Value-Added Services That Enhance Stainless Steel Fabrication in 2025

When it comes to stainless steel fabrication, the quality of material is only part of the equation. Precision processing, value-added capabilities, and expert service can make all the difference in how efficiently and accurately your project comes together. At Action Stainless, our in-house value-added services are engineered to give customers a competitive edge by improving turnaround, enhancing precision, and reducing costs on-site.

This article highlights the top stainless steel fabrication services shaping industrial manufacturing and OEM success in 2025.

What Are Value-Added Metal Services?

Value-added metal services refer to secondary processes performed on raw stainless steel stock to prepare it for specific use in a final product. These services minimize the need for additional fabrication downstream and help customers receive components ready to assemble, weld, or install.

At Action Stainless, our capabilities include:

- Saw Cutting

- Waterjet and Laser Cutting

- CNC Milling and Turning

- Press Brake Forming

- Plate Rolling

- Shear Cutting

- Centerless Grinding

- Plasma Cutting

- Robotic Welding

- Polishing and Finishing

Each of these processes is supported by a team of specialists and high-performance equipment, ensuring accuracy and consistency from order to delivery.

Why These Services Matter in 2025

In 2025, industries are facing tighter deadlines, increasing demand for high-precision assemblies, and rising material costs. As a result, fabrication partners that can deliver pre-processed, high-accuracy stainless steel components are in greater demand than ever. Value-added services not only improve production efficiency but also reduce the need for downstream correction or in-house machining.

By providing fabrication-ready parts, Action Stainless helps customers reduce downtime, limit material waste, and accelerate assembly and welding schedules. Our investments in advanced cutting and forming equipment ensure that we can handle everything from high-volume production to custom stainless components for critical industries.

Key Benefits of Action Stainless Value-Added Services

1. Reduced Lead Times

Customers save time by outsourcing complex cuts, shaping, or finishing to our in-house team rather than relying on third-party vendors or additional shop work. Because our materials and services are under one roof, we shorten the total time from order to delivery.

2. Greater Dimensional Accuracy

Laser, waterjet, and CNC services ensure tight tolerances on everything from tube notching to bracket fabrication. This reduces rework and ensures proper fit in assembly lines. In industries where precision is non-negotiable, like medical equipment or food-grade piping, this consistency becomes a competitive advantage.

3. Lower Project Costs

By delivering ready-to-assemble components, we reduce labor, material handling, and waste. Customers benefit from fewer rejected parts and less need for finishing work, leading to leaner production cycles and better margins.

4. Seamless Integration with Stainless Supply

All value-added services are performed at the same facilities where we maintain extensive inventories of stainless steel sheet, plate, pipe, and tube. This integration reduces logistics costs and ensures that material specifications are precisely matched with the intended process.

5. Support for Custom and High-Mix Projects

Whether fabricating sanitary tubing for a food processor or producing multiple formed parts for OEM assembly, Action Stainless adapts to customer requirements. Our advanced processing systems and expert operators provide the flexibility needed for both one-off and recurring work.

