Cutting Aluminum with Precision: What You Should Know About Waterjet and Saw Services

Aluminum fabrication depends on precision. Whether you're cutting material for frames, enclosures, or OEM components, the accuracy and edge quality of the cut directly impacts the performance and fit of your final product. At Action Stainless, we specialize in aluminum processing using both waterjet and saw cutting technologies, each suited to different requirements based on material thickness, complexity, and final application.

This guide outlines the strengths, limitations, and ideal use cases of both cutting methods, helping you make informed decisions when selecting services for your aluminum fabrication projects.

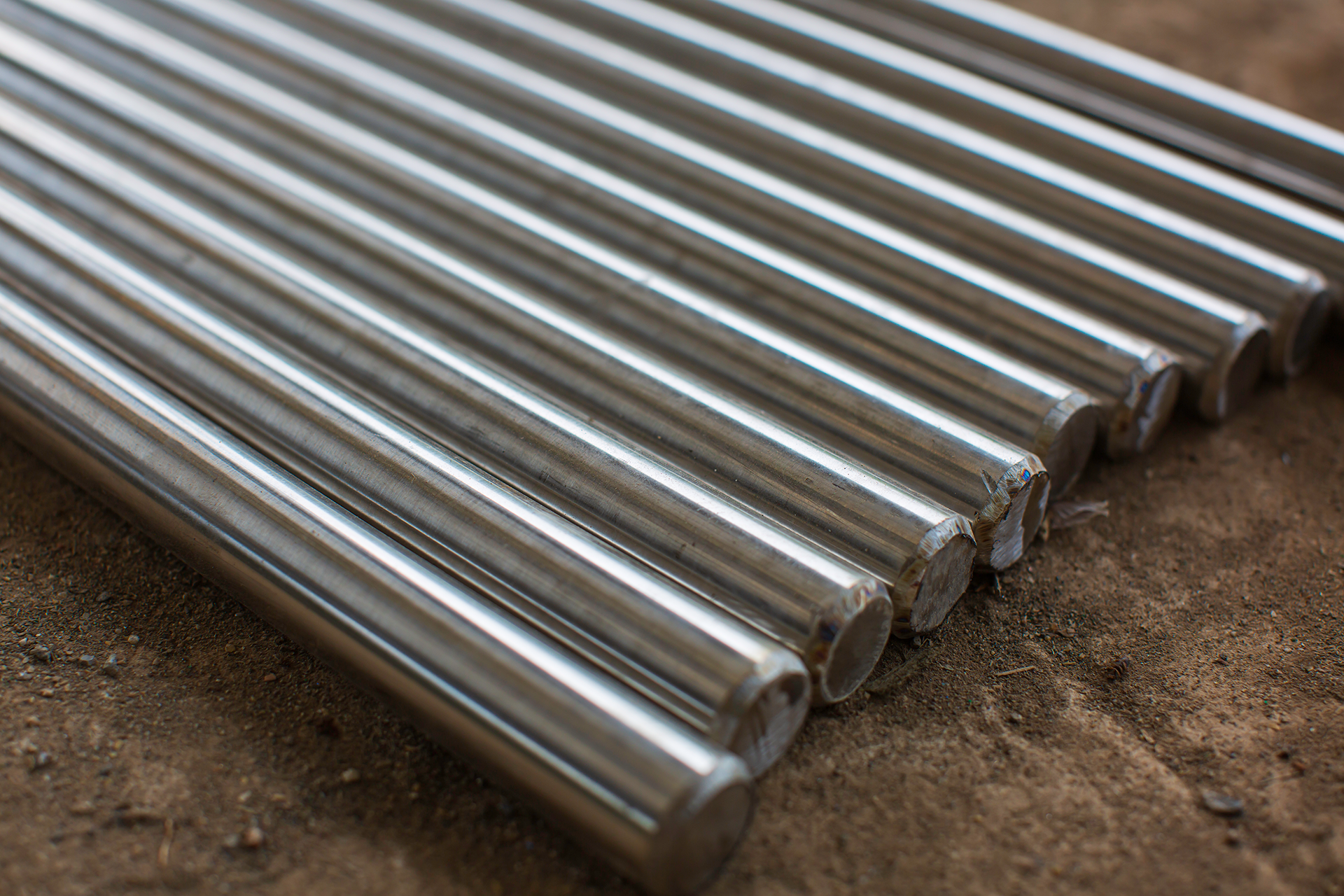

Why Aluminum Requires Precision Cutting

Aluminum is lightweight, corrosion-resistant, and highly machinable but its softness can present challenges during cutting. Inadequate cutting methods can cause burrs, heat distortion, or surface imperfections that interfere with fit, welding, or surface finishing. Using the right cutting method not only ensures accuracy but minimizes rework, speeds up fabrication, and preserves the integrity of the metal.

