Top 5 Benefits of Using Duplex Stainless Steel Over Carbon Steel

When choosing the right material for industrial projects involving structural strength, corrosion resistance, or pressurized systems, the debate between duplex stainless steel and carbon steel is a critical one. While carbon steel is widely used for its strength and affordability, duplex stainless steel delivers advanced performance in environments where durability, resistance to corrosion, and long-term cost efficiency matter most. At Action Stainless, we stock and process duplex stainless grades that serve demanding industries including wastewater, oil and gas, chemical processing, and marine applications.

What Is Duplex Stainless Steel?

Duplex stainless steel is a family of stainless alloys characterized by a balanced microstructure of austenite and ferrite. This dual-phase structure gives duplex stainless steel a combination of properties found in both ferritic and austenitic grades. It offers improved strength, excellent corrosion resistance, and better stress corrosion cracking resistance compared to standard stainless or carbon steels.

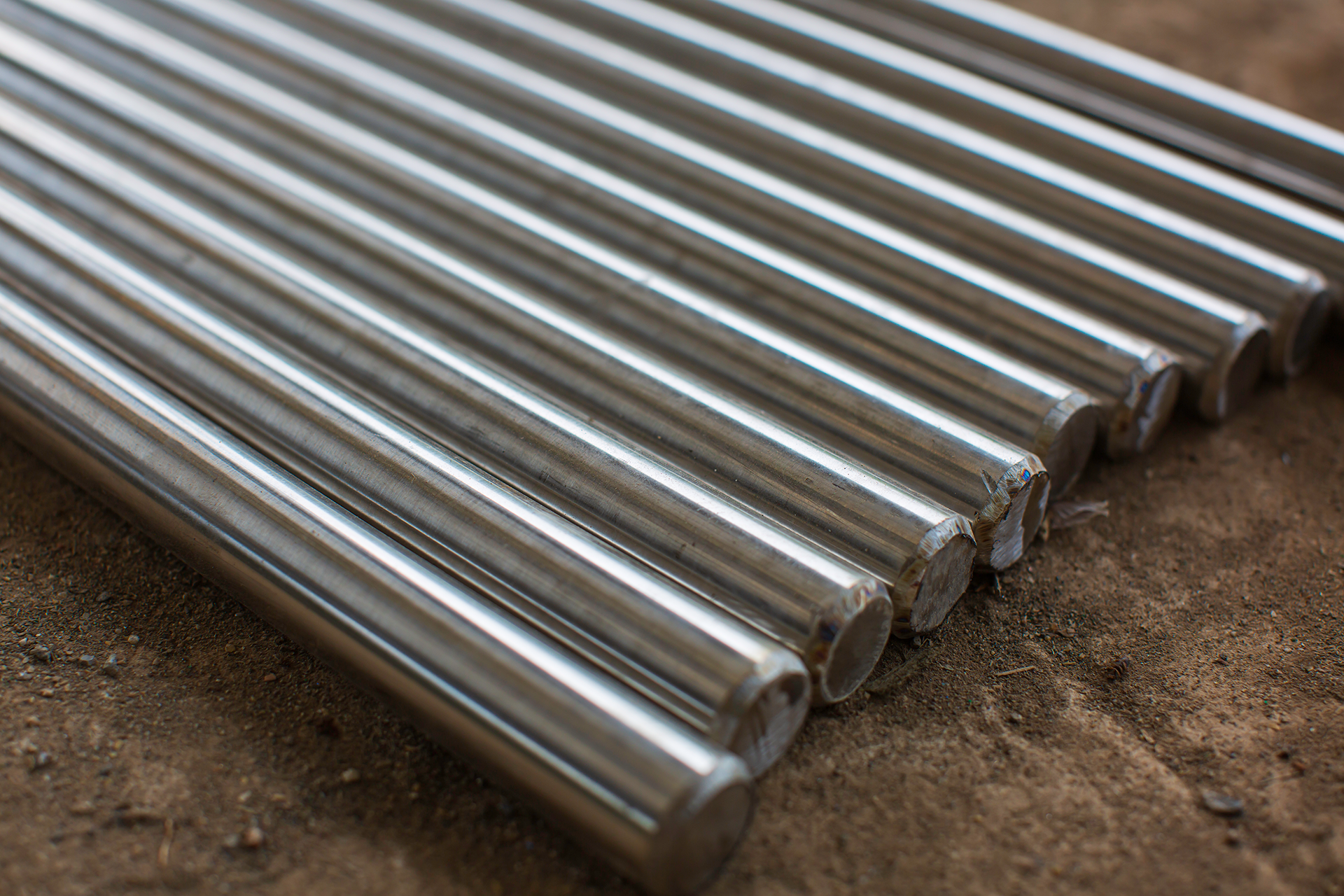

Common duplex grades include 2205 (UNS S32205) and 2507 (super duplex), both of which are designed for structural applications, piping systems, and environments where chloride stress corrosion is a concern.

At Action Stainless, our duplex stainless inventory supports heavy-duty use in corrosive and high-load environments, with available cutting and forming services for custom applications.

1. Superior Corrosion Resistance

One of the biggest advantages of duplex stainless steel over carbon steel is corrosion resistance. Duplex grades offer higher resistance to both general and localized corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in marine structures, offshore oil rigs, wastewater treatment facilities, and chemical storage systems.

Carbon steel, by contrast, requires protective coatings or linings to withstand corrosive environments. Without this extra layer of protection, carbon steel is vulnerable to rust and degradation, especially when exposed to moisture, salt, or chemicals.

2. Higher Mechanical Strength

Duplex stainless steel has significantly greater mechanical strength than carbon steel. This higher yield strength allows for thinner sections in construction and fabrication, reducing overall material weight and cost without compromising performance.

