Why 316 Stainless Steel Is the Preferred Choice for Food & Beverage Equipment

When it comes to food and beverage manufacturing, not all stainless steel is created equal. While grades like 304 are widely used in industrial and commercial environments, 316 stainless steel is the industry standard for critical food processing applications. Its superior corrosion resistance, high durability, and hygienic properties make it the preferred material for manufacturers focused on safety, longevity, and compliance. At Action Stainless, we offer in-stock 316 and 316L stainless steel in sheet, plate, and tube form to support high-performance processing systems.

What Makes 316 Stainless Steel Food-Grade?

316 stainless steel is an austenitic chromium-nickel alloy with an added element: molybdenum. This addition significantly boosts corrosion resistance, especially in environments with high chloride exposure, such as those involving salt, brine, acidic foods, or harsh cleaning chemicals. In comparison to 304 stainless steel, which is highly resistant but more vulnerable to pitting in chloride-rich conditions, 316 provides a stronger line of defense against localized corrosion.

Food processing environments are constantly exposed to moisture, varying pH levels, and rigorous cleaning protocols. Grade 316 maintains structural integrity and a cleanable surface finish even under frequent sanitation with caustic or acidic agents. This corrosion resistance is one of the main reasons food equipment designers rely on it.

At Action Stainless, our 316 stainless steel sheets and plates meet the exacting requirements of food safety systems, offering smooth surfaces that can be further polished for sanitary applications.

How 316 Meets FDA and USDA Guidelines

Food-grade materials must meet federal safety regulations for cleanability, corrosion resistance, and non-reactivity. According to the FDA Food Code and USDA equipment standards, surfaces that contact food must be non-toxic, non-absorbent, and easily cleanable. Stainless steel specifically grades like 316 and 316L meets or exceeds these criteria.

316 stainless steel provides:

- Resistance to biological contamination

- Smooth, non-porous surfaces for easy sanitizing

- Compatibility with washdowns using acidic or alkaline cleaning agents

Its use helps ensure HACCP (Hazard Analysis and Critical Control Point) compliance, a cornerstone of food safety programs. Action Stainless provides full traceability for its 316 stainless materials, helping food processors document compliance and maintain quality assurance.

Performance in High-Moisture and Aggressive Environments

Whether it's a dairy facility, brewery, or seafood processing plant, moisture is ever-present. 316 stainless steel stands up to this challenge, offering protection against rust and chemical degradation in wet or steamy environments.

Applications that commonly demand 316 stainless include:

- Acidic food contact (tomato, citrus, wine, vinegar)

- Salt-rich processes (pickling, brining, seafood packaging)

- Steam sterilization or high-heat cleaning

In addition to sheet and plate, Action Stainless stocks 316 tubing used in transfer lines, CIP systems, spray headers, and frame structures exposed to humidity and condensation.

Differences Between 316 and 316L in Processing

Both 316 and 316L are widely used in food equipment, but they differ slightly in carbon content. 316L contains lower carbon, making it more resistant to sensitization and intergranular corrosion after welding. This is important for fabricators who weld tanks, pipe systems, or framework.

Lower carbon content also enhances formability, allowing tighter bends or complex geometries without compromising corrosion resistance. For equipment that undergoes repeated cleaning and thermal cycling, 316L is often preferred for its weld-friendly properties.

Fabrication Advantages for Food Equipment Manufacturers

316 stainless steel is highly machinable, formable, and weldable, giving manufacturers flexibility to create complex parts and equipment. At Action Stainless, our fabrication-ready inventory supports a range of production needs:

- Sheet & Plate: Ideal for tanks, countertops, splash guards, and food contact surfaces