At Action Stainless, we process grades such as 1100, 3003, and 6061, which each respond differently to cutting operations. Whether you're fabricating marine-grade 6061 components or food-grade trays from 1100, precise cutting supports successful project outcomes.

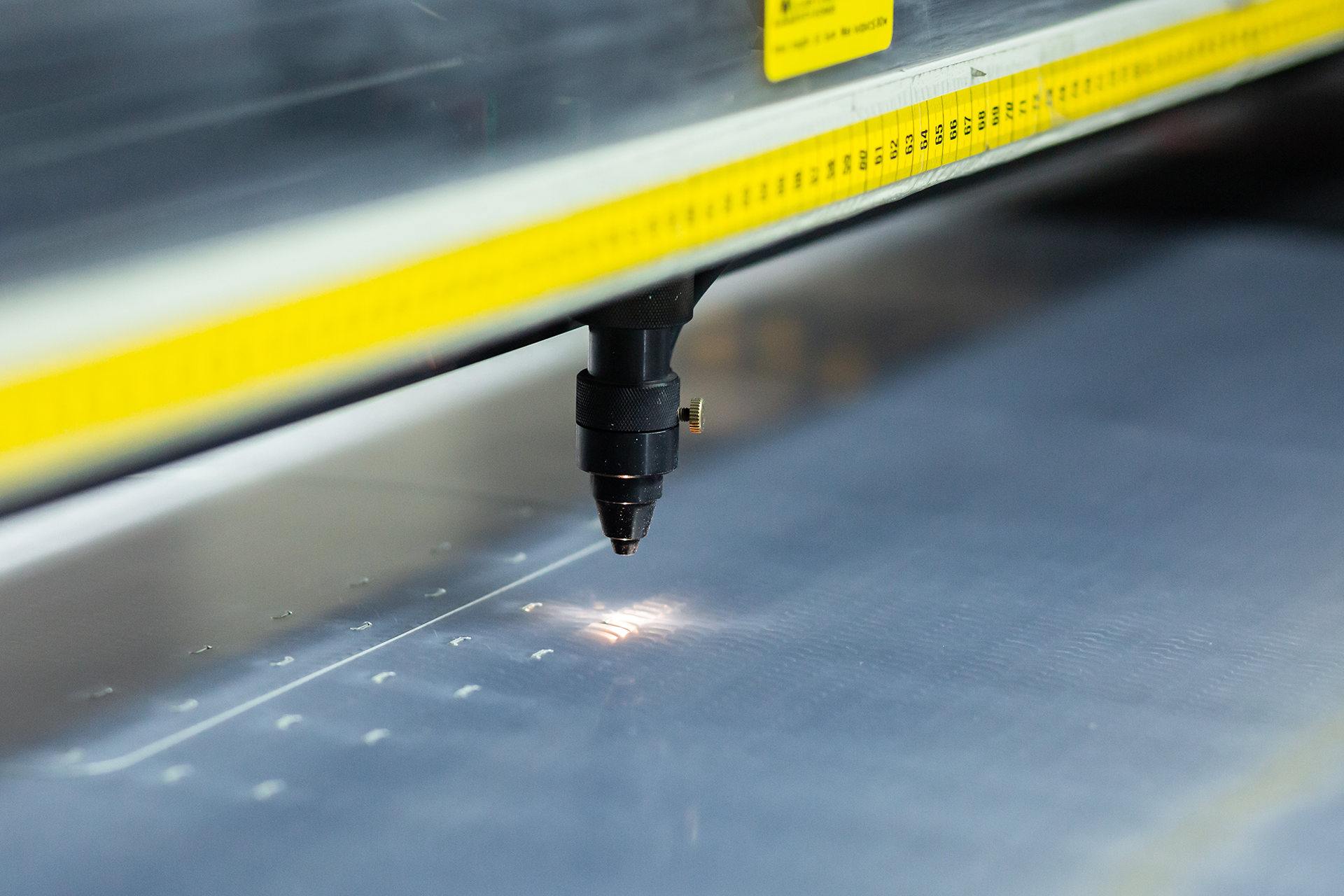

Waterjet Cutting: Non-Thermal Precision

Waterjet cutting uses a high-pressure stream of water mixed with abrasive material to cut through aluminum with exceptional precision. Because the process does not generate heat, it eliminates the risk of warping or heat-affected zones (HAZ).