For example, 2205 duplex stainless has nearly twice the yield strength of 304 or 316 stainless steel, and outperforms carbon steel in load-bearing applications. This makes it an ideal choice for pressure vessels, support frames, and structural components that require long-term durability.

3. Improved Lifespan and Lower Maintenance

While the upfront cost of duplex stainless may be higher than carbon steel, its lifecycle cost is often lower. Duplex alloys require less frequent replacement, repair, or maintenance due to their durability and corrosion resistance. In food processing plants, chemical transport systems, or coastal infrastructure, the ability to withstand harsh conditions translates to longer service life and lower operating costs.

Carbon steel, even when painted or galvanized, eventually corrodes and weakens over time. This leads to higher maintenance budgets, downtime for replacements, and potential safety risks in critical systems.

4. Better Stress Corrosion Cracking Resistance

In chloride-rich environments, such as seawater systems or wastewater facilities, stress corrosion cracking (SCC) can be a serious concern. Duplex stainless steels offer superior SCC resistance due to their ferritic-austenitic structure. This resistance is especially important in environments where high temperatures, tensile stress, and chlorides intersect.

Carbon steel, on the other hand, has very limited SCC resistance and often cannot be used in such applications without advanced coatings or design modifications.

5. Versatility Across Industrial Applications

Duplex stainless steel serves a broad range of industries due to its unique combination of strength, corrosion resistance, and cost efficiency. At Action Stainless, we regularly supply duplex grades to customers in:

- Water and wastewater treatment plants

- Offshore oil and gas production

- Pulp and paper manufacturing

- Marine and shipbuilding

- Power generation and chemical refining

These industries demand high-performance materials that can withstand constant exposure to aggressive media, fluctuating temperatures, and structural loads. Duplex stainless steel delivers reliability in all of these areas.

Processing Duplex Stainless Steel at Action Stainless

Working with duplex stainless requires experience and precision. At Action Stainless, our team is equipped to process duplex material using advanced in-house services:

