Use Cases |

|---|---|---|

| 303 | Free-machining stainless with good corrosion resistance | General-purpose pump shafts, low-load systems |

| 304 | Versatile, corrosion-resistant stainless | Water and food-grade systems |

| 316 | High corrosion resistance with molybdenum | Marine, chemical, and sanitation systems |

| 416 | Martensitic hardenable alloy with increased sulfur content for improved machinability | General purpose pump shafts and freshwater systems |

At Action Stainless, our stocked shaft-quality grades are selected to meet the challenges of high-stress, high-moisture environments. All material includes mill test reports (MTRs) for full traceability.

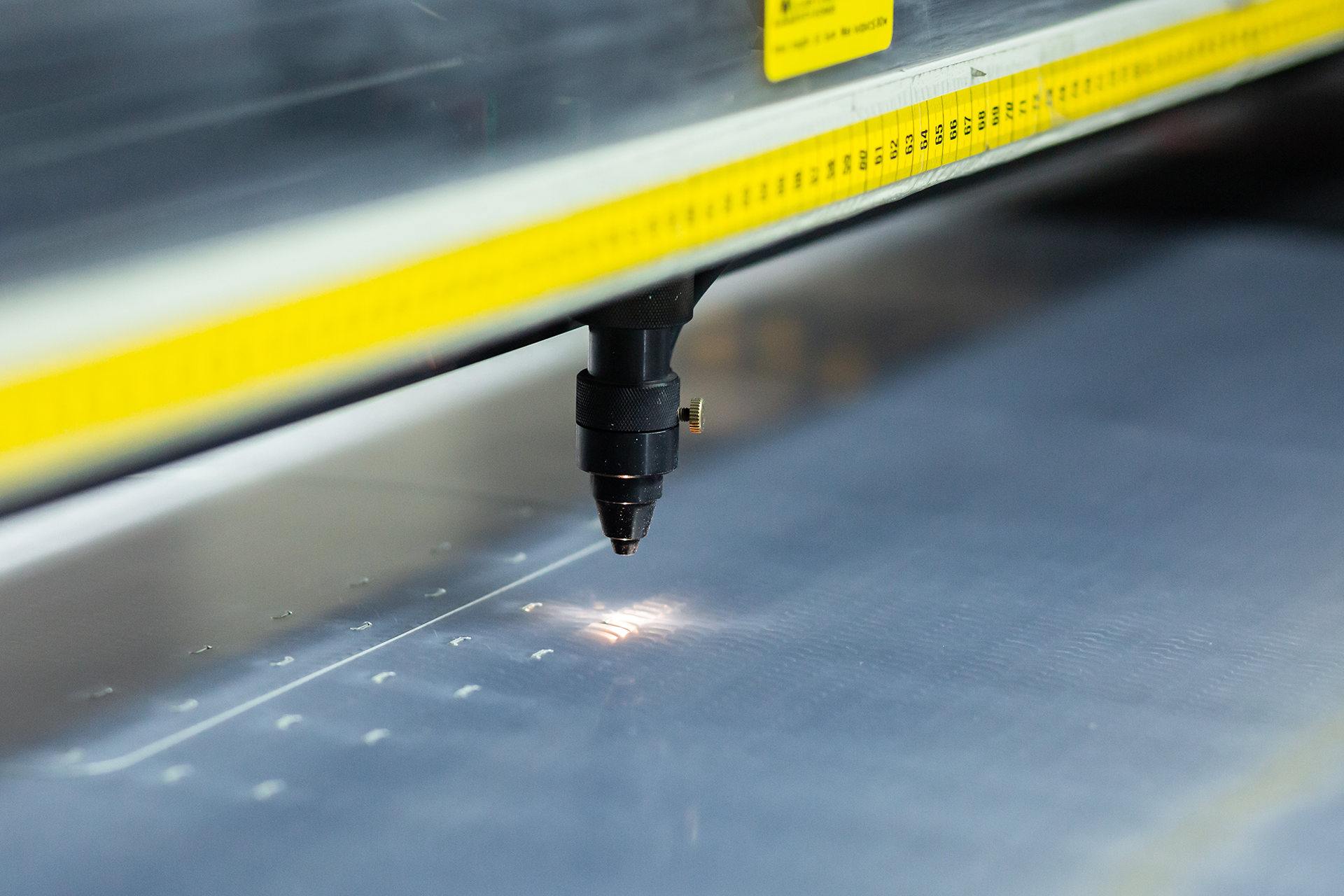

Action Stainless In-House Centerless Bar Services

Our team supports customers with end-to-end supply solutions:

- Precision centerless grinding for bar straightness and polish

- Cut-to-length processing up to 22 feet

- Polishing to meet aesthetic or sanitary standards

- Custom sourcing of shaft quality stainless grades

We combine industry expertise with in-house capabilities to reduce lead times and optimize the cost-performance ratio of your final assembly. Whether you need one prototype or high-volume runs, our processes scale with your demand.

Why Action Stainless?

Our in-depth knowledge of stainless steel behavior, pump system requirements, and machining tolerances means you get more than just material you get a partner in performance. We’ve supported pump manufacturers, fabricators, and OEMs with reliable stainless shaft bars for decades.

We maintain consistent inventory across stocked grades and offer fast turnaround on custom processing. Whether it’s marine-grade corrosion protection or high-speed rotational performance, we’re equipped to meet your needs with precision and consistency.

Partner With Action Stainless

Whether you're building pumps for food processing, marine operations, or chemical plants, Action Stainless provides the precision-ground stainless bar your system needs. With extensive inventory, in-house grinding, and experienced processing teams, we help OEMs and fabricators meet tight tolerances and performance specs.

Looking for centerless ground stainless bar for your next pump system?

Contact Action Stainless to explore stocked shaft bar grades, custom grinding options, or request a quote today.