Fabrication Services We Offer in 2025

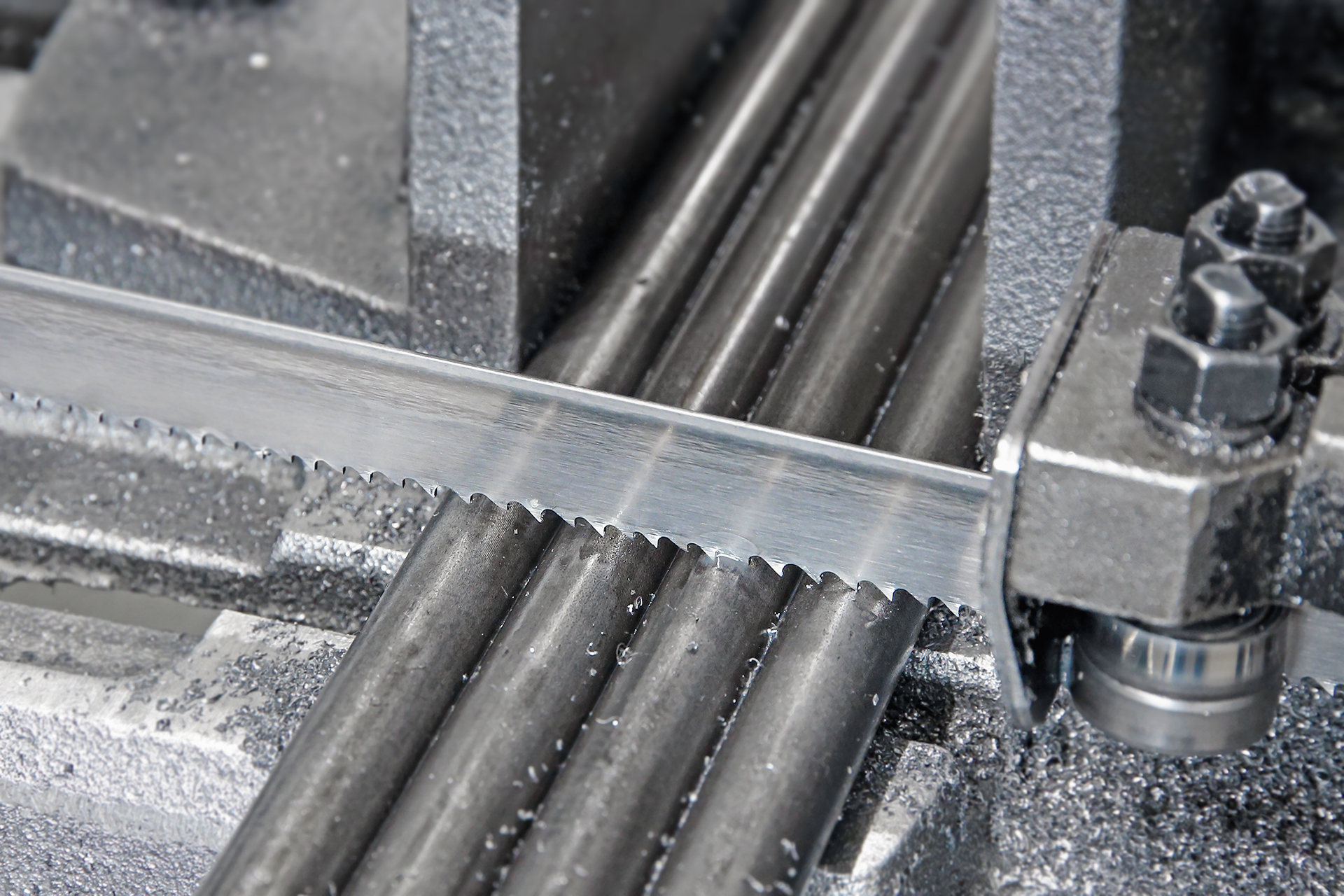

We provide accurate saw cutting for stainless steel pipe, tube, and bar, up to 17" OD and 22' lengths. Clean, burr-free cuts support immediate weld prep and eliminate the need for secondary cleaning.