Key Benefits:

- No heat distortion: Ideal for materials sensitive to temperature changes.

- Tight tolerances: Capable of cutting complex shapes with tolerances as close as ±0.005”.

- Smooth edges: Leaves a burr-free finish that reduces post-processing.

- Supports thick and thin stock: Effective across a range of thicknesses.

Ideal Applications: Waterjet is especially suited for applications that demand tight tolerances and clean edges. This includes sanitary food processing components, detailed flanges and gaskets, and architectural panels where finish quality is critical.

Waterjet Limits:

- Slower than saw cutting for long, straight runs

- Higher operational cost per inch for simple cuts

Waterjet cutting is most valuable when tolerance, material integrity, and complex geometry are priorities. It is particularly effective when cutting aluminum parts that must not be exposed to thermal deformation, such as high-precision machine covers or enclosures.

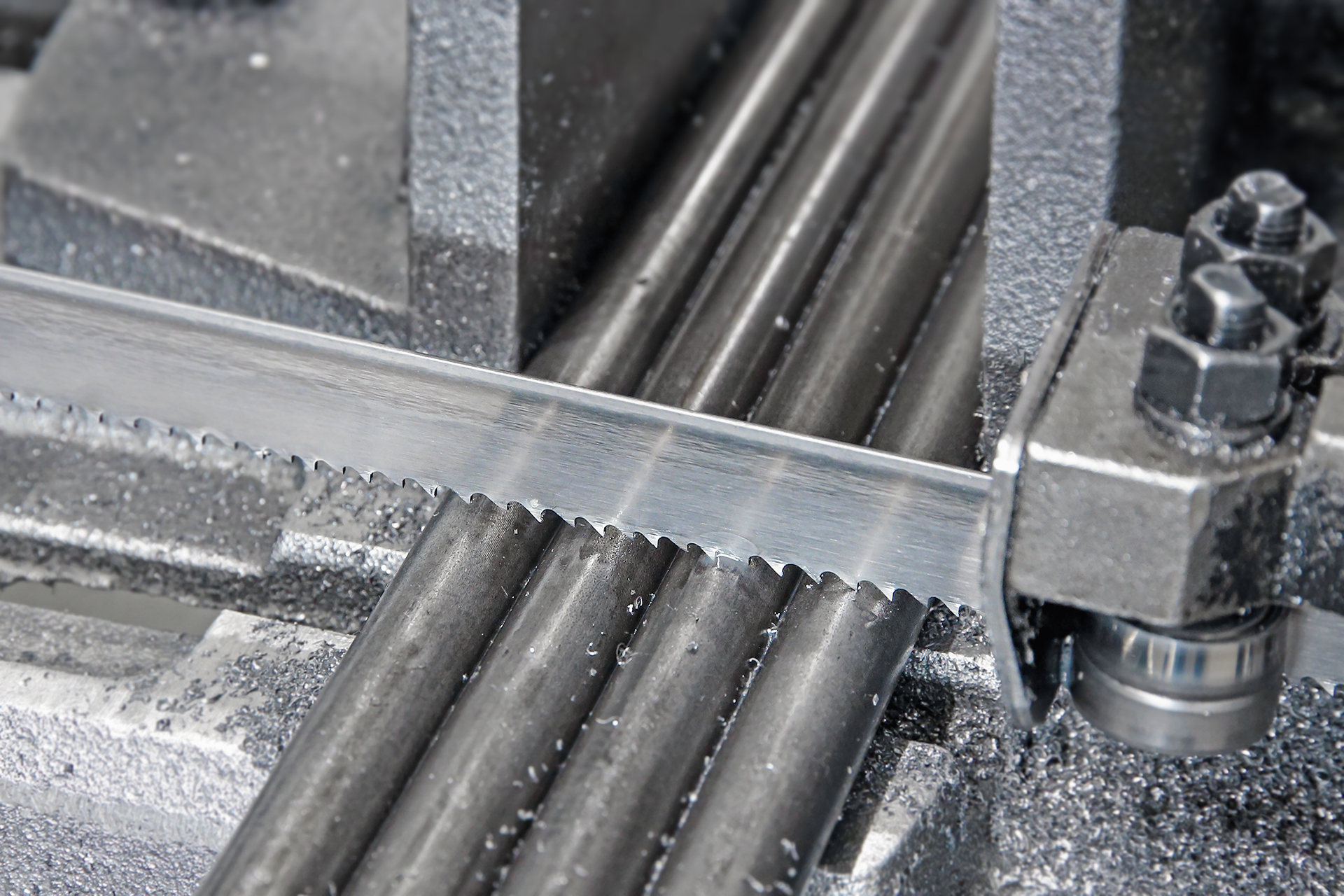

Saw Cutting: Speed and Consistency

Saw cutting remains one of the most efficient methods for processing aluminum sheet, plate, bar, and tube. At Action Stainless, we operate precision saws capable of cutting material up to 17" OD and 22 feet in length.