- Tubing: Used in sanitary pipe systems, conveyors, fluid delivery systems

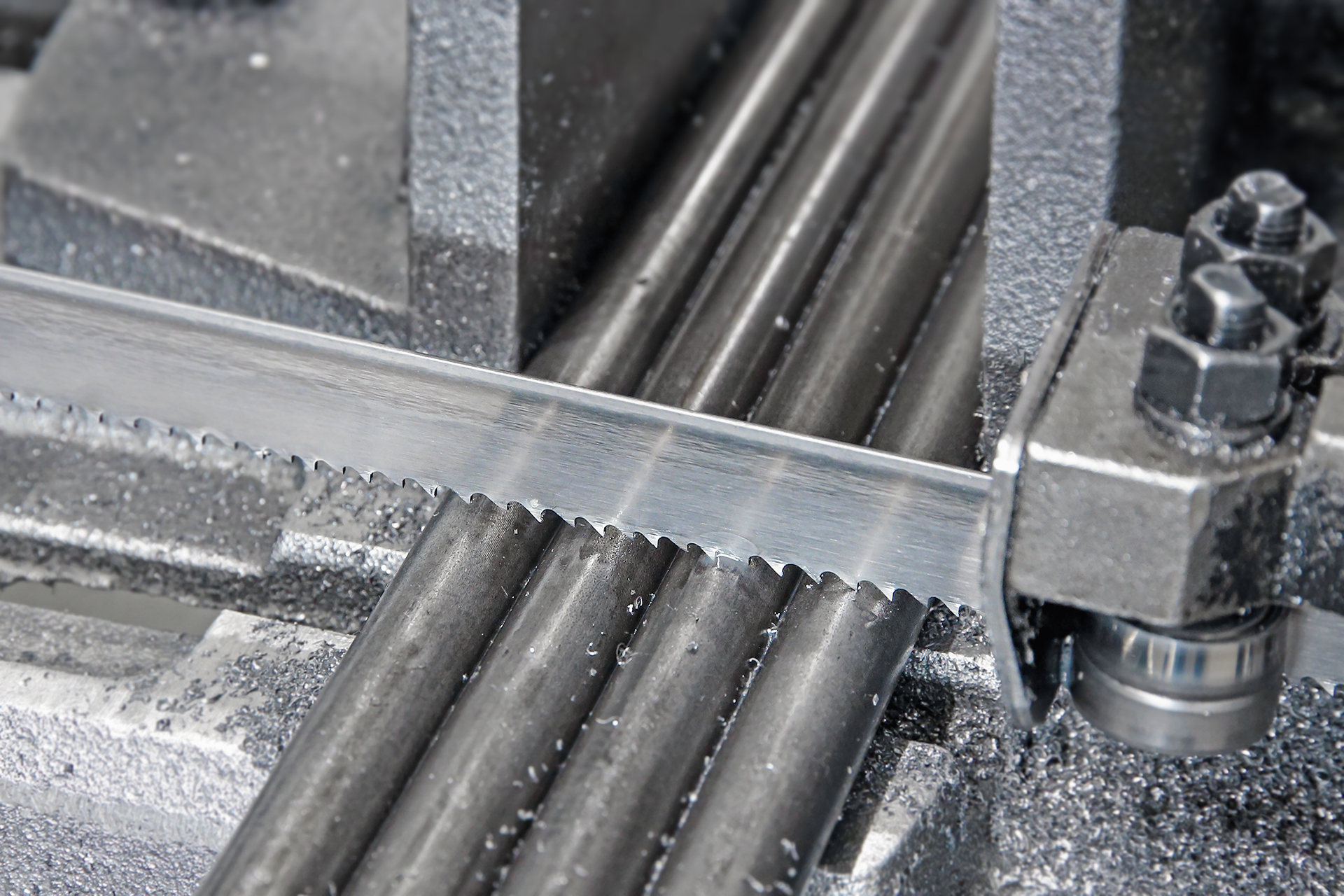

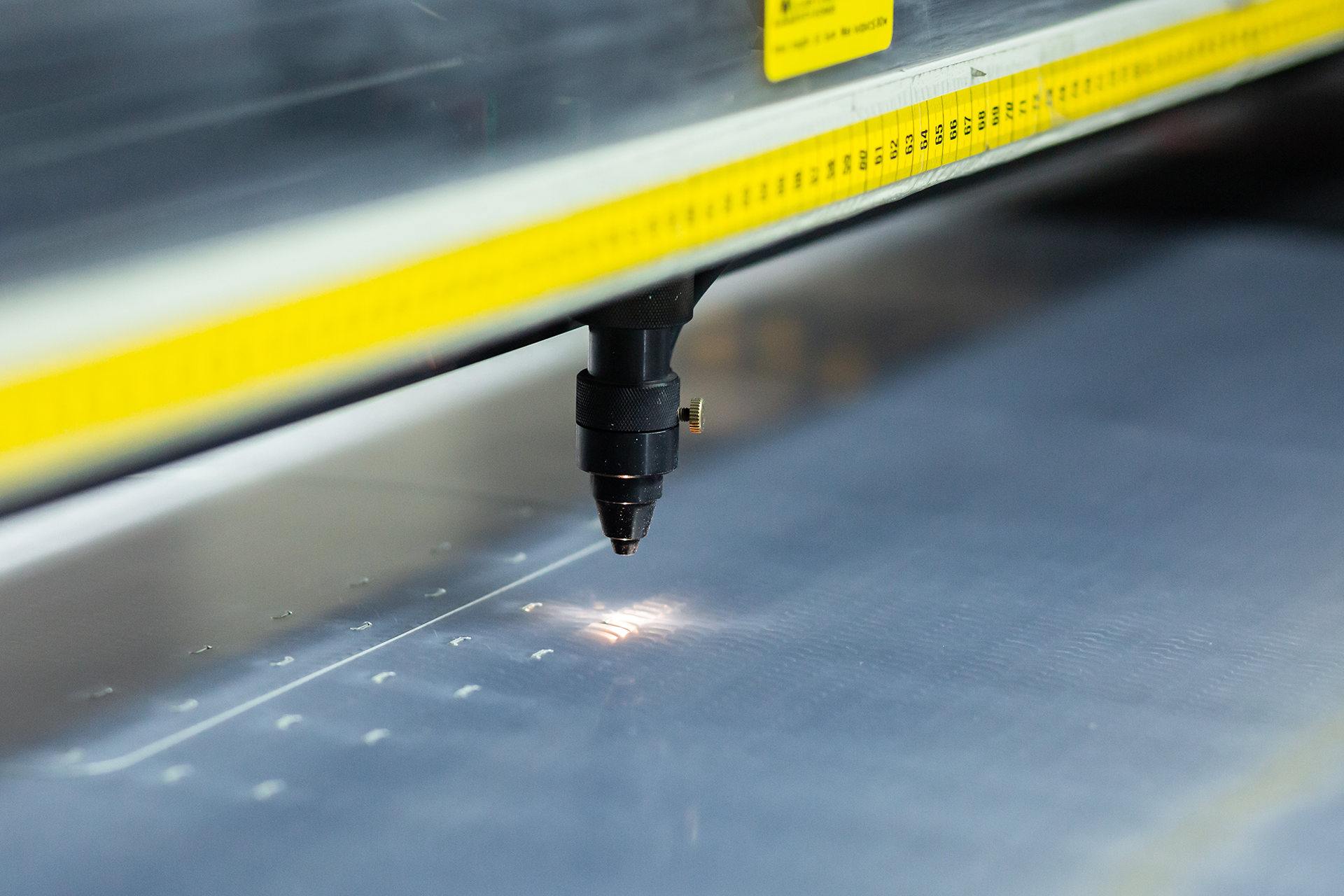

- Processing Services: Laser cutting, waterjet cutting, polishing, and precision shearing

Our in-house value-added services ensure 316 stainless parts arrive ready for integration into your processing systems. Whether you’re constructing new food-grade systems or upgrading legacy equipment, we provide the metal and machining to get it done.

Common Industries Using 316 Stainless Steel

From high-volume production plants to niche gourmet facilities, many segments of the food and beverage industry rely on 316 stainless steel to meet sanitary and structural performance requirements.

Industries include:

- Dairy and cheese processing

- Beverage production and bottling

- Brewing and distillation

- Seafood and meat packaging

- Commercial kitchens and central food service facilities

In these operations, 316 stainless steel performs reliably across washdowns, thermal exposure, and chemical use helping operators extend equipment life and reduce downtime.

Sourcing 316 Stainless from Action Stainless

Action Stainless supplies 316 and 316L stainless steel in multiple product forms, including:

- Sheet: In-stock in multiple gauges, ready for food-contact surface use

- Plate: For heavy-duty structural or tank fabrication

- Tubing: Round and square, sanitary-ready for conveyors, pipes, or handrails

We also offer polishing services to achieve finishes suitable for hygienic and decorative applications. Our team provides material selection guidance, ensuring you get the right grade and finish for your food equipment build.

All our 316 products come with mill test reports for traceability, supporting audit readiness and long-term performance assurance.

Work with a Trusted Stainless Steel Partner

Food and beverage operations can't afford downtime or quality lapses. Choosing 316 stainless steel for your equipment and working with a knowledgeable supplier can help you achieve regulatory compliance, reduce maintenance costs, and improve product quality.

At Action Stainless, we help food processors, OEMs, and contractors build better systems with certified stainless steel and reliable in-house services. Our inventory, experience, and commitment to quality make us a trusted partner to the food and beverage industry.

Ready to specify 316 stainless steel for your food or beverage project?

Contact your Action Stainless representative today to request a quote or learn more about in-stock 316 sheet, plate, and tubing options.