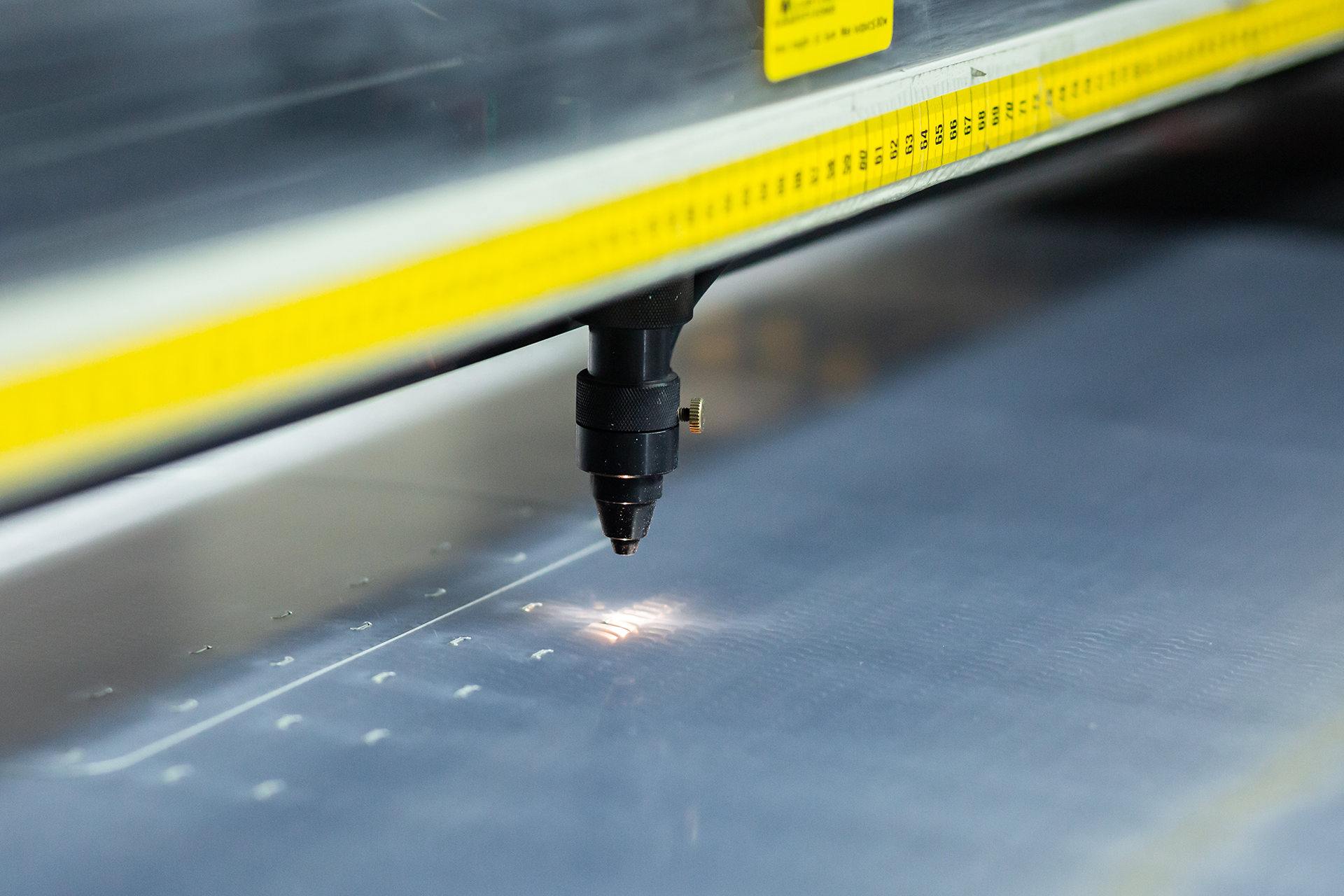

Waterjet cutting uses high-pressure abrasive water streams to cut stainless sheet and plate without introducing heat distortion. Laser cutting, on the other hand, delivers exceptional speed and fine-detail accuracy for components that demand intricate geometry or clean edges.

Our CNC machining services allow for complex geometries, tight tolerances, and consistent repeatability. We fabricate custom brackets, flanges, and structural fittings that are ready for immediate use in your assemblies.

Using hydraulic press brake equipment, we form stainless sheet and plate to exact angles. Applications include panels, trays, guards, and housings used across industrial equipment and food-grade machinery.

For tanks, vessels, and curved parts, our rolling services form plate to custom diameters. Shearing provides clean, straight cuts on flat sheet stock, ideal for parts with minimal secondary processing.