Key Benefits:

- Fast throughput: Excellent for straight-line cuts and high-volume orders.

- Clean, square edges: Reduces finishing time and supports accurate welding.

- Low cost: More economical than waterjet for simpler jobs.

- Minimal waste: Optimized nesting and material yield.

Ideal Applications: Saw cutting is ideal for simple, repeatable cuts needed in manufacturing and construction. These include structural aluminum supports, plates for chassis assemblies, and truck-bed frame components.

Saw Cutting Considerations:

- Less effective for intricate profiles

- May introduce slight burring on softer alloys like 1100

When speed and cost-effectiveness are critical and the part geometry is straightforward, saw cutting is the go-to solution.

Choosing the Right Method for Your Project

The decision between saw cutting and waterjet should be guided by material thickness, tolerances, part complexity, and production volume. Here’s a simplified comparison:

| Feature | Waterjet Cutting | Saw Cutting |

|---|---|---|

| Heat Affected Zone | None | Minimal |

| Tolerances | ±0.005" | ±0.030" typical |

| Cutting Speed | Moderate | High |

| Complexity | Excellent for shapes | Best for straight cuts |

| Cost Efficiency | Higher for short runs | Best for high volume |

While both methods have unique strengths, the best option depends on what matters most to your project: speed, precision, cost, or edge quality.

Enhanced Support Through In-House Processing

Action Stainless is more than a material supplier, we’re your processing partner. Our aluminum cutting services are performed in-house by trained operators using well-maintained equipment designed for tight tolerances and clean results.

Our aluminum cutting services include:

- Custom saw-cut blanks for structural and OEM use

- Waterjet-cut trays, enclosures, covers, flanges, and brackets

- Precision shearing and forming for panel-based designs

- CNC machining for hole patterns, countersinks, and slotted designs

We ensure all parts are deburred and inspected before shipment. Whether you’re working from a CAD drawing or physical template, our team can translate your design into precise aluminum parts with consistent quality.

Material Traceability and Quality Control

For projects requiring documentation and compliance, we offer full traceability for all aluminum products. Mill test reports (MTRs) are available upon request, and our quality control team inspects every cut part to meet project specifications.

Our services align with ISO-aligned best practices for industrial fabrication. For industries like medical equipment, food and beverage, or defense, material compliance and consistency are non-negotiable.

Industries That Rely on Our Aluminum Cutting Services

Action Stainless serves fabricators and manufacturers across a range of industries, including:

- Food and Beverage: Sanitary-grade trays, prep tables, machine guards

- Marine and Coastal: Corrosion-resistant panels, supports, and brackets

- HVAC & Construction: Duct panels, architectural trim, framing channels

- OEM Production: Custom parts for equipment enclosures, cabinets, conveyors

- Signage and Displays: Polished 1100 aluminum cut to shape for interior or exterior use

- Utilities and Infrastructure: Covers, barriers, and mounting panels

With aluminum grades 1100, 3003, and 6061 in stock and ready for fast turnaround, we ensure short lead times and dependable results.

Real-World Applications in Aluminum Cutting

Food Processing Line Trays: 1100 aluminum trays for sanitary prep tables, cut using waterjet for clean edges and easy sanitation.

Truck Bed Frames: 6061 plate saw-cut to precise lengths for strong, lightweight chassis systems.

HVAC Panels: 3003 sheet used for ducting and enclosures, shaped using a combination of shear cutting and press brake forming.

Control Cabinet Covers: Precision waterjet-cut 3003 panels with machined holes and countersinks for electrical enclosures.

Need Help Planning Your Next Aluminum Cut?

Whether you need long-run structural pieces or complex-shaped aluminum components, Action Stainless has the tools, people, and inventory to get the job done right. Let us help you choose the ideal cutting service to meet your performance, timeline, and budget goals.

Contact our team today to request a quote or learn more about our waterjet and saw cutting services for aluminum.