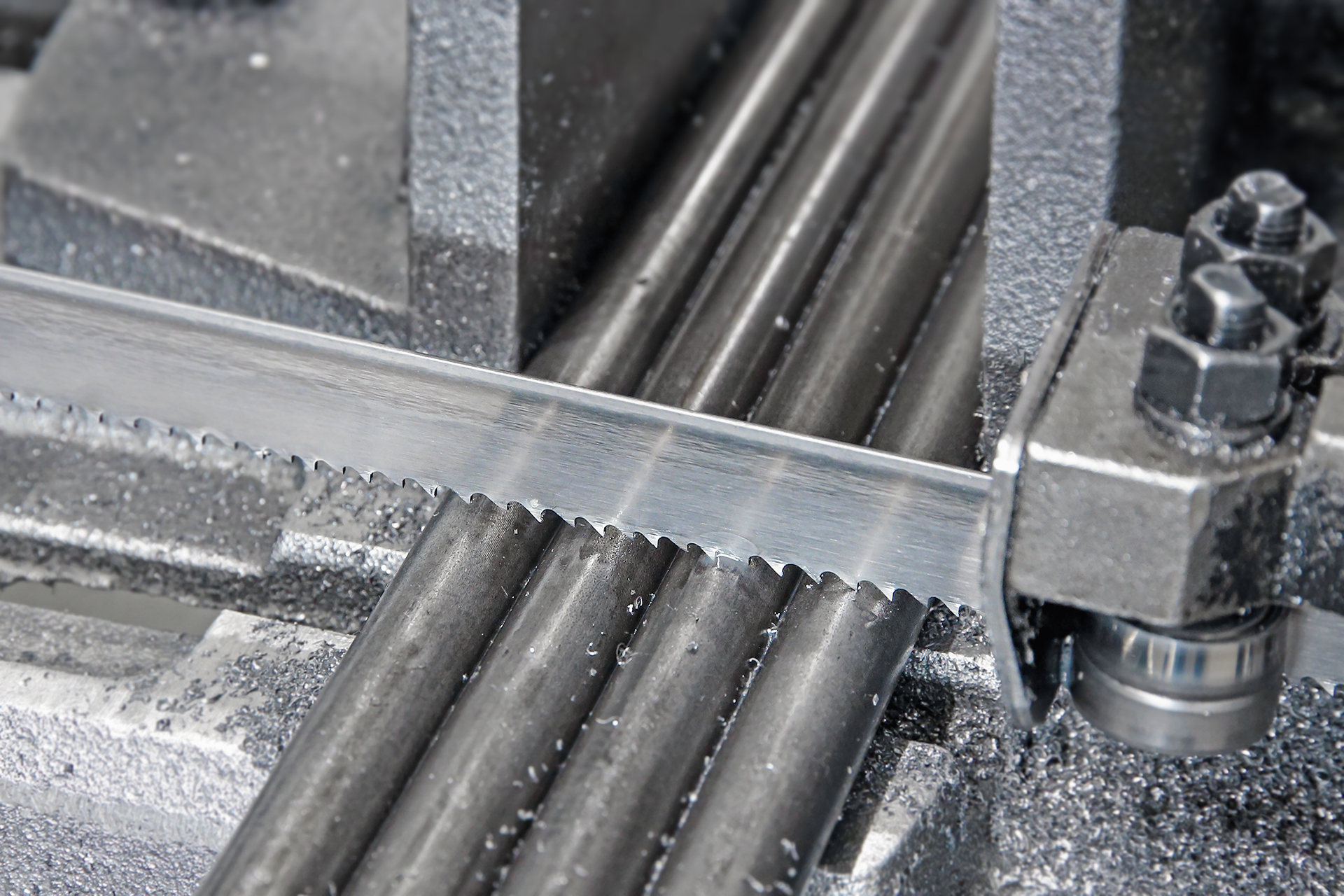

- Saw Cutting: Accurate length cuts for structural or piping use

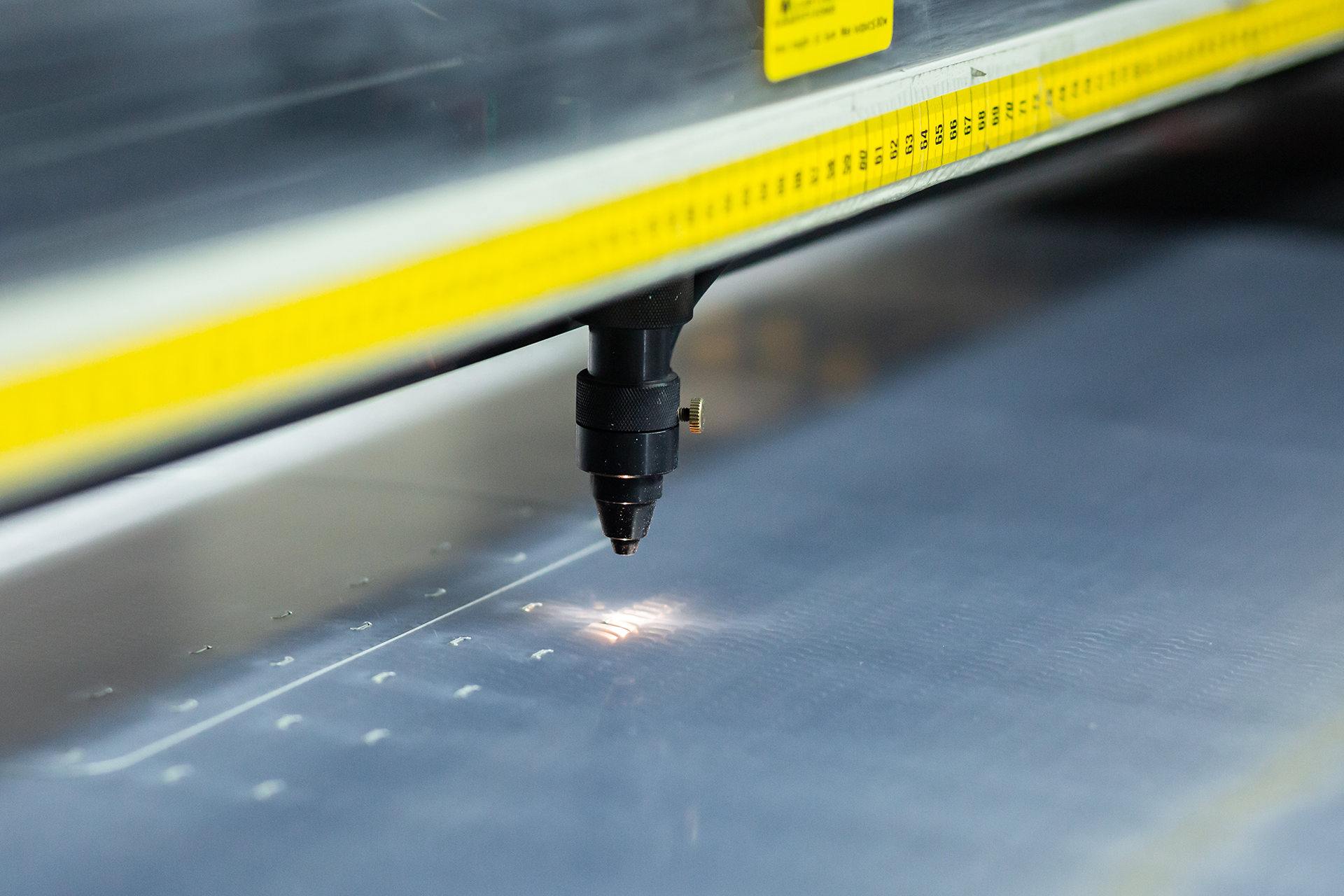

- Waterjet & Plasma Cutting: Smooth edges with minimal heat distortion

- Press Brake Forming: Ideal for bending thick duplex plate

- Custom Fabrication Support: Assistance for OEMs, contractors, and industrial clients

Our duplex stainless sheet and plate are available in thicknesses and grades suited for industrial fabrication. We maintain traceability with mill test reports and can provide polished finishes or edge prep depending on the application.

| Feature | Carbon Steel | Duplex Stainless Steel |

|---|---|---|

| Corrosion Resistance | Low | High |

| Mechanical Strength | Moderate | High |

| Weight | Higher sections | Thinner sections possible |

| SCC Resistance | Poor | Excellent |

| Maintenance Requirements | Frequent | Minimal |

| Lifecycle Cost | Higher long-term | Lower long-term |

Trust Action Stainless for Duplex Solutions

Whether you're building fluid handling systems, pressure vessels, or structural supports, Action Stainless offers duplex stainless steel solutions that outperform carbon steel in challenging environments. Our stock, processing capabilities, and expertise in stainless alloys make us the go-to partner for industrial customers across sectors.

Looking for corrosion-resistant steel for your next project?

Contact Action Stainless today to discuss available duplex stainless steel grades, custom cutting options, and processing services.