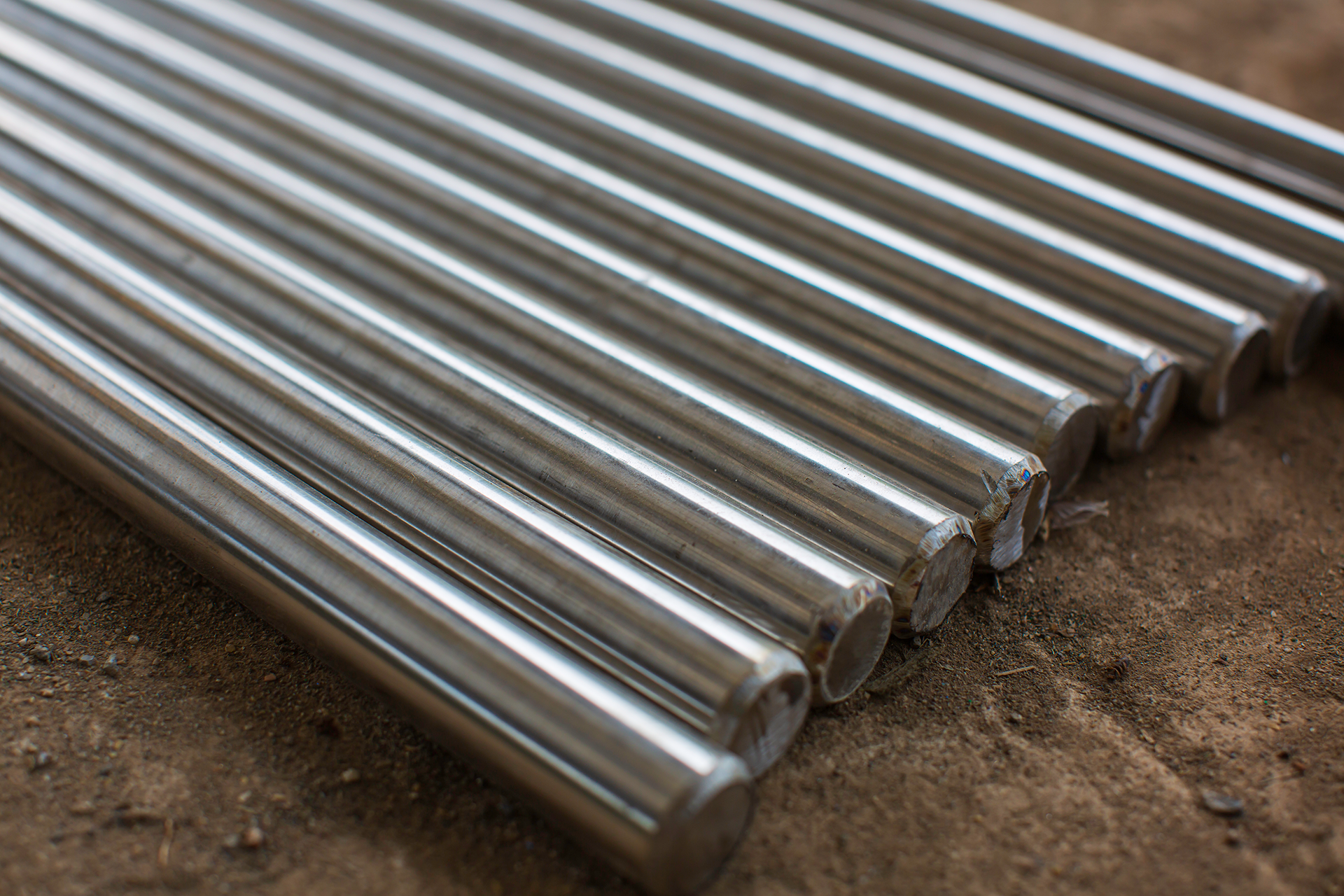

Centerless Grinding

Precision-ground stainless bar improves straightness and roundness, especially for rotary applications like pump shafts, conveyors, and agitators. We maintain pump shaft-quality inventory and provide centerless grinding services in-house.

Robotic Welding

Robotic welders improve consistency and reduce weld times in batch and volume production. Automated welding is especially beneficial when working with stainless steel, where distortion and surface quality are key concerns.

Polishing & Finishing

For applications that require sanitary or architectural finishes, our polishing services produce a consistent surface with reduced roughness (Ra). Finishes can be tailored to FDA, NSF, or visual standards depending on the project.

Industries We Serve With Value-Added Services

Our fabrication support extends across critical industries:

- Food and Beverage Processing: Sanitary cuts, polished tubing, and CIP-ready components.

- Oil & Gas: Precision-formed tanks and structural piping support systems.

- Water & Wastewater Treatment: Weld-prepped piping and corrosion-resistant fittings.

- Marine & Coastal Infrastructure: Custom-rolled plate and polished railing components.

- OEM Equipment Manufacturing: Tight-tolerance structural brackets and machine parts.

- Pharmaceutical Systems: High-purity tubing and components with verified finishes.

With in-house material and service capabilities, we help customers meet industry standards and shorten project timelines.

How Our Services Help Streamline Projects

Rather than coordinating multiple suppliers for material, cutting, and machining, Action Stainless customers work with a single source. This simplifies planning, improves accountability, and ensures consistency from batch to batch. With full traceability on materials and advanced QC processes on fabricated components, you can move forward with confidence.

We understand the pressures of industrial schedules, from maintenance shutdowns to new product development. Our service teams are equipped to respond quickly and adjust production schedules to help meet critical deadlines without sacrificing quality.

Partner With Action Stainless

If your business relies on stainless steel fabrication, partnering with a supplier that offers integrated value-added services delivers a clear advantage. At Action Stainless, we combine trusted inventory with advanced processing and expert consultation, so your materials show up ready to perform.

Ready to improve your next project’s efficiency?

Contact Action Stainless to learn more about how our value-added services can reduce lead times, increase precision, and improve fabrication outcomes in 2025 and